Radiator-fan gravity heat pipe enhanced heat dissipation device for indoor heating

A gravity heat pipe and cooling device technology, applied in the field of energy saving, can solve the problems of slow heating rate, low heat dissipation efficiency, large thermal inertia, etc., and achieve the effects of fast start-up speed, improved heat dissipation efficiency, and increased heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

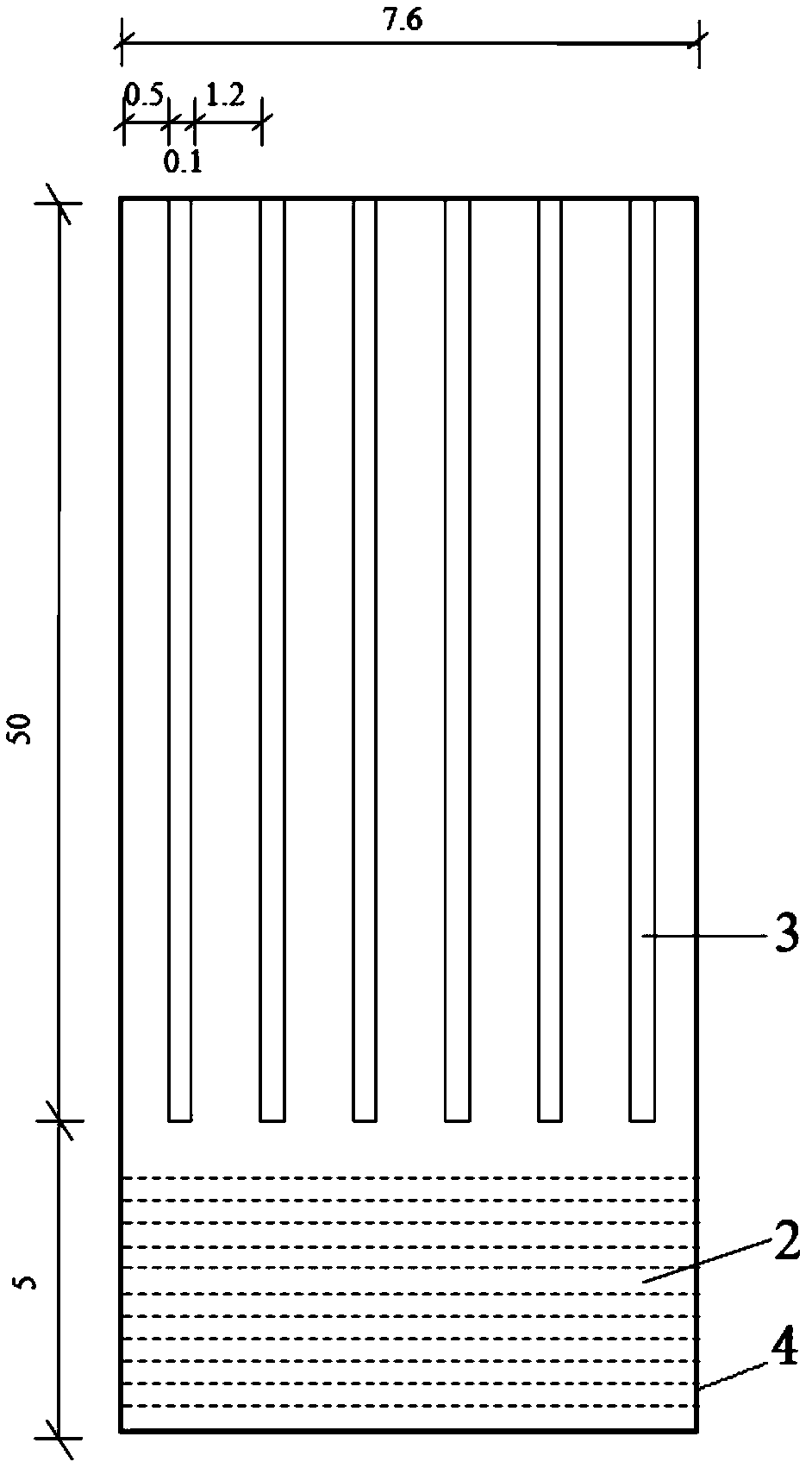

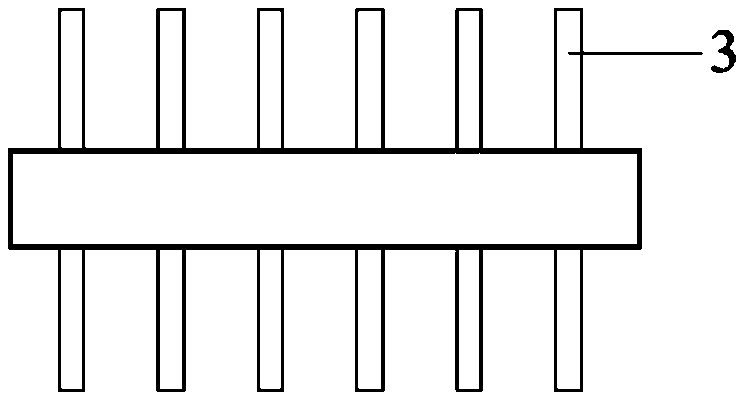

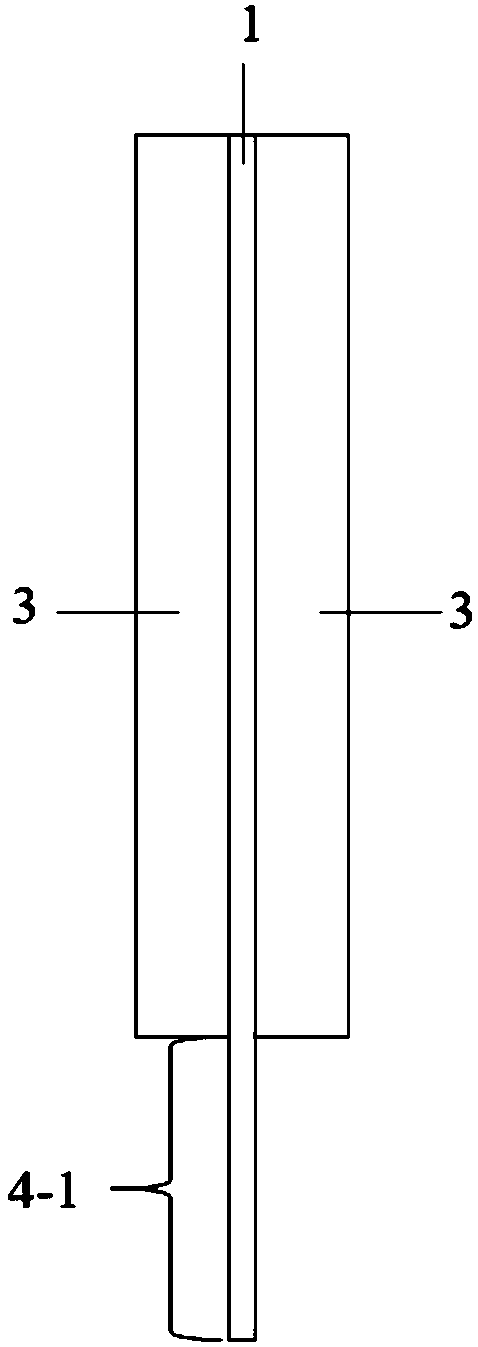

[0027] Such as figure 1 and figure 2 As shown, the invention provides a finned gravity heat pipe enhanced heat dissipation device for indoor heating, which includes a gravity heat pipe body 1 , a liquid phase change working medium 2 and rectangular straight fins 3 .

[0028] The gravity heat pipe body 1 is a long thin plate hollow structure made of high thermal conductivity materials such as aluminum or copper, filled with a small amount of low-boiling liquid phase-change working medium 2 such as acetone or water. A certain number of rectangular straight fins 3 with a certain interval are arranged on both sides of the gravity heat pipe body 1. The rectangular straight fins 3 are arranged parallel to the length direction of the gravity heat pipe body 1. Different rectangular straight fins 3 are arranged along the The pipe body 1 is evenly distributed in the width dir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com