Two-arm mechanical hand mechanism capable of feeding parts one by one

A technology of manipulators and parts, which is applied in the field of dual-arm manipulator mechanisms, can solve the problems of hidden dangers of personnel safety accidents, reduce enterprise productivity, and large labor load, and achieve the effect of avoiding waiting time and compact processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

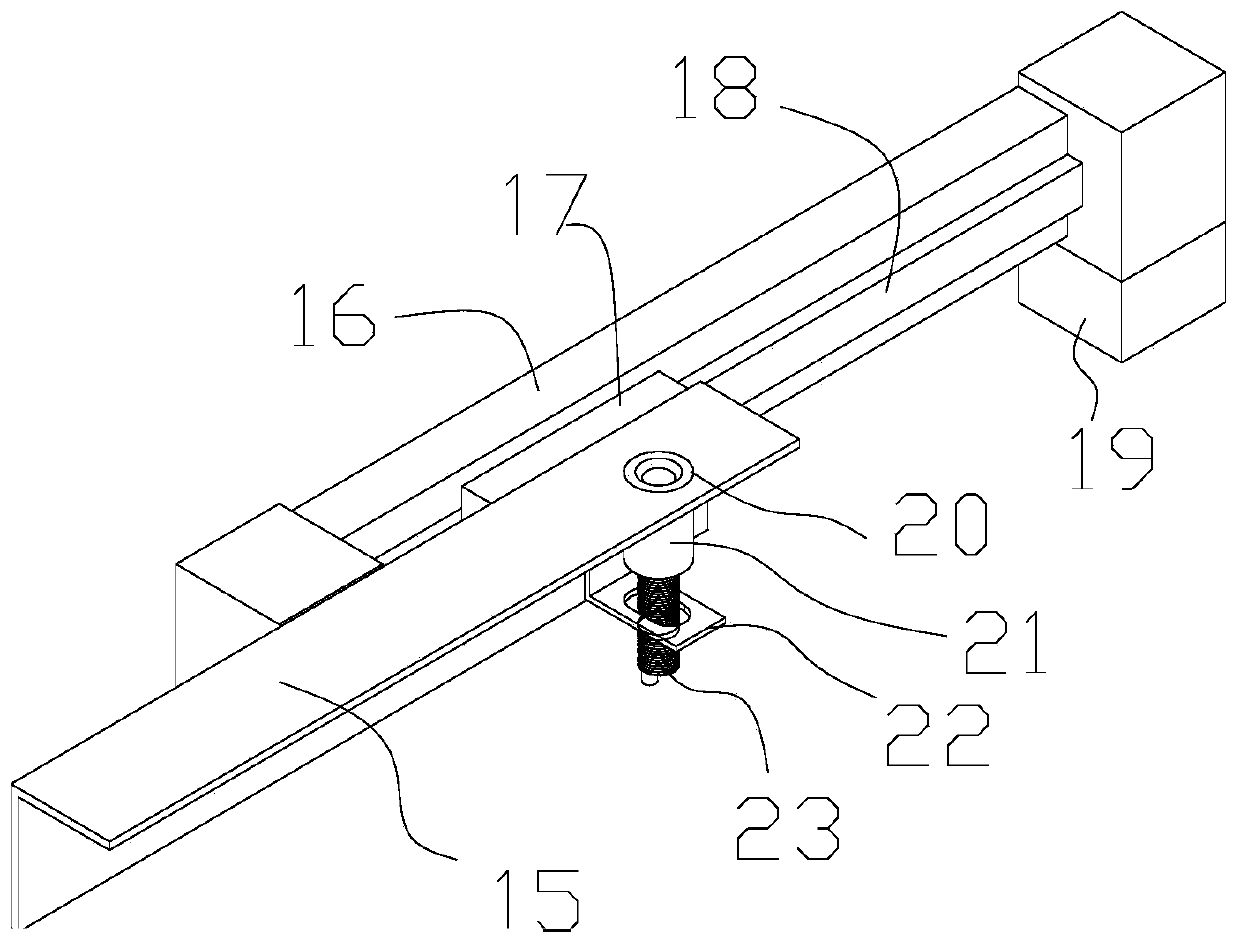

