Integrated packaging LED display panel based on chip stacking

An integrated packaging and chip stacking technology, applied in the field of integrated packaging LED display panels, can solve the problems of easy de-soldering of welding pins, high pollution, and many out-of-control points of pixels, so as to solve the problem of out-of-pixel failure, reduce pollution emissions, pixel The effect of small spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with specific embodiment and accompanying drawing, the present invention is further elaborated and illustrated:

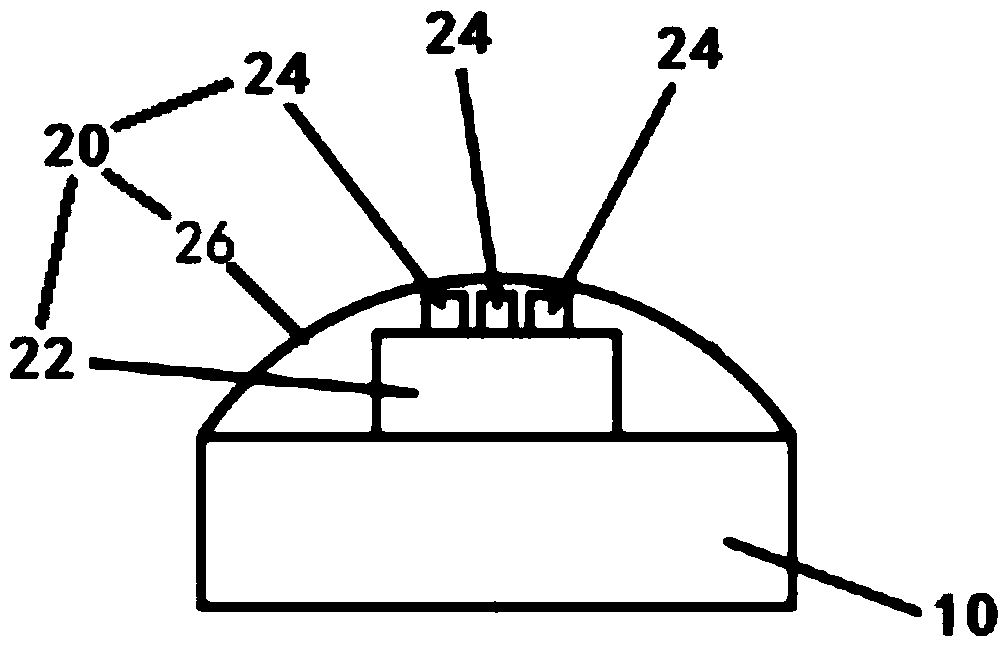

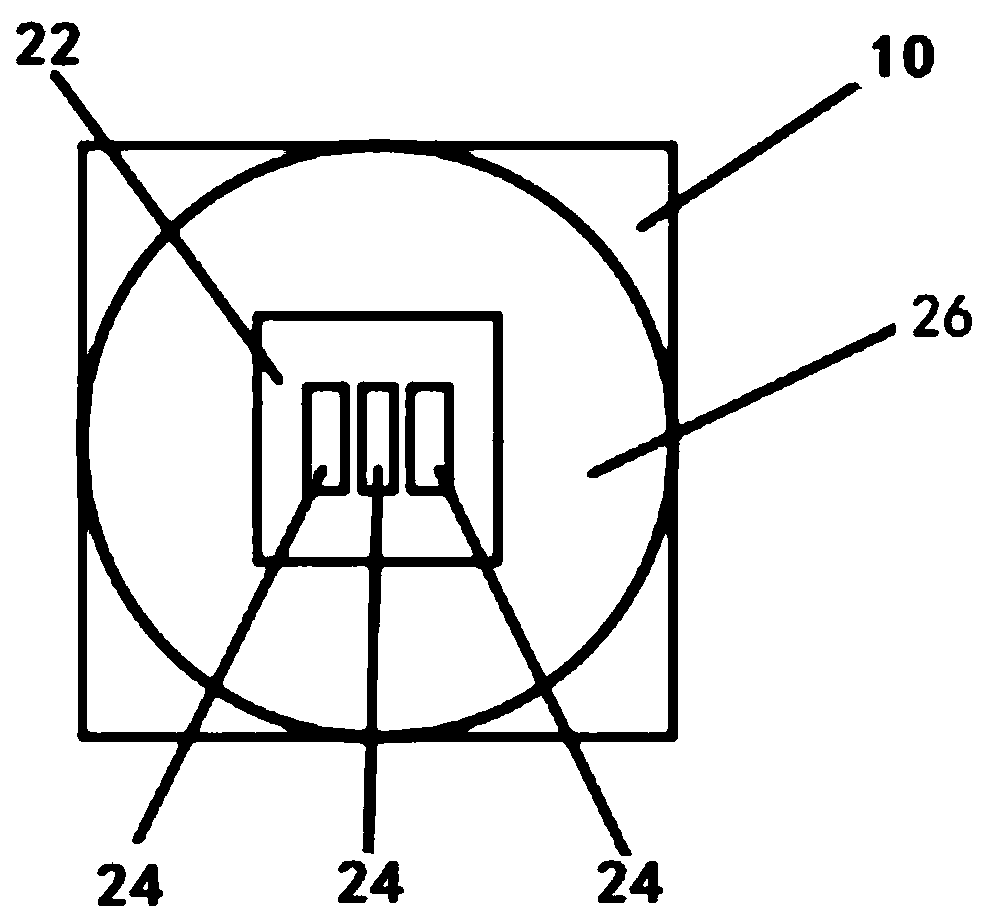

[0031] Please refer to figure 1 , figure 2 with image 3 , the integrated packaged LED display panel based on chip stacking includes an integrated packaged circuit board 10, and the integrated packaged circuit board is provided with at least two integrated packaged lamp beads 20 without support pins. The integrated packaged lamp bead 20 without support pins includes a driver IC bare chip 22, an LED bare chip 24 and an encapsulant 26, and the LED bare chip 24 is stacked on the upper surface of the driver IC bare chip 22 and connected to the driver IC bare chip 22. The bare IC chip 22 is electrically connected, and after the bare driver IC chip 22 is electrically connected to the integrated packaging circuit board 10 , the packaging compound 26 encapsulates the bare driver IC chip 22 and the bare LED chip 24 .

[0032] The LED die chip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com