Preparation method of polyethylene glycol/graphene shaped phase change material

A technology of polyethylene glycol and phase change materials, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of practical application inconvenience, and achieve the effect of being suitable for popularization, simple process and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

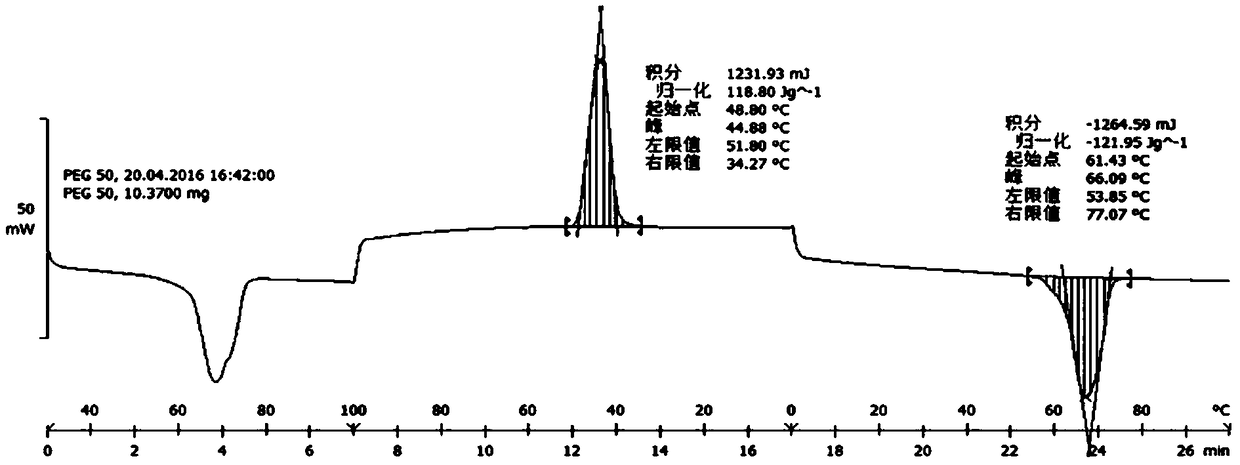

Embodiment 1

[0047] Take polyethylene glycol (PEG) and graphene respectively according to mass percentage; Wherein, the mass percentage of polyethylene glycol (PEG) is 97%, the mass percentage of graphene is 3%, and polyethylene glycol (PEG) PEG10000 is used;

[0048] Add the weighed polyethylene glycol (PEG) and graphene into the constant temperature electric heating mantle, and then raise the temperature of the constant temperature electric heating mantle to 65°C (preferably repeat three times), so that the polyethylene glycol (PEG) in the constant temperature electric heating mantle ) and graphene are completely melted, and polyethylene glycol / graphene melt is obtained after being cooled to room temperature;

[0049] Weigh the coupling agent KH650, and drop the weighed coupling agent KH650 into the polyethylene glycol / graphene melt, wherein the added mass of the coupling agent KH650 is 1 / 2 of the polyethylene glycol / graphene melt quality 0.03%, after being stirred evenly, the precursor...

