A kind of sulfur cathode material with core-shell structure and preparation method thereof, lithium-sulfur battery positive electrode sheet and lithium-sulfur battery

A technology of sulfur cathode material and core-shell structure, which is applied in the field of lithium-sulfur batteries, can solve the problems of poor conductivity, capacity loss, and reduction of preparation costs of sulfur cathodes, and achieve improved rate performance, cost reduction, large specific surface area and porosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The present invention also proposes a method for preparing a sulfur cathode material, comprising the following steps:

[0049] S1: with Fe 2 o 3 Nanocubes were used as templates, and the Fe 2 o 3 The nanocube surface is coated with a layer of polydopamine polymer (PDA) to form Fe 3 o 4 @PDA nanocube, and Fe under inert atmosphere 3 o 4 @PDA nanocubes are sintered at high temperature to obtain carbon-coated ferric oxide nanocubes, denoted as Fe 3 o 4 @C;

[0050] Preferably, S1 specifically includes:

[0051] S11: Fe 2 o 3 Nanocubes were dispersed in deionized water and sonicated until uniformly dispersed; control of Fe 2 o 3 The ratio relationship between nanocubes and deionized water to ensure Fe 2 o 3 Nano cubes can be dispersed evenly;

[0052] S12: Add buffer and dopamine hydrochloride, stir, collect by centrifugation, and dry to obtain polydopamine-coated Fe 3 o 4 Nanocubes, denoted as Fe 3 o 4 @PDA; Dopamine hydrochloride will polymerize under ...

