Engineering mechanical equipment for humidifying micro mist

A technology of construction machinery and equipment, which is applied in the field of humidification and micro-mist equipment, and can solve problems such as poor spray effect and clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

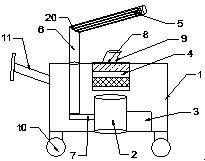

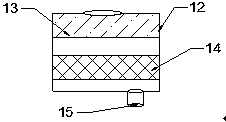

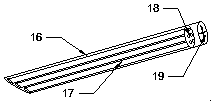

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

[0014] like Figure 1 to Figure 3 As shown, the present invention is a kind of engineering mechanical equipment for humidifying micro-mist, including equipment frame 1, booster pump 2, power supply assembly 3, filter core mechanism 4, high-pressure spray assembly 5 and filter connecting pipe 6, and the described equipment frame 1 is provided with a booster pump 2, one side surface of the booster pump 2 is fixedly connected with a power supply assembly 3, and the other side surface of the booster pump 2 is fixedly connected with a filter branch pipe 7, the said One end of the filter branch pipe 7 is fixedly connected to one end of the filter connection pipe 6, and the other end of the filter connection pipe 6 protrudes through the surface of the equipment frame 1 and is fixedly connected with a high-pressure spray assembly 5. The inside of the equipment frame 1 The upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com