Two-dimensional thermal temperature difference type wind speed sensor and ambient self-compensation method for same

A technology of wind speed sensor and thermal temperature difference, which is applied in the direction of measuring fluid speed, instrument, speed/acceleration/impact measurement by using thermal variables, which can solve the problem of low detection rate of thermal temperature difference wind speed sensor, and achieve the improvement of thermal response rate and lateral Fast conduction reduces and improves the effect of wind speed and direction detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

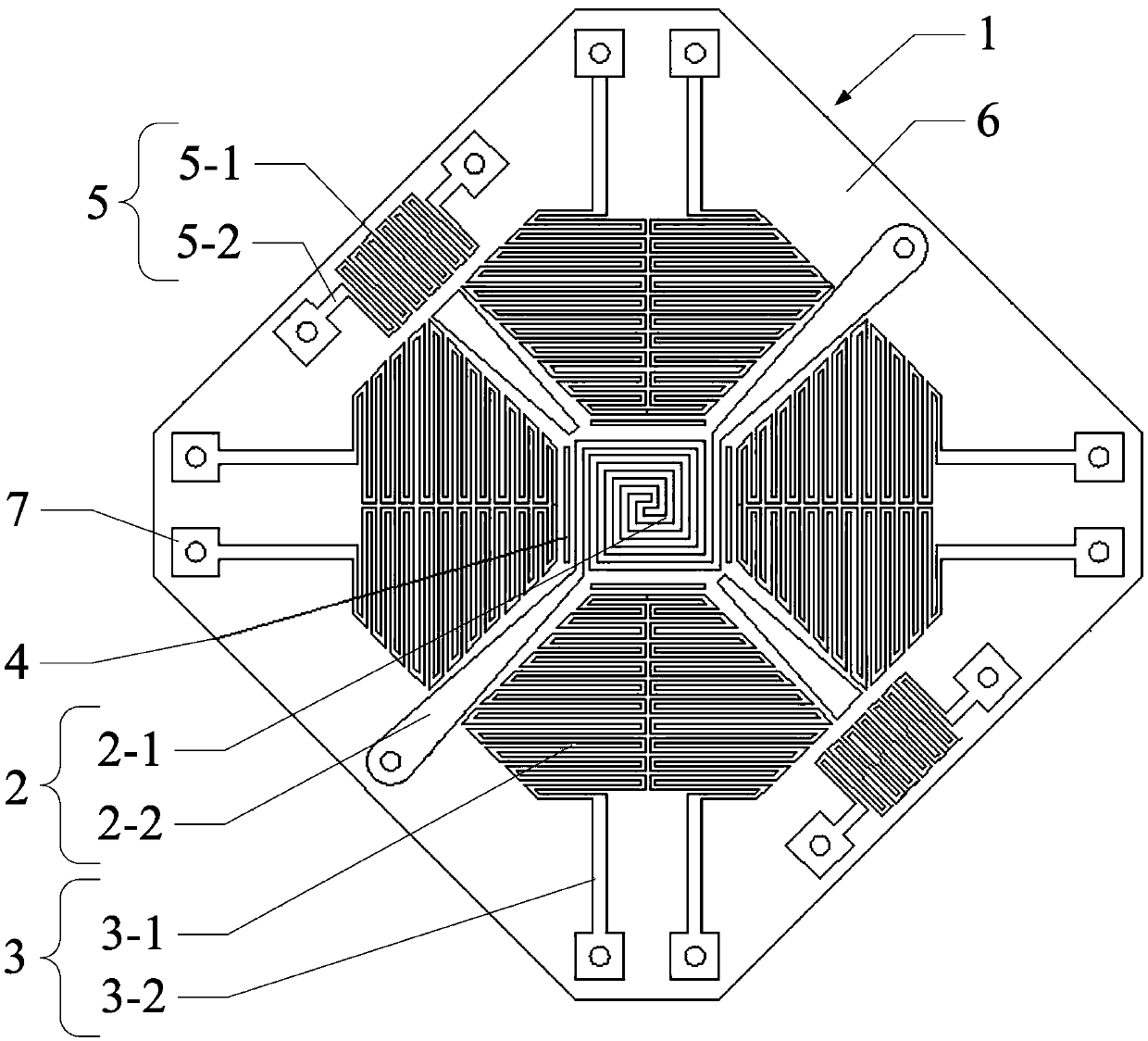

[0038] Embodiment: combine below Figure 1 to Figure 5 This embodiment will be described in detail.