Embodiment 1

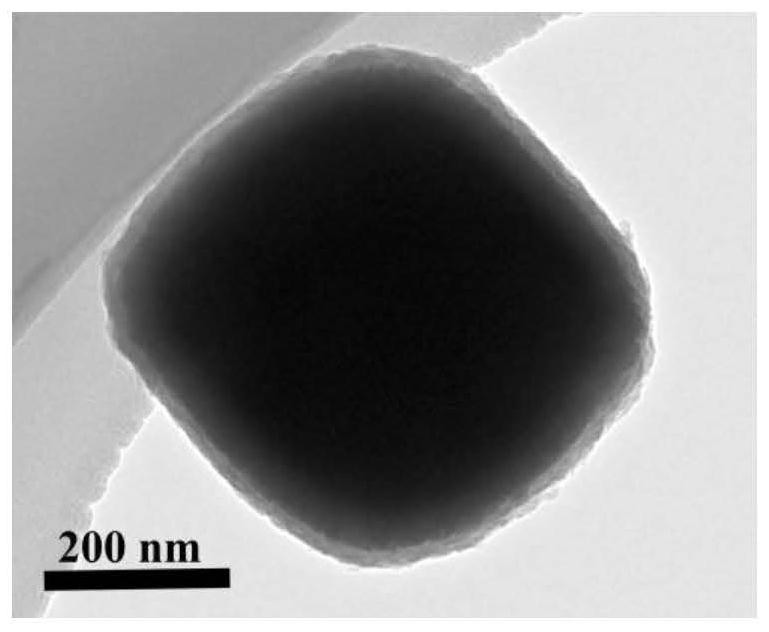

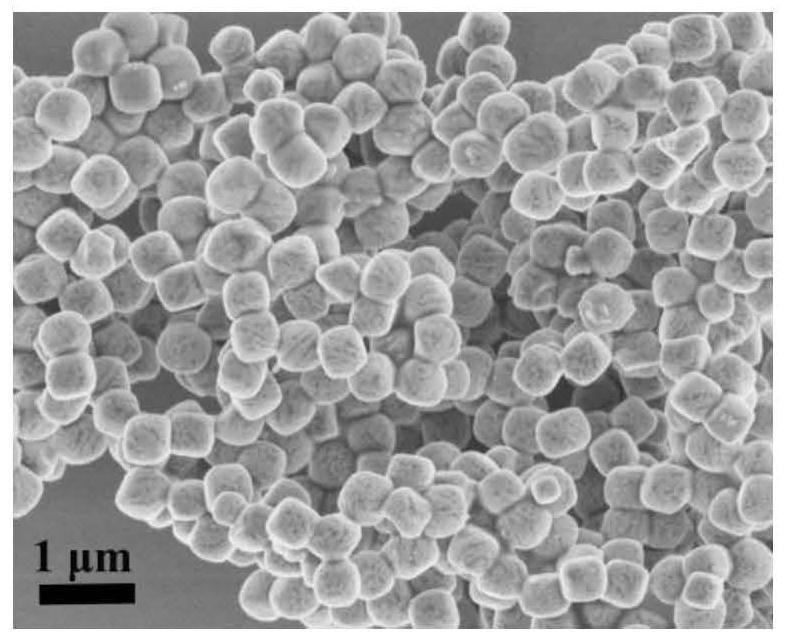

[0070] This embodiment provides a sulfur cathode material, the sulfur cathode material is a S / Fe core-shell structure 2 N@C composite nanocage, with carbon as the outer shell and iron nitride as the inner core; the sulfur cathode material also includes sulfur element, which is distributed on the inner wall of the outer shell and the surface of the inner core, denoted as S / Fe 2 N@C; the S / Fe 2 The size of N@C is between 400nm and 500nm.

[0071] This embodiment also provides a method for preparing a sulfur cathode material, comprising the following steps:

[0072] S1: carbon-coated ferric oxide (Fe 3 o 4 @C) preparation of nanocubes;

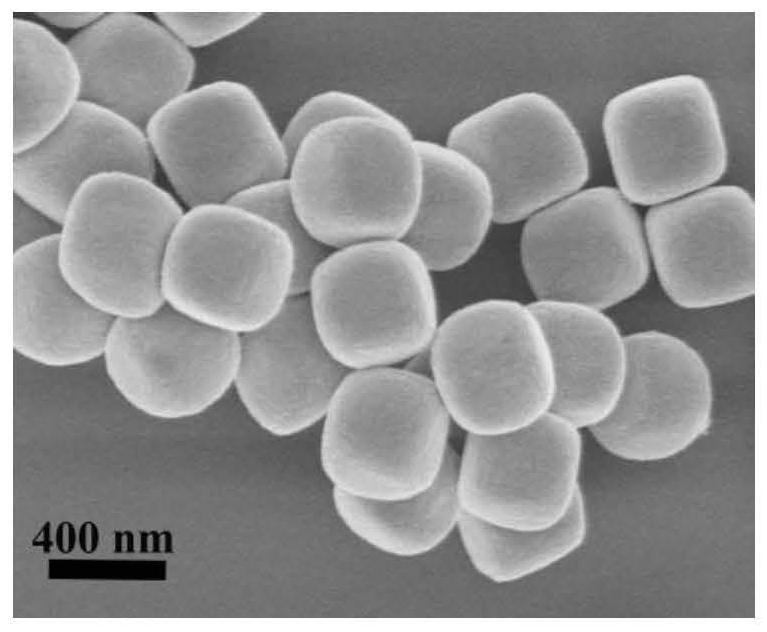

[0073] Fe with a particle size of 500nm 2 o 3 Nanocubes as templates (morphology such as Figure 1a shown), using the in-situ coating method on Fe 2 o 3 The surface of the nanocube is uniformly coated with a layer of polydopamine polymer, and sintered at high temperature under an argon atmosphere to obtain carbon-coated iron tetroxide (Fe...

Embodiment 2

[0086] This embodiment provides a lithium-sulfur battery positive pole piece and a lithium-sulfur battery. The positive electrode material of the lithium-sulfur battery positive pole piece is the sulfur positive electrode material S / Fe described in Example 1. 2 N@C, the positive pole piece of the lithium-sulfur battery is the positive pole piece of the lithium-sulfur battery.

[0087] The characterization results of the lithium-sulfur battery described in this example are as follows Figure 4a , Figure 4b , Figure 4c , Figure 4d , Figure 5a , Figure 5b shown.

[0088] The specific preparation method is as follows:

[0089] (1) Preparation of positive pole piece. Weigh the sulfur cathode material S / Fe according to the mass ratio of 80:12:8 2 N@C, superconducting carbon, and binder LA133 were placed in a high-energy ball milling tank. According to the ratio of LA133 / deionized water with a mass ratio of 1:20, deionized water was weighed and added to the high-energy b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com