Flat-plate solar collector plate core with whole-face convection function

A flat-panel solar energy and heat-collecting plate core technology, which is applied in the field of solar thermal utilization, can solve problems that do not conform to the principle of synergistic field optimization, large heat exchange temperature differences in heat exchange channels, and design process deviations, etc., to ensure relative uniformity, Improved heat transfer performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

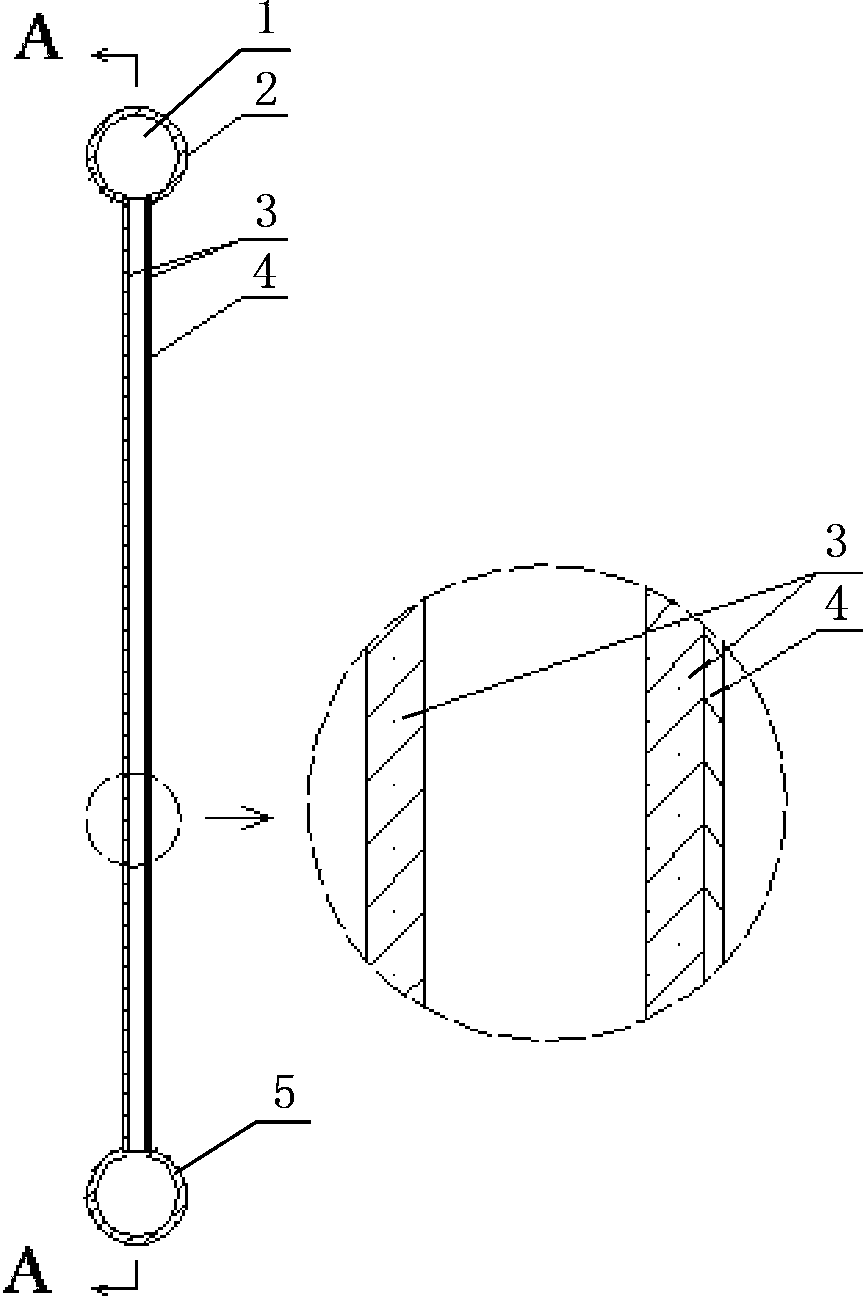

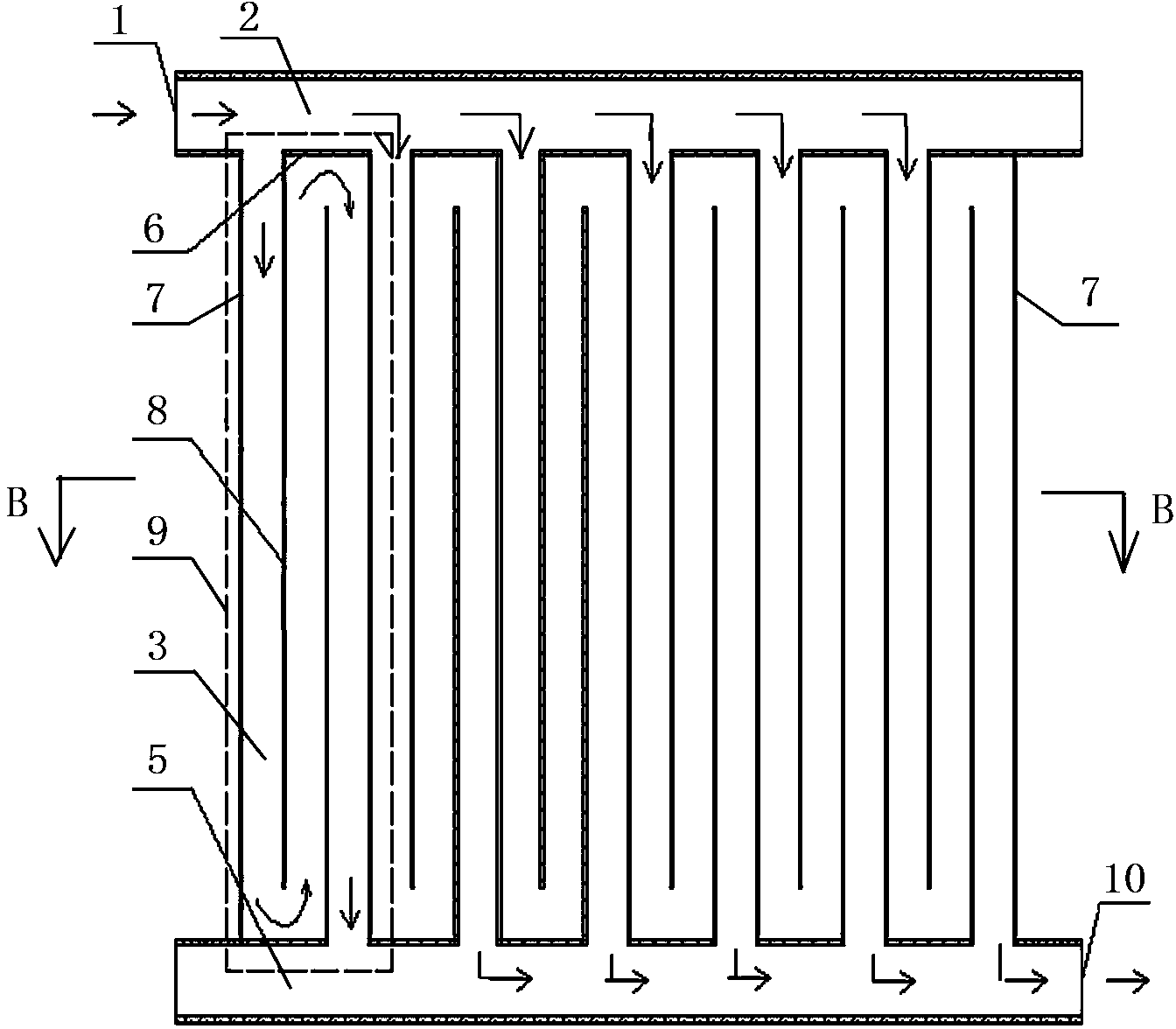

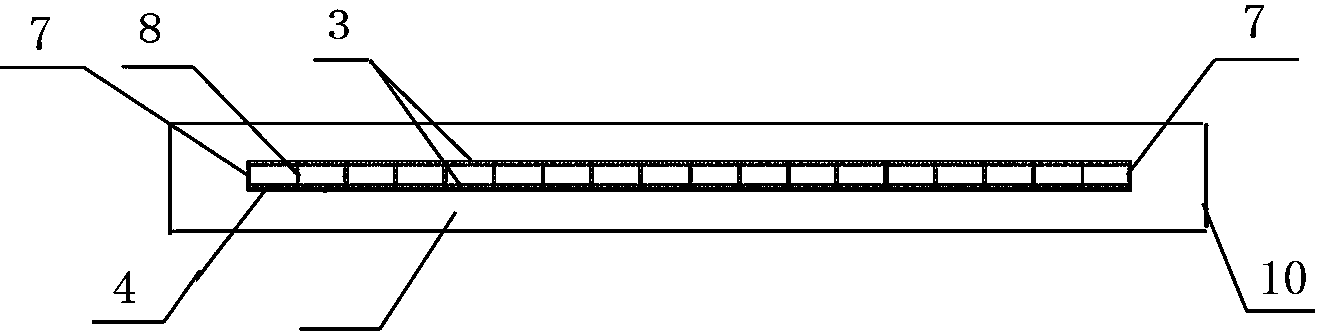

[0021] Such as figure 1 , 2 1. A kind of whole convective flat panel solar heat collector plate core of the present invention shown in 3, is made of following structure: two axially parallel circular fluid enters the main pipe 2 and the fluid exits the main pipe 5; The matching positions on the opposite sides of the inlet main pipe 2 and the fluid outlet main pipe 5 are provided with slots, and between the slotted positions are arranged axially parallel heat collector plates 3 and side sealing plates 7 at both ends. Closed cavity, the outer surfaces of the two heat collecting plates 3 are provided with a spectrally selective coating 4; the distance between the two heat collecting plates 3 is less than the fluid inlet and outlet dry pipes 2, 1 / 3 of the diameter. In the closed cavity, several vertical baffles 8 and horizontal baffles 6 are connected at staggered heights to form several S-shaped flow channels 9 . A fluid inlet 1 is provided at one end of the fluid inlet main p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com