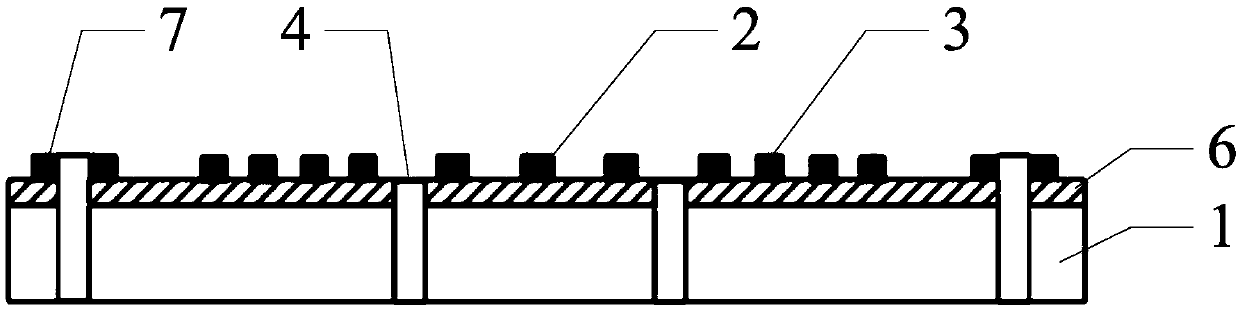

[0039] The two-dimensional thermal temperature difference wind speed sensor described in this embodiment includes a substrate 1, a heating electrode 2, four temperature detection electrodes 3, four thermal isolation grooves 4 and two ambient temperature self-compensation electrodes 5;

[0040] The substrate 1 is octagonal and made of low thermal conductivity material. On the top surface of the substrate 1 is laid a thermally conductive medium layer 6, heating electrodes 2, four temperature detection electrodes 3 and two ambient temperature self-compensation electrodes 5 are all arranged on the heat conduction medium layer 6;

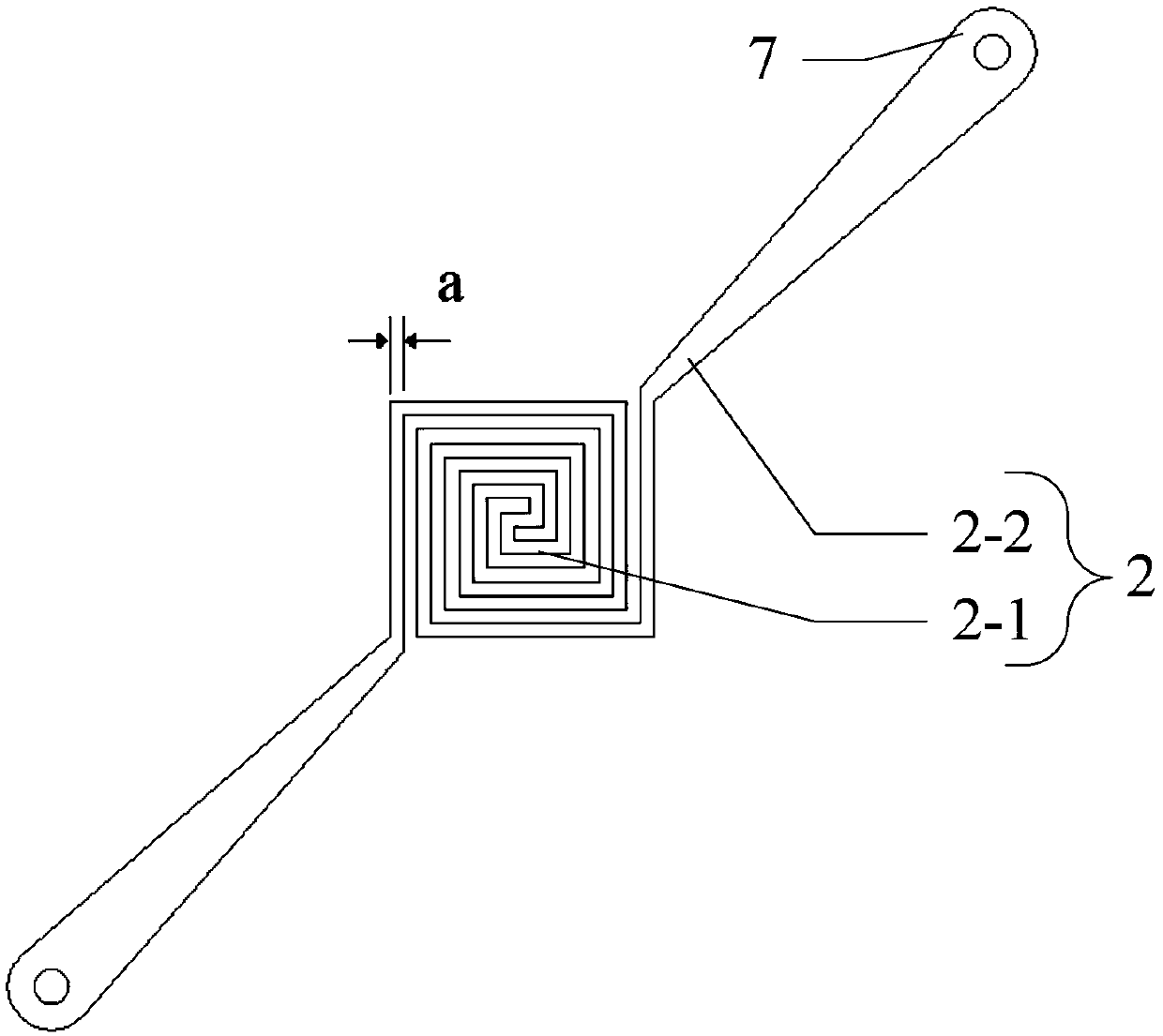

[0041] The heating electrode 2 includes a heating electrode body 2-1 and two lead-out electrodes 2-2. The heating electrode body 2-1 has a square coiled spiral structure, and is arranged at the center of the heat-conducting medium layer 6. The two lead-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com