Anti-icing wind turbine blade, and method for preventing wind turbine blade from icing

A technology for wind power blades and anti-icing, which is applied to wind power generation, wind power engines consistent with the wind direction, wind power engines, etc., which can solve the inconvenience of preventing wind power blades and wind power blades from freezing, affect the power generation efficiency of wind power units, and fail to achieve technical effects and other problems, to achieve good anti-icing effect, convenient operation and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

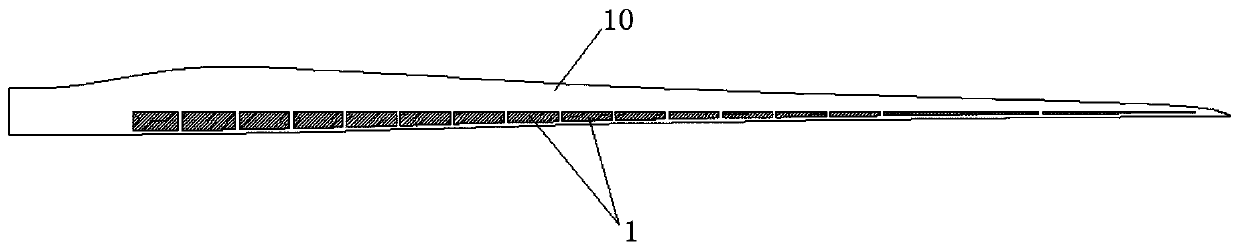

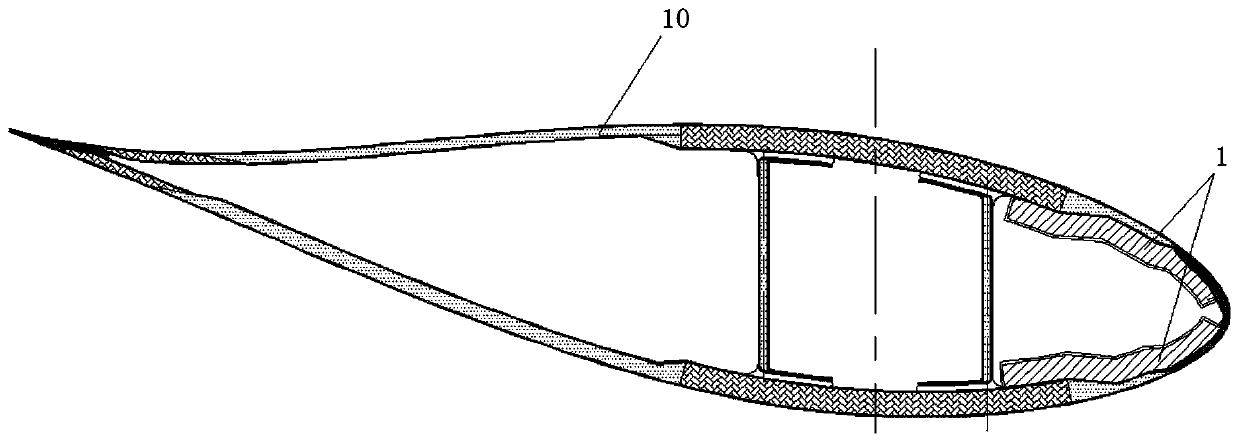

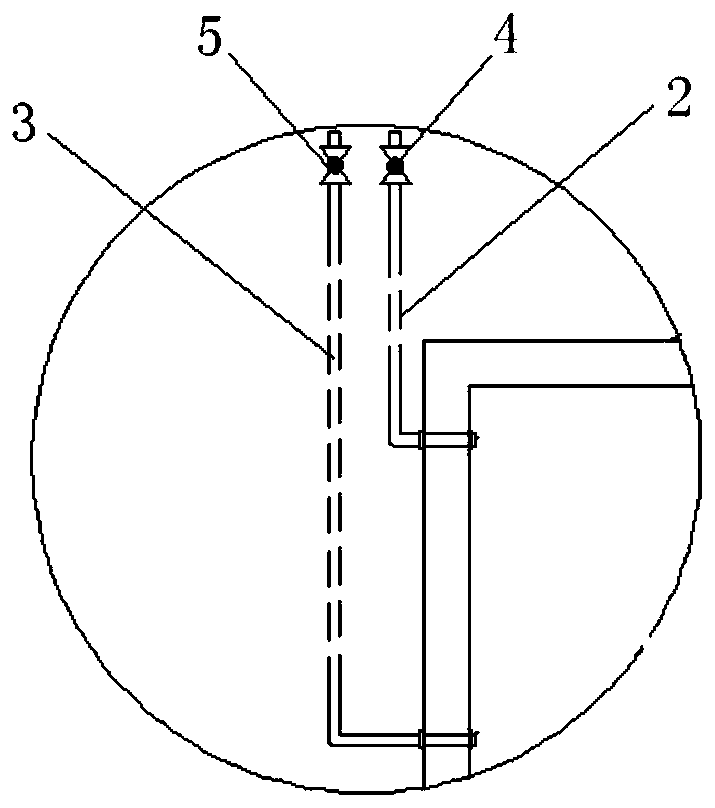

[0031] Refer to attached Figures 1 to 4 As shown, the specific structure of the anti-icing wind turbine blade in this embodiment is as follows. An anti-refrigeration body 1 is fixed on the inner surface of the wind power blade 10, two mutually independent pipelines 2, 3 are connected to the side wall of the anti-freezing body 1, and valves 4 are arranged on the two pipelines 2, 3 , 5, the two pipelines 2, 3 are used to inject or discharge high-density low-temperature-resistant liquid into the anti-refrigerator body 1 .

[0032] Specifically, the anti-freezing body 1 is fixedly bonded to the inner surface of the leading edge of the wind power blade 10 , and the outer shape of the anti-freezing body 1 matches the shape of the inner surface of the leading edge of the wind power blade 10 . That is, the anti-refrigeration body 1 is a box body customized according to the profile of the front edge of the blade inner cavity, and before the blade is molded, the customized box body is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com