Novel forming process for commutator segments of commutator

A molding process and commutator segment technology, which is applied in the field of new molding technology of commutator segment, can solve the problem of poor stability of composite structure of commutator segment, complex structure of commutator segment, unsatisfactory use effect, etc. problems, to avoid loosening, improve safety and efficiency, and facilitate processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

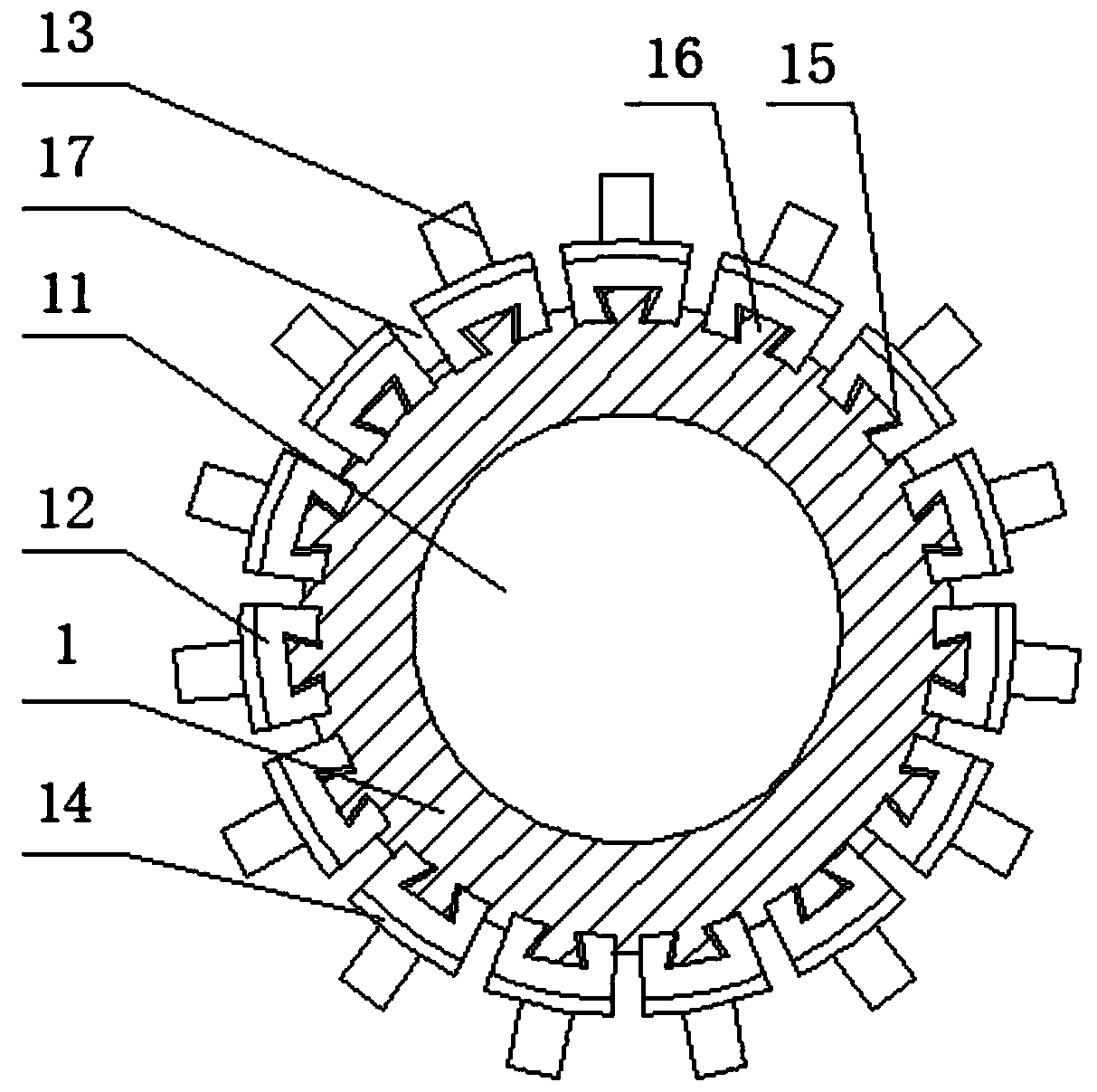

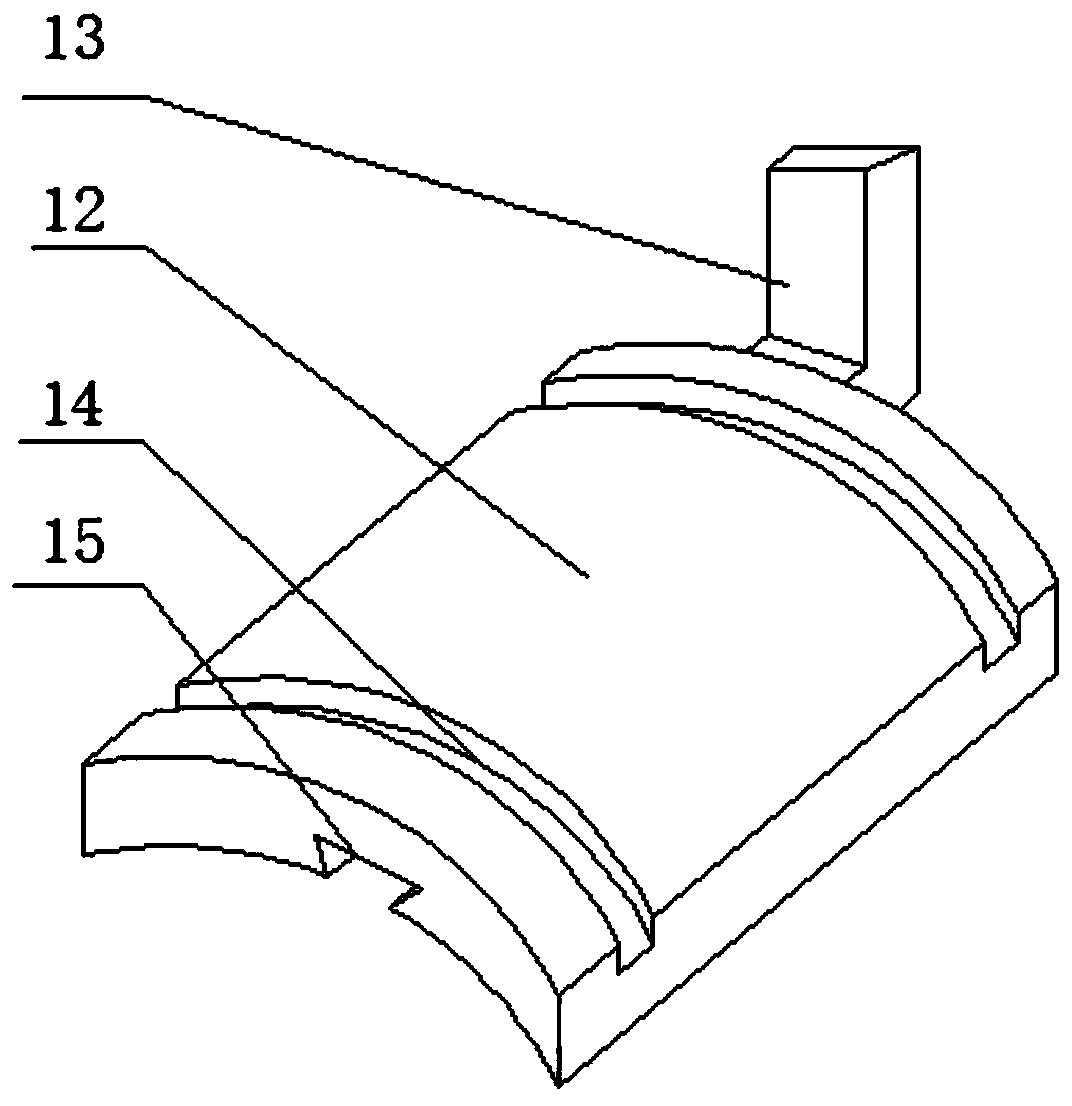

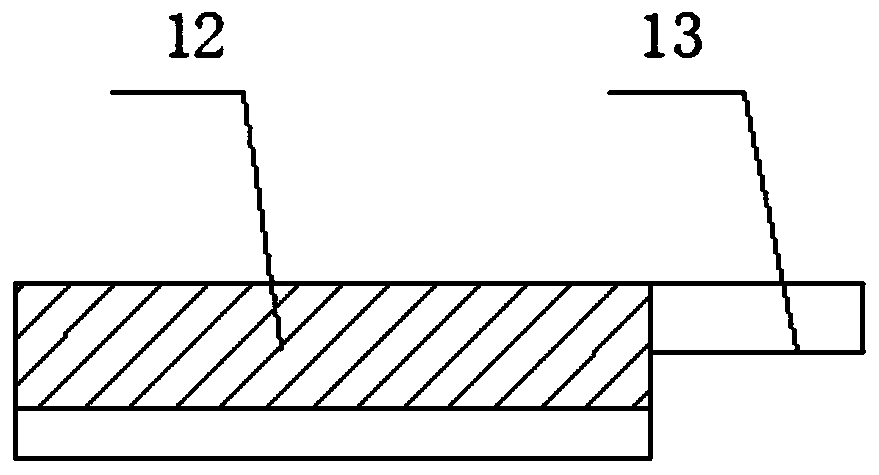

[0032] A new molding process for the commutator segment of a commutator, including a bakelite base 1, the inside of which is provided with a hollow cylinder 11, and the outer surface of the bakelite base 1 is fixedly inlaid with commutation Slice 12, the rear end of the commutator piece 12 is fixedly connected with a right-angle head 13, and both sides of the outer surface of the commutator piece 12 are provided with arc-shaped clip grooves 14, and a plurality of arc-shaped clip grooves 14 It can be combined into an annular groove, which is conducive to the use of wire clamps, which will not cause installation and use interference to the outside, and at the same time can ensure the stability of the connection structure of the commutator piece 12, which is beneficial to production, processing and use. A long dovetail groove 15 is provided in the middle of the inner surface of the sheet 14, and a long dovetail strip 16 is provided on the outer surface of the bakelite base 1, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com