Laser three-dimensional forming process detecting method and system and application thereof

A technology of laser three-dimensional forming and process inspection, which is applied in the direction of improving process efficiency, improving energy efficiency, and additive manufacturing, and can solve problems such as not being suitable for industrial production sites, difficult, high use costs, and high site requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

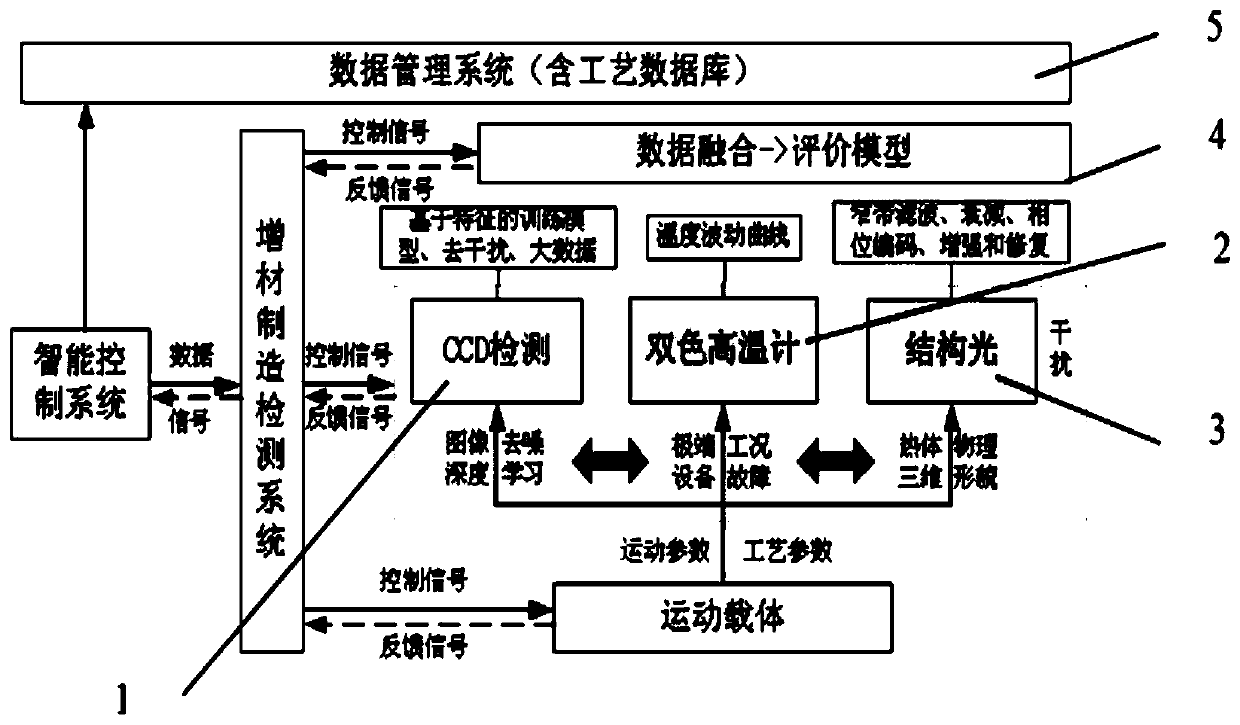

[0056] figure 1 It is a block diagram of the laser three-dimensional forming process detection system of the present invention, figure 2 It is a common defect diagram of laser stereoforming in the embodiment of the present invention.

[0057] A laser three-dimensional forming process detection method is characterized in that it comprises the following steps:

[0058] Step 1: Obtain the process parameter data of each equipment operating state through the equipment operating state detection device, and obtain the three-dimensional appearance of the part or the current layer or the molten pool area and its vicinity during the laser three-dimensional forming process through the structured light three-dimensional shape detection device 3 The surface topography data of the thermal component, the molten pool data in the image form of the molten pool shape, plume and splash during the laser three-dimensional forming process are obtained through the CCD molten pool detection device 1...

Embodiment 2

[0072] Such as figure 1 Shown:

[0073] A system for realizing a laser stereoforming process detection method,

[0074] Including multi-source heterogeneous information real-time monitoring device during forming process, data fusion evaluation model 4, data management system 5,

[0075]The multi-source heterogeneous information real-time monitoring device in the forming process includes: equipment operation state detection device, structured light three-dimensional shape detection device 3, CCD molten pool detection device 1, pyrometer temperature detection device 2; equipment operation state monitoring device: To obtain the process parameter data of each equipment operating state; the structured light three-dimensional shape detection device 3: used to obtain the thermal component surface of the three-dimensional shape of the part or the current layer or the molten pool area and its vicinity in the laser stereoforming process Shape data, structured light three-dimensional s...

