Thin-tube laser beam quality self-compensation method and device

A laser beam quality and self-compensation technology, which is applied to laser components, lasers, phonon exciters, etc., can solve problems such as limited ability to improve beam quality and complex systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It must be pointed out that the described embodiments are only used to further describe the present invention, and do not mean any limitation to the protection scope of the present invention.

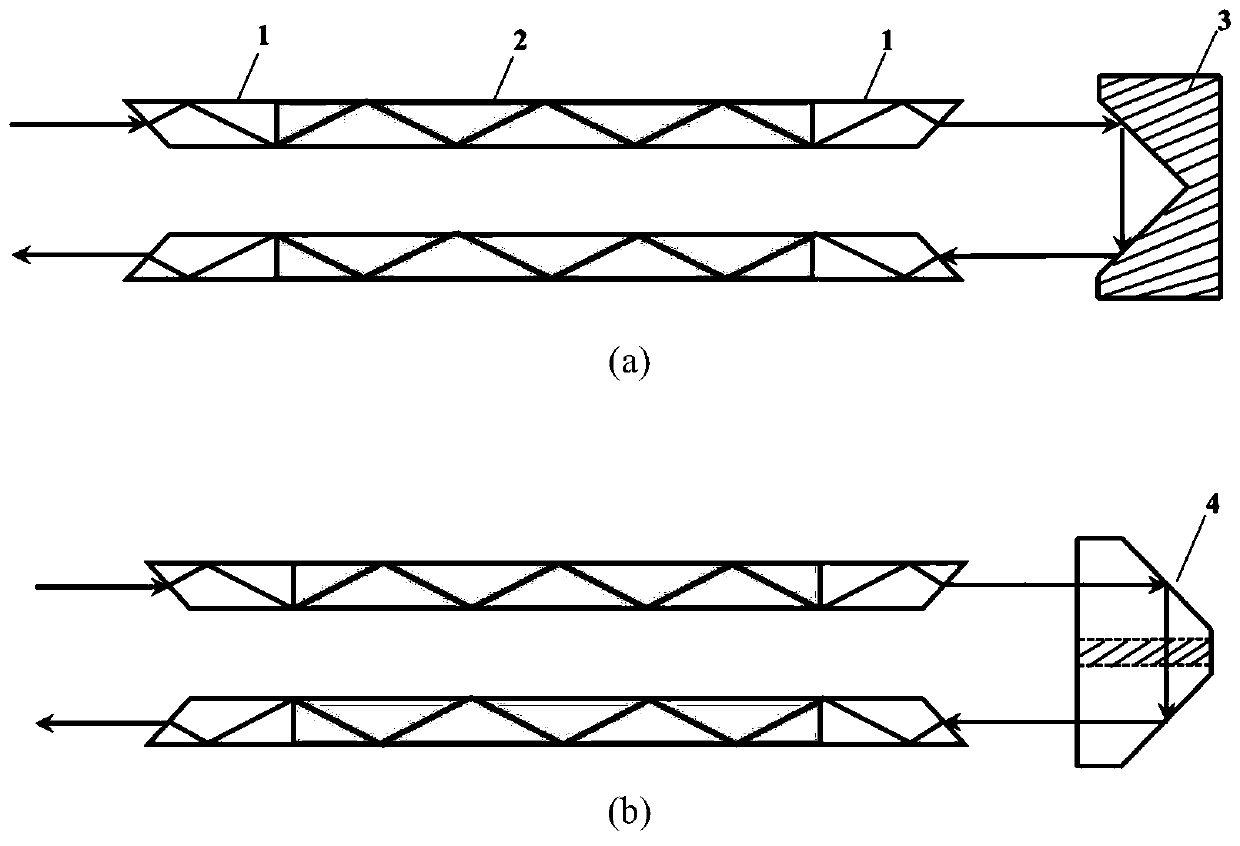

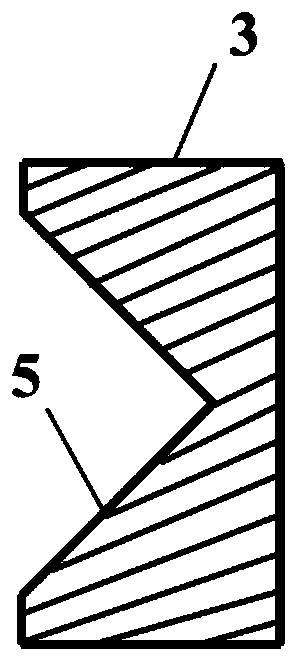

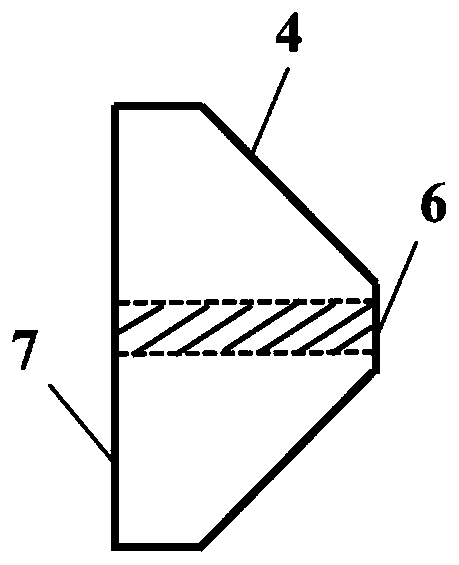

[0018] A thin-tube laser beam quality self-compensation method and device described in the present invention, the optical path for realizing the self-compensation method is as follows figure 1 shown. Including zigzag optical path thin tube laser device: 1 non-doped end cap, 2 doped thin tube, also includes zigzag optical path thin tube solid-state laser device Beam quality compensation device: 3 right-angle inner cone mirrors or 4 total reflection right-angle Tapered devices. Among them, the reflective surface of the right-angle inner cone mirror is coated with a high-reflection film system, and the incident / exit end surface of the total reflect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com