A kind of superpressure aeration device and its application

An aeration device and high-pressure air chamber technology, applied in fertilization device, application, transportation and packaging, etc., can solve the problems of affecting aeration effect, short residence time, uneven dispersion, etc., to achieve good aeration effect, fog Good chemical effect and good fertilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

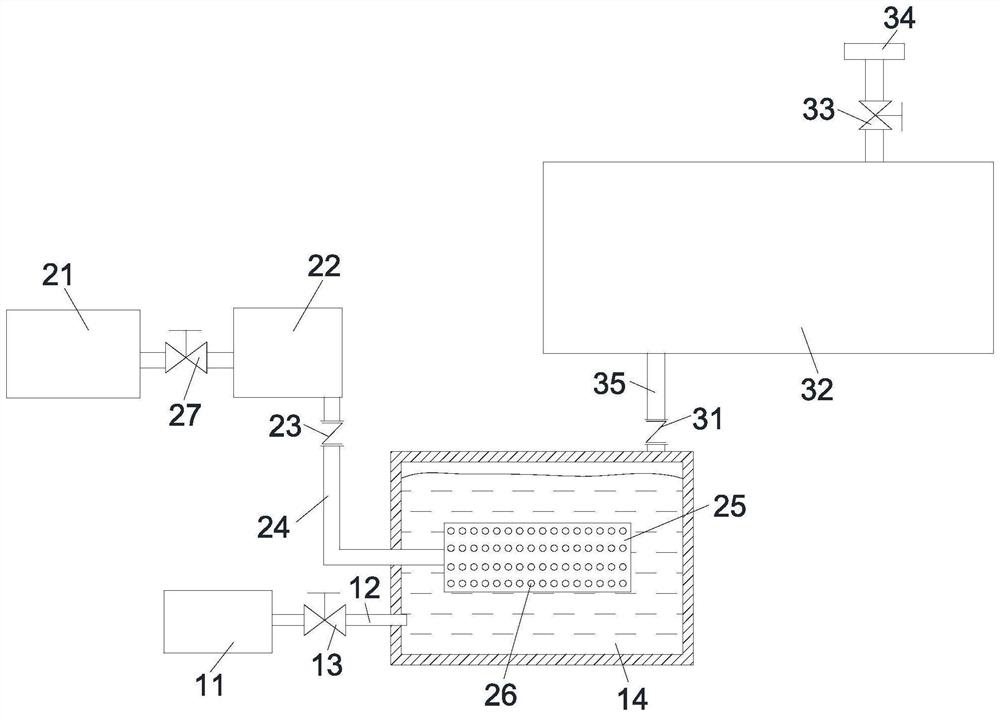

[0027] as attached figure 1 Shown: the present embodiment provides a kind of superpressure aeration device, comprises high-pressure liquid chamber 14, is located at the high-pressure air chamber 25 in the high-pressure liquid chamber 14, and the gas-liquid mixing chamber 32 that conducts with high-pressure liquid chamber 14, and with The nozzle 34 connected to the gas-liquid mixing chamber 32; the high-pressure gas chamber 25 is connected to a gas supply device, and the gas supply device is used to feed pressurized gas into the high-pressure gas chamber 25; the high-pressure liquid chamber 14 is connected to a liquid supply device, the liquid supply device is used to feed pressurized liquid into the high-pressure liquid chamber 14; the surface of the high-pressure gas chamber 25 is provided with a number of air holes 26 for feeding gas into the high-pressure liquid chamber 14; the high-pressure liquid chamber 14 and the gas-liquid mixing chamber 32 is provided with a throttlin...

Embodiment 2

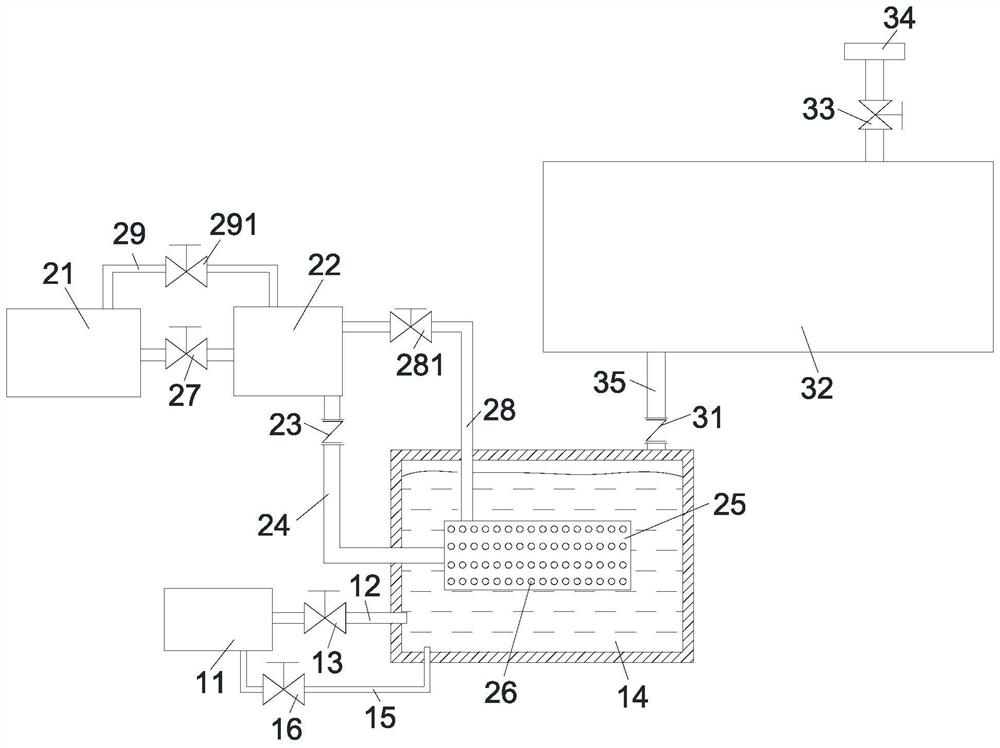

[0039] as attached figure 2 As shown, a first return air pipe 28 is provided between the high-pressure gas chamber 25 and the intermediate pressurized chamber 22 of this embodiment, and a first return air valve 281 is arranged on the first return air pipe 28; the intermediate pressurized chamber 22 and the gas A second return air pipe 29 is arranged between the pressurizing devices, and a second return air valve 291 is arranged on the second return air pipe 29 . In addition, a liquid return pipe 15 is provided between the high-pressure liquid chamber 14 and the liquid pressurizing device in this embodiment, and a liquid return valve 16 is provided on the liquid return pipe 15 .

[0040] In this embodiment, return passages are provided on the gas path and the liquid path, so that the overflow flow in the high-pressure area can be reused, and the pressure of the pressurized gas in the high-pressure gas chamber 25 and the pressure of the pressurized liquid in the high-pressure l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com