Embodiment 3

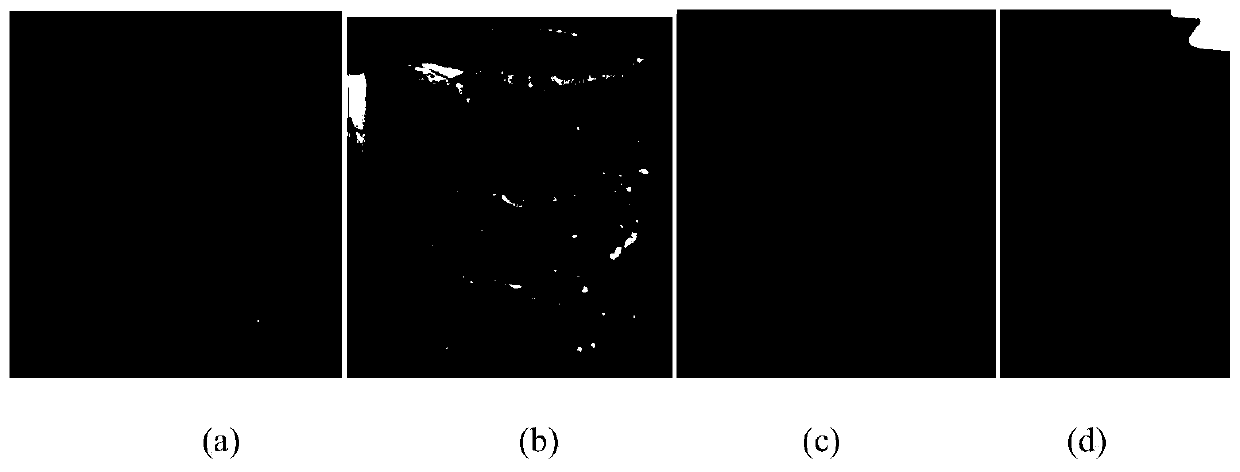

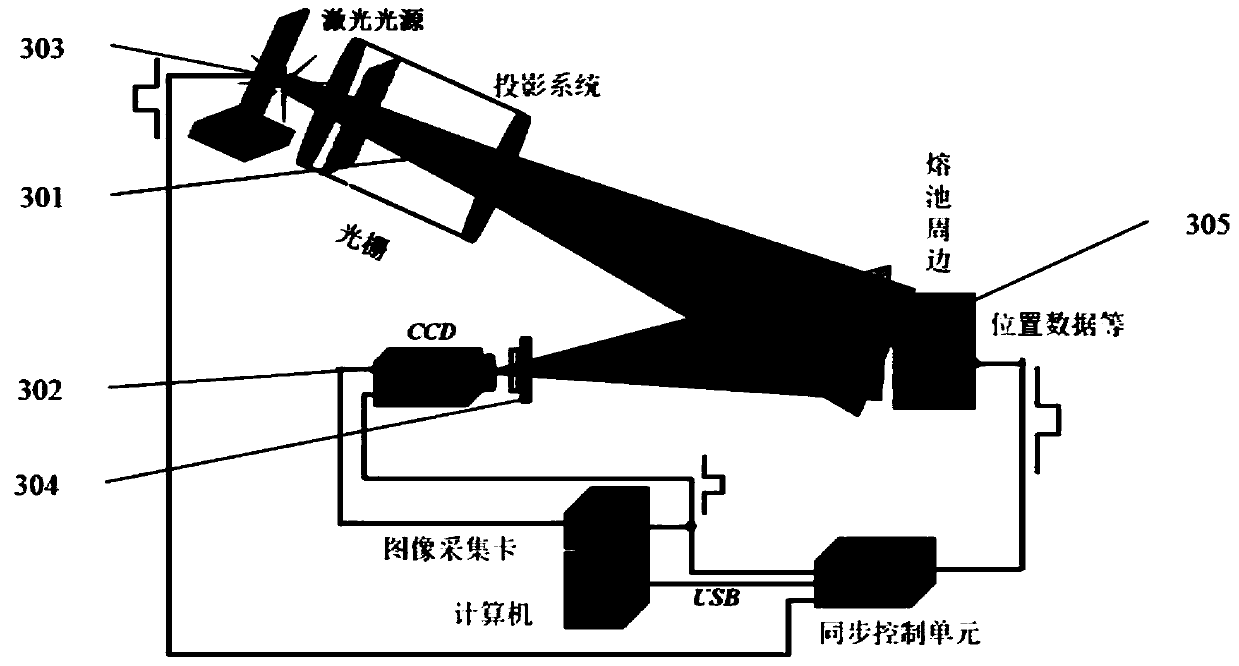

[0099] figure 2 is a common defect map of laser stereoforming in the embodiment of the present invention, image 3 It is a schematic diagram of the principle of measuring the molten pool and its vicinity by structured light in the present invention.

[0100] On the basis of Example 2, the structured light three-dimensional shape detection device 3 can figure 2 The topographical defects shown enable measurement in a laser environment or on the surface of a hot object. For an example of a measurement principle, see image 3 shown. The structured light three-dimensional shape detection device 3 is to perform the three-dimensional shape of the grating projection in the state of laser light emission during the laser three-dimensional forming process or when the forming object is in a hot state and high temperature state or when the measured area is a mixture of solid and liquid states Imaging; the wavelength of the light source required for its projection is determined accord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com