Method for detecting flow rate using ultrasonic waves

A detection method and ultrasonic technology, applied in the measurement of flow/mass flow, ultrasonic/sonic/infrasonic, measurement devices, etc., can solve problems such as affecting measurement accuracy, and achieve self-compensation and avoid effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

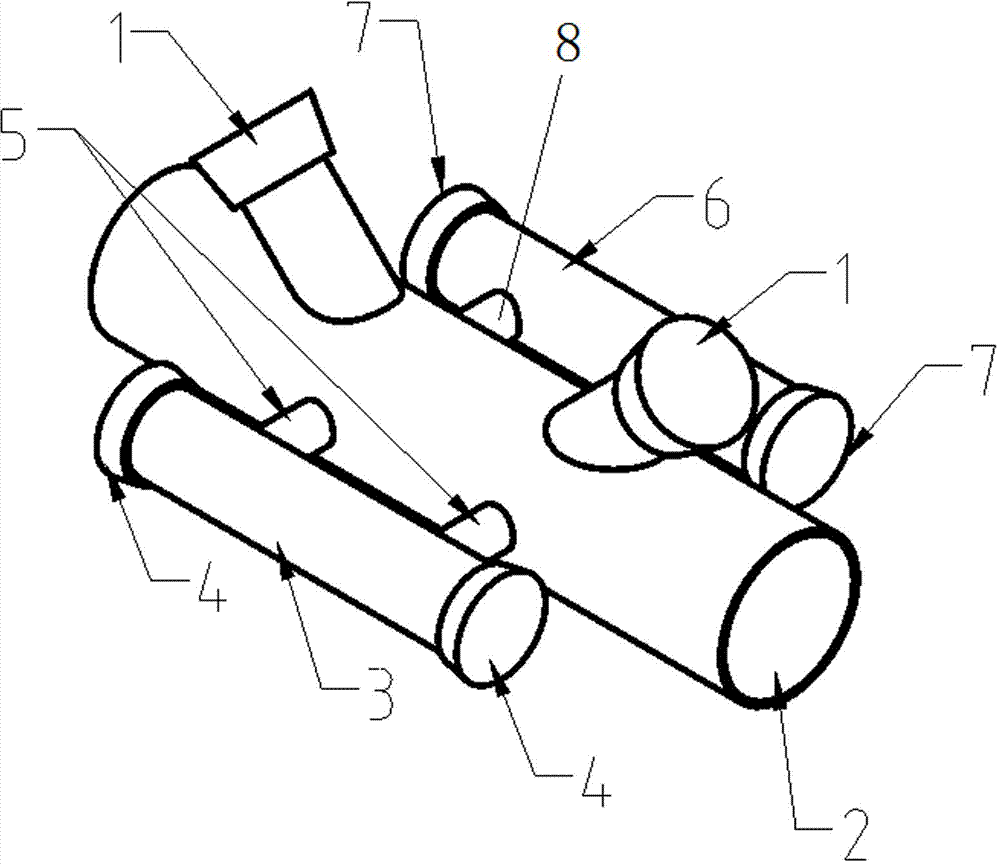

[0025] Utilize the embodiment of the detection method of ultrasonic detection flow, the detection method in this embodiment comprises the following steps:

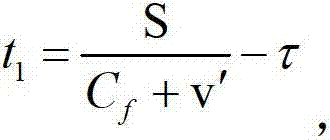

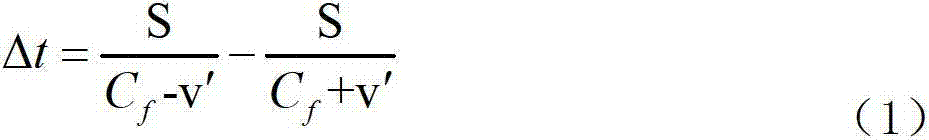

[0026] ① When the gas to be measured flows through the measuring tube, the ultrasonic transducer group arranged on the tube section of the measuring tube measures the downstream time t when the ultrasonic wave propagates downstream in the tube section 1and the countercurrent time t during countercurrent propagation 2 ; When the gas to be measured flows through the section of the measuring tube where the ultrasonic transducer group is arranged, it freely diffuses into the two static tubes connected with the measuring tube. The ultrasonic transducer used to measure the ultrasonic propagation velocity in the tube, according to the layout of the ultrasonic transducer on the static tube, the measured sound path of the ultrasonic wave propagating in the corresponding static tube is obtained, and the length of the two measured so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com