Embodiment 2

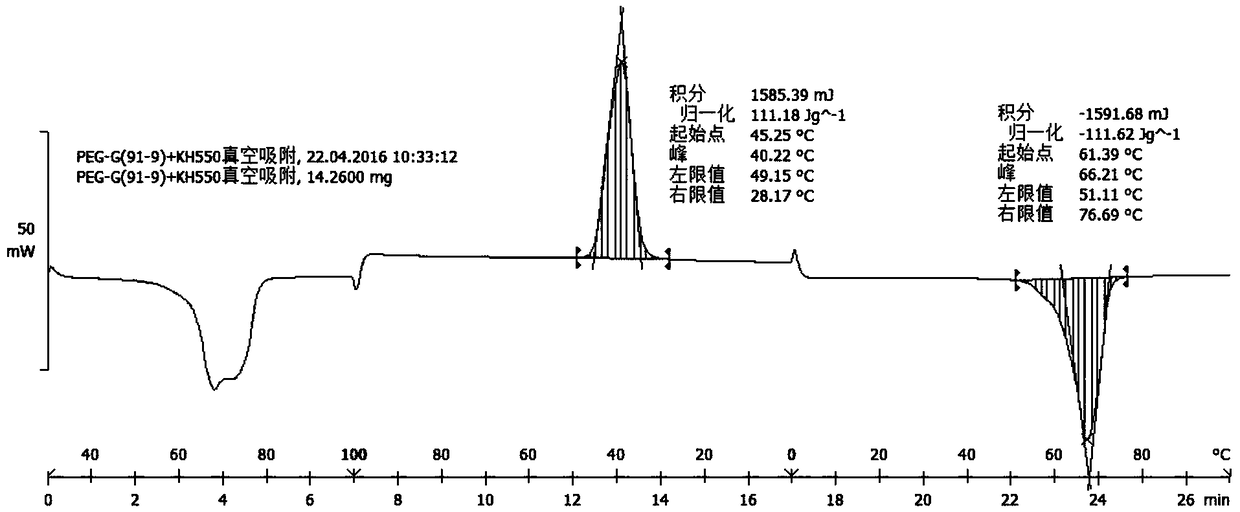

[0053] Take polyethylene glycol (PEG) and graphene respectively according to mass percentage; Wherein, the mass percentage of polyethylene glycol (PEG) is 91%, the mass percentage of graphene is 9%, and polyethylene glycol (PEG) PEG10000 is used;

[0054] Add the weighed polyethylene glycol (PEG) and graphene together into the constant temperature electric heating mantle, then raise the temperature of the constant temperature electric heating mantle to 70°C (preferably repeat three times), so that the polyethylene glycol (PEG) in the constant temperature electric heating mantle ) and graphene are completely melted, and polyethylene glycol / graphene melt is obtained after being cooled to room temperature;

[0055] Weigh the coupling agent KH650, and drop the weighed coupling agent KH650 into the polyethylene glycol / graphene melt, wherein the added mass of the coupling agent KH650 is 1 / 2 of the polyethylene glycol / graphene melt quality 0.04%, to obtain polyethylene glycol / graphe...

Embodiment 3

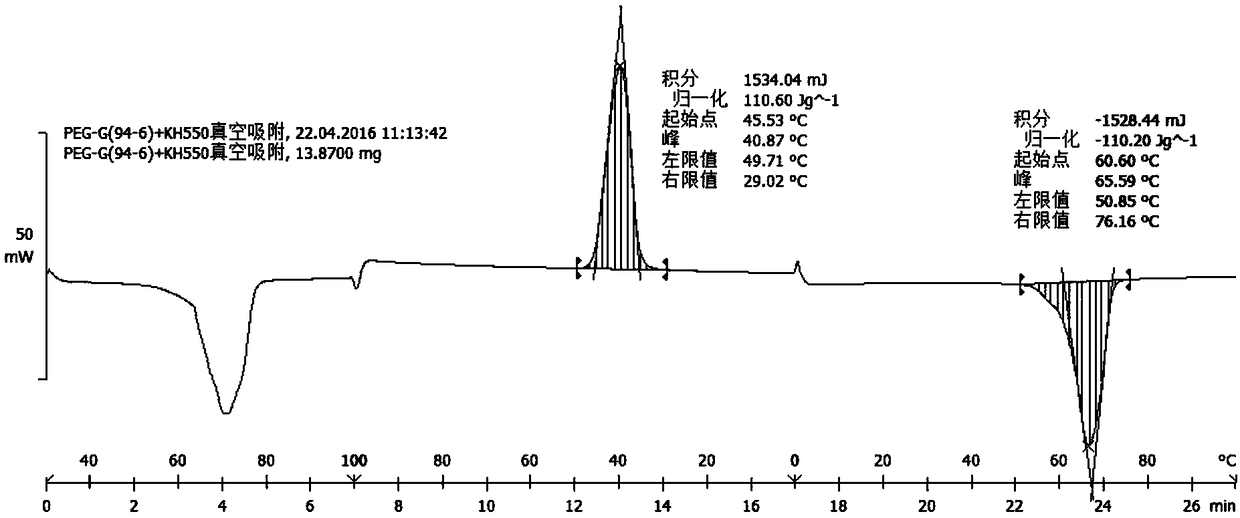

[0059] Take polyethylene glycol (PEG) and graphene respectively according to mass percentage; Wherein, the mass percentage of polyethylene glycol (PEG) is 96%, the mass percentage of graphene is 4%, and polyethylene glycol (PEG) PEG10000 is used;

[0060] Add the weighed polyethylene glycol (PEG) and graphene into the constant temperature electric heating mantle, then raise the temperature of the constant temperature electric heating mantle to 75°C (preferably repeat three times), so that the polyethylene glycol (PEG) in the constant temperature electric heating mantle ) and graphene are completely melted, and polyethylene glycol / graphene melt is obtained after being cooled to room temperature;

[0061] Weigh the coupling agent KH650, and drop the weighed coupling agent KH650 into the polyethylene glycol / graphene melt, wherein the added mass of the coupling agent KH650 is 1 / 2 of the polyethylene glycol / graphene melt quality 0.05%, to obtain polyethylene glycol / graphene stereo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com