Fast response phase change temperature control device

A temperature control device and fast-response technology, which can be applied in the direction of using electric mode for temperature control, auxiliary controller with auxiliary heating device, etc., which can solve the problems of low response rate, low module rate, high cost, etc. Heat transfer area, increase safety margin, and improve the effect of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

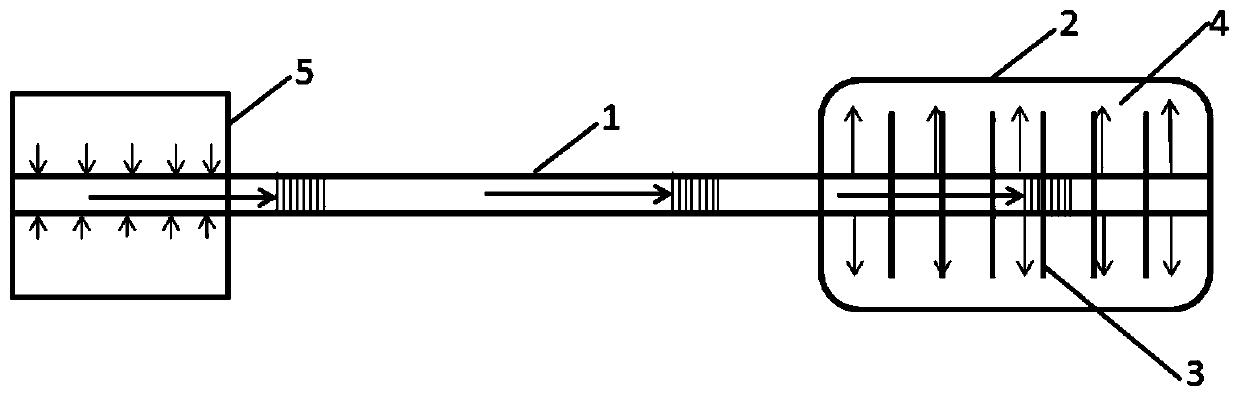

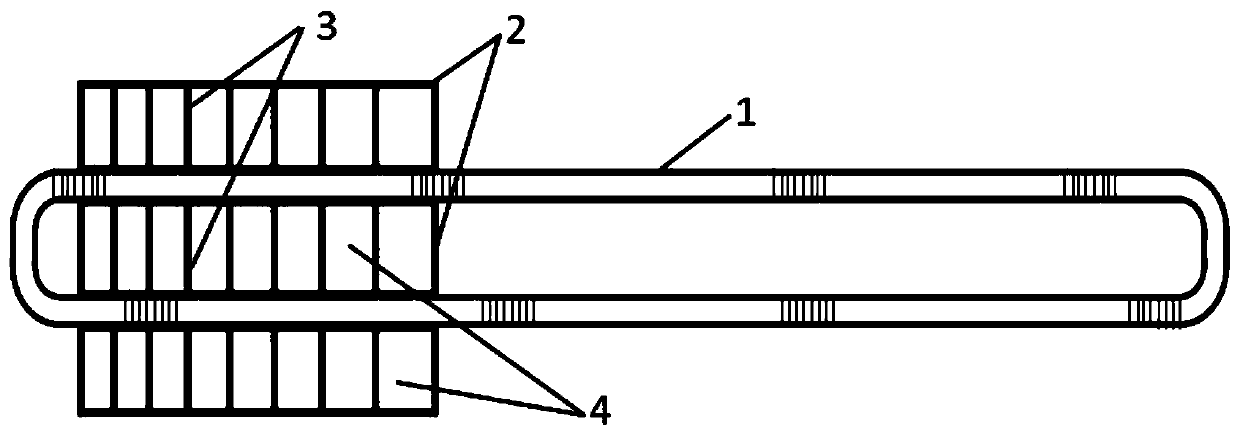

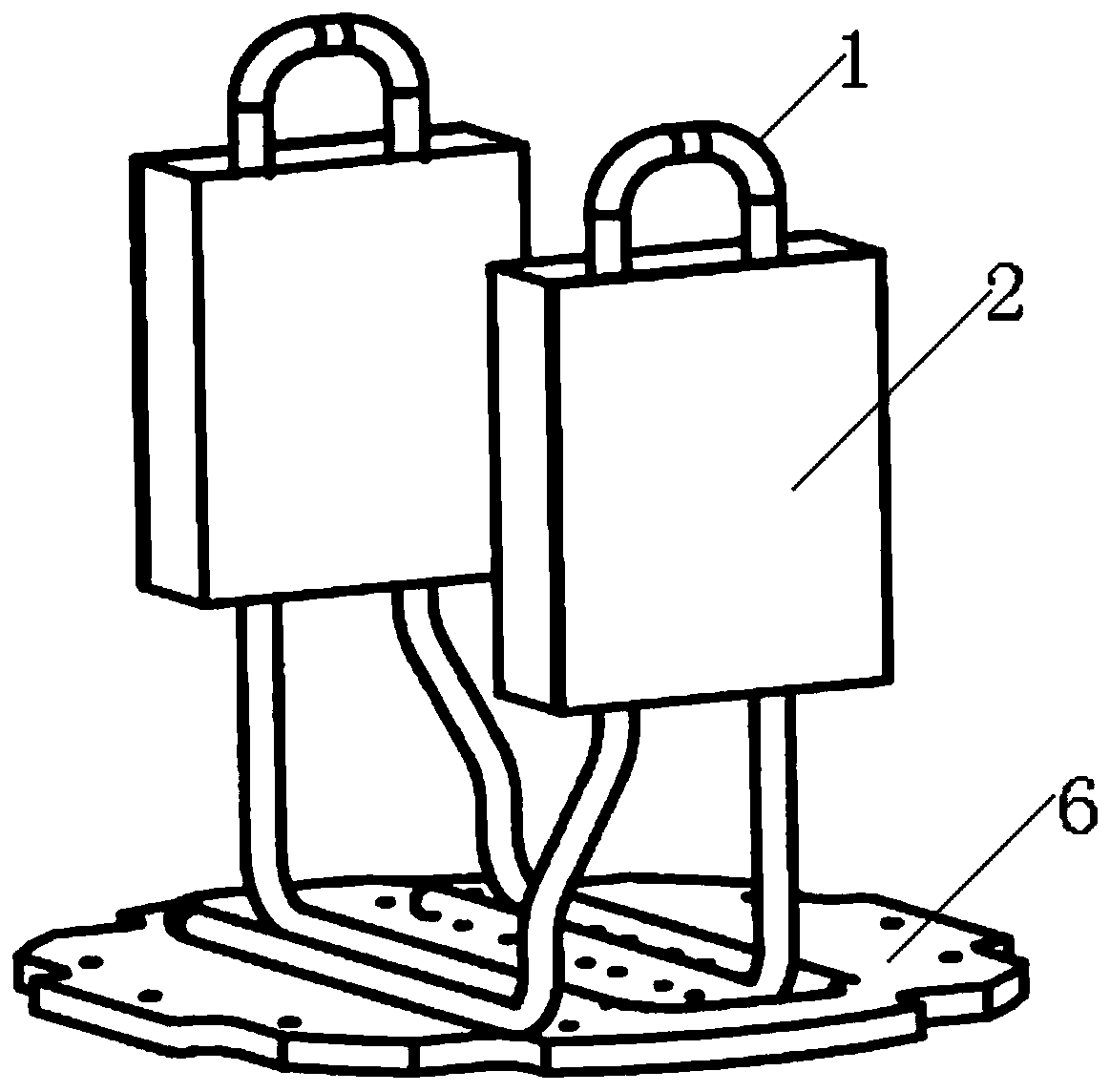

[0028] refer to figure 1 , figure 2 . In the embodiment described below, the fast-response phase change temperature control device includes: a pulsating heat pipe PHP1 that conducts heat transfer through the phase change of the internal liquid working fluid, and a metal energy storage cavity 2 filled with a high thermal conductivity phase change material 4 for improving Fin grid structure 3 with thermal response rate, high thermal conductivity phase change material 4 for storing heat.

[0029] When the temperature-controlled device / equipment 5 is working, the heat emitted by it is transferred to the hot end of the pulsating heat pipe PHP1, and the liquid medium filled in the hollow metal loop pipe undergoes a phase change, and the heat is brought to the cold end of the pulsating heat pipe PHP1, and transferred To the rib grid structure 3, it is absorbed by the high thermal conductivity phase change material 4 in the metal energy storage cavity 2 to prevent the temperature-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com