Control circuit for safety protection of filter press

A control circuit and safety protection technology, which is applied in the direction of emergency protection circuit devices, circuit devices, emergency protection devices with automatic disconnection, etc., can solve the problems of unreliable protection, enlargement, and the inability to guarantee the instant ejection of the filter plate, etc., to achieve operation Reliable, simple electrical principle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

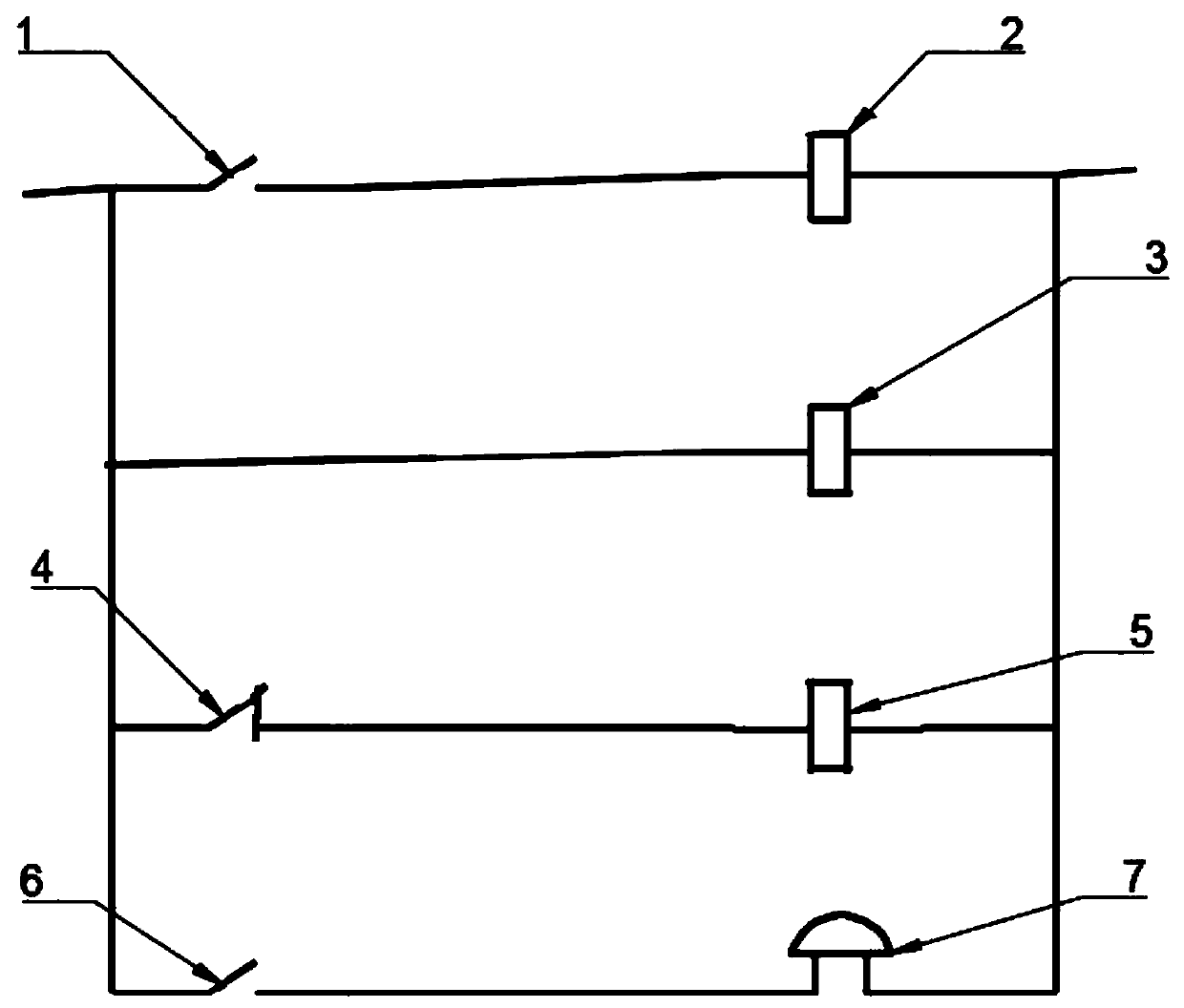

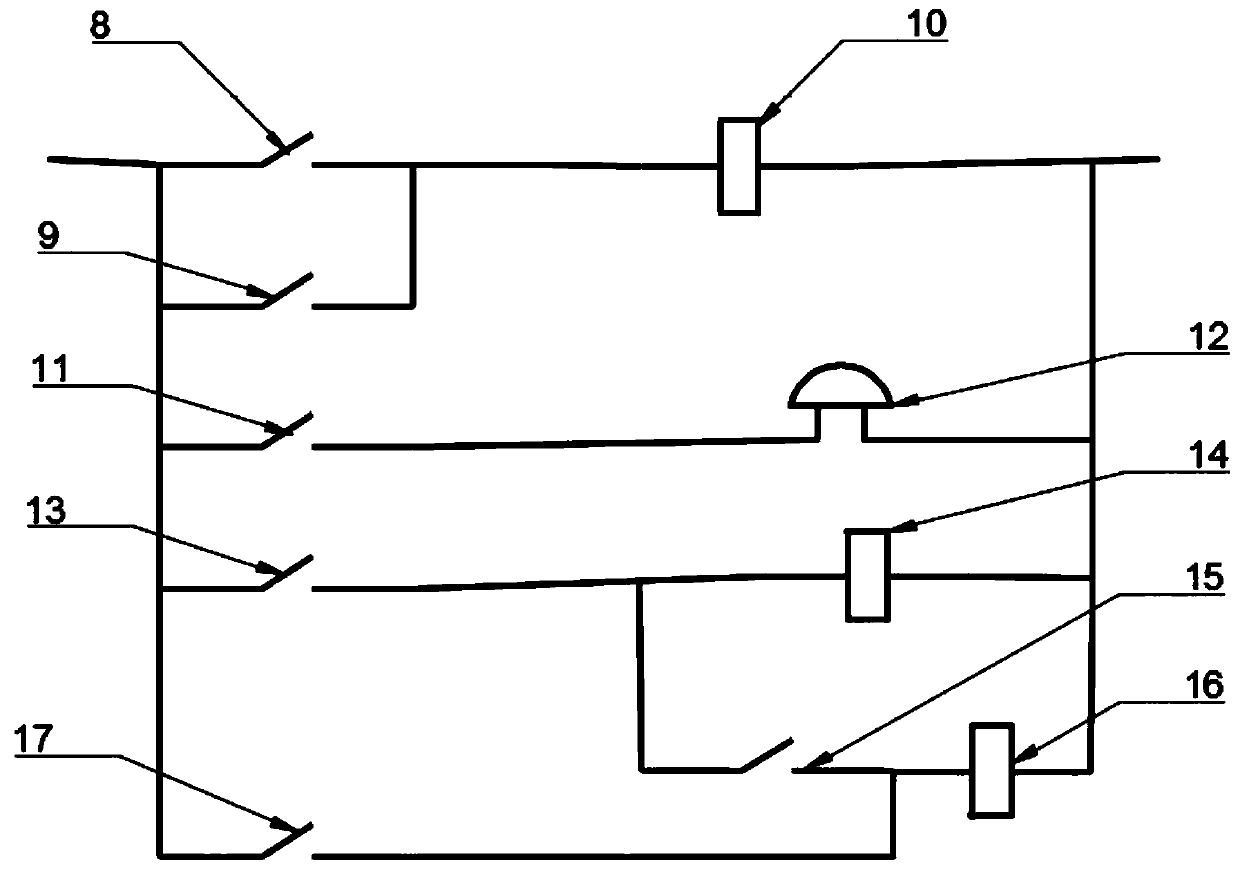

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0014] When the present invention is actually implemented, a control circuit for safety protection of a filter press includes several switch contacts, several relays, two buzzers, an infrared grating, an electric contact pressure gauge, a laser limiter, a rapid pressure discharge electromagnetic Valve, the control circuit is divided into two independent circuits, including control circuit a and control circuit b, but working at the same time, the switch contacts include normally open switch contacts and normally closed switch contacts according to functional requirements , time-delay closing switch contacts, the relay includes an intermediate relay, a time relay and an intermediate relay for controlling the pull plate, the infrared grating and the electric contact pressure gauge are designed based on the relay principle, and are embodied in the form of a relay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com