A non-rectangular surface heater based on metal nanowire film

A metal nanowire and heater technology, applied in ohmic resistance heating, heating element materials, ohmic resistance heating parts, etc., can solve the problems of no patent protection, few regular rectangular heating surfaces, etc. The effect of reducing power consumption and improving thermal response rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

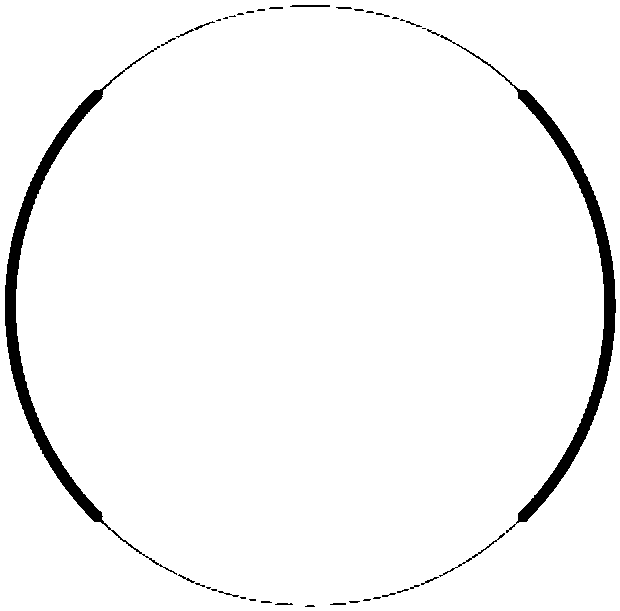

[0028] This embodiment provides a circular surface heater based on a silver nanowire transparent conductive film that can be used on the porthole of a spacecraft and a preparation method thereof. The steps of the preparation method are as follows:

[0029] (1) Substrate: A circular polyethylene terephthalate substrate with a thickness of 100 μm and a diameter of 20 cm was cut for use.

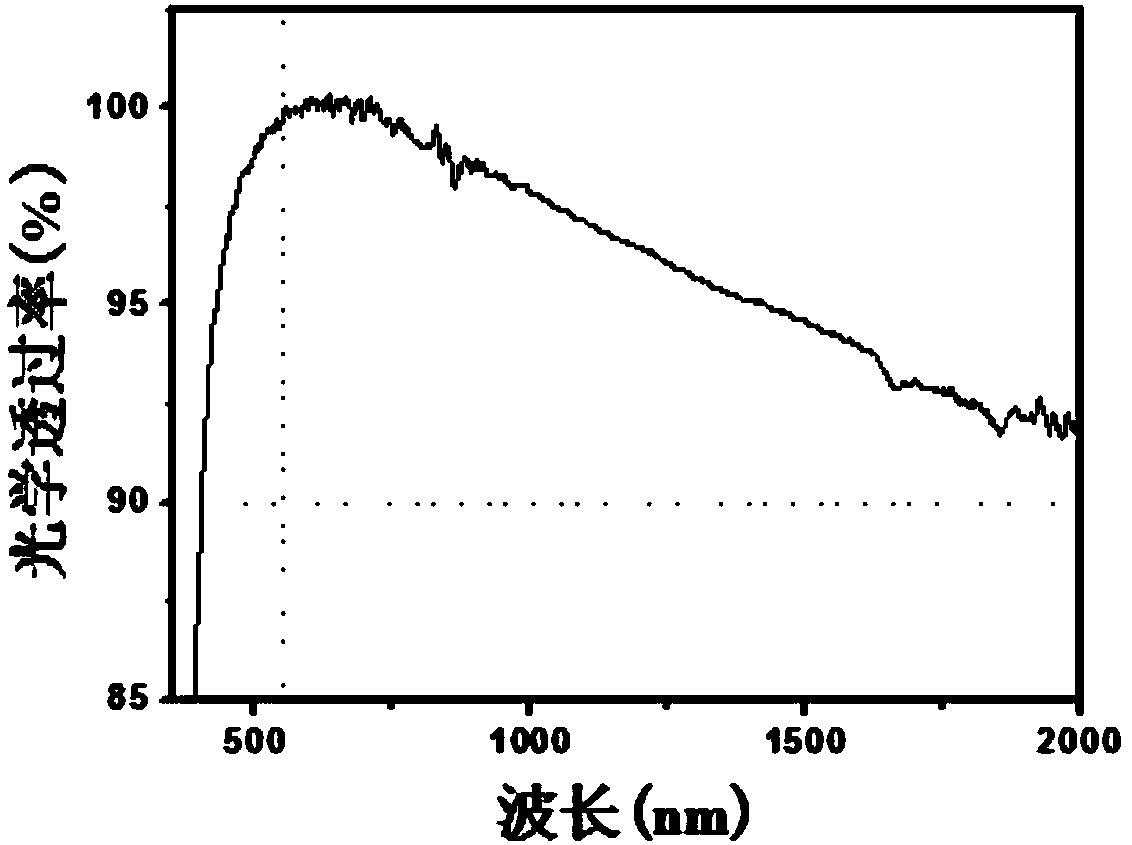

[0030] (2) Conductive functional film: On the substrate, use an automatic scraper coating device to apply an ink with a concentration of 1mg / mL prepared by silver nanowires with a diameter of 100nm and a length of 100μm, and scrape once to form a film, and then dry it in a drying oven at 60°C for 5 minutes .

[0031] (3) Performance adjustment layer: soak the dried film in 5wt% tin chloride aqueous solution for 10 seconds, then soak it in deionized water for 10 seconds, and then dry it in a drying oven at 60° C. for 5 minutes.

[0032] (4) Conductive electrode: Use a mask to cover the film, le...

Embodiment 2

[0036] This embodiment provides a trapezoidal surface heater based on a silver nanowire transparent conductive film and a preparation method thereof that can be used on an automobile windshield. The steps are the same as in Example 1 except for the shape of the surface heater and the conductive electrodes, specifically :

[0037] The base is a trapezoid with a large arc surface whose upper and lower sides are 100cm, 135cm, and 60cm high, such as Figure 4 (a) shown. Using the largest inscribed rectangle of a trapezoid with a large arc surface, two schemes of conductive electrodes are obtained. Such as Figure 4 As shown in (b), based on the upper and lower sides of the rectangle with the largest area inscribed in the trapezoid, the edges of the trapezoid of the large arc surface enclosed by these two sides coincide with the upper and lower sides of the rectangle, that is, the rectangle’s The upper and lower sides are the distribution positions of a pair of metal electrodes....

Embodiment 3

[0039] This embodiment provides a rectangular heater with large rounded corners and a preparation method thereof that can be used on aircraft portholes and is based on a silver nanowire transparent conductive film. The steps are the same as in Embodiment 1 except for the shape of the surface heater and the design of the conductive electrodes, specifically :

[0040] The base is a 40cm×29cm rounded rectangle, and the length and width of the rounded corners span 10cm, such as Figure 5 (a) shown. Using the largest inscribed rectangle of a rounded rectangle, two schemes of conductive electrodes are obtained. Such as Figure 5 As shown in (b), based on the upper and lower sides of the largest area inscribed in the rounded rectangle, the edges of the rounded rectangle enclosed by these two sides coincide with the upper and lower sides of the rectangle, that is, the The upper and lower sides are the distribution positions of a pair of metal electrodes. Such as Figure 5 As show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com