Electrothermal phase change actuator based on graphene/nano-silver-emulsion film and its manufacturing method

A latex film and actuator technology, applied in the field of electrothermal phase change actuators, can solve the problems of small feedback force, high actuator drive voltage, uncontrollable feedback force, etc., and achieve controllable feedback force, low drive voltage, and easy start-up Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

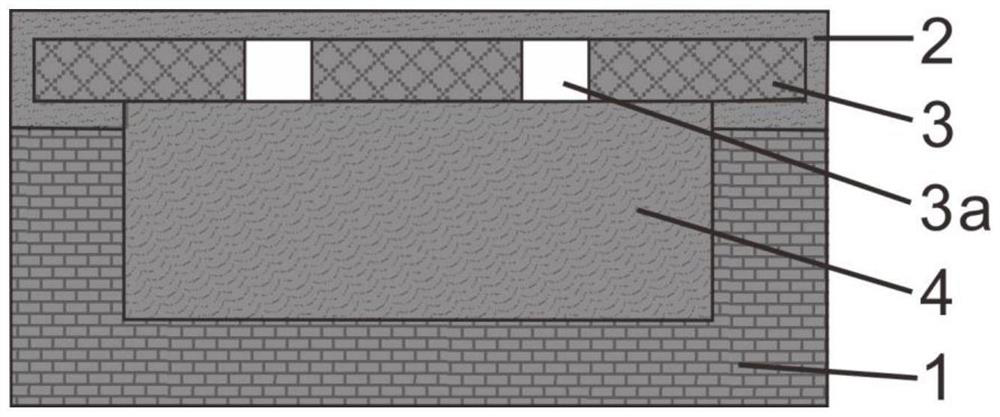

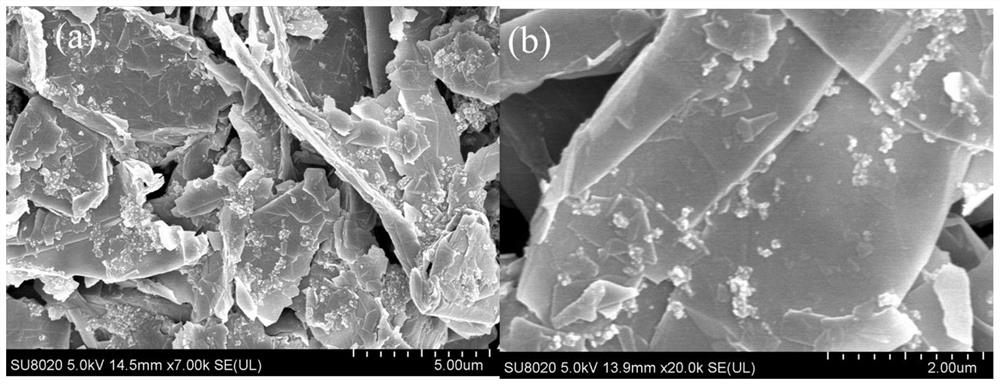

[0039] Such as figure 1 As shown, the electrothermal phase change actuator of this embodiment includes a thermal feedback substrate 1; the thermal feedback substrate is obtained by mixing graphene and nano-silver as conductive fillers with silicone rubber;

[0040] A groove is provided on the thermal feedback base 1, and a latex film cover is encapsulated on the upper surface of the thermal feedback base, so that the groove becomes a closed cavity storing the phase change material alcohol 4;

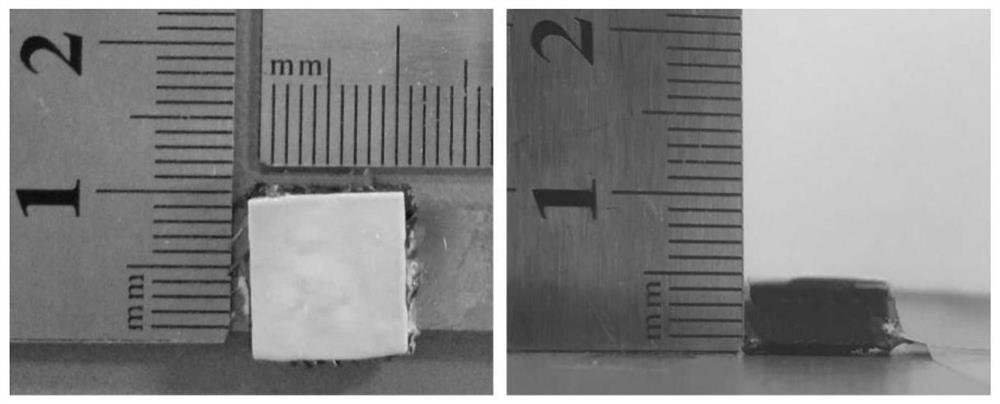

[0041] The latex film cover sheet is wrapped with a stretchable flexible latex film 2 outside a copper sheet 3 that is as large as the upper surface of the thermal feedback base; That is, the latex film only covers the whole of the upper surface of the copper sheet and a part of the lower surface, and the area of the lower surface corresponding to the groove is not covered), and several through holes 3a are provided, so that the latex film on the upper surface of the copper sheet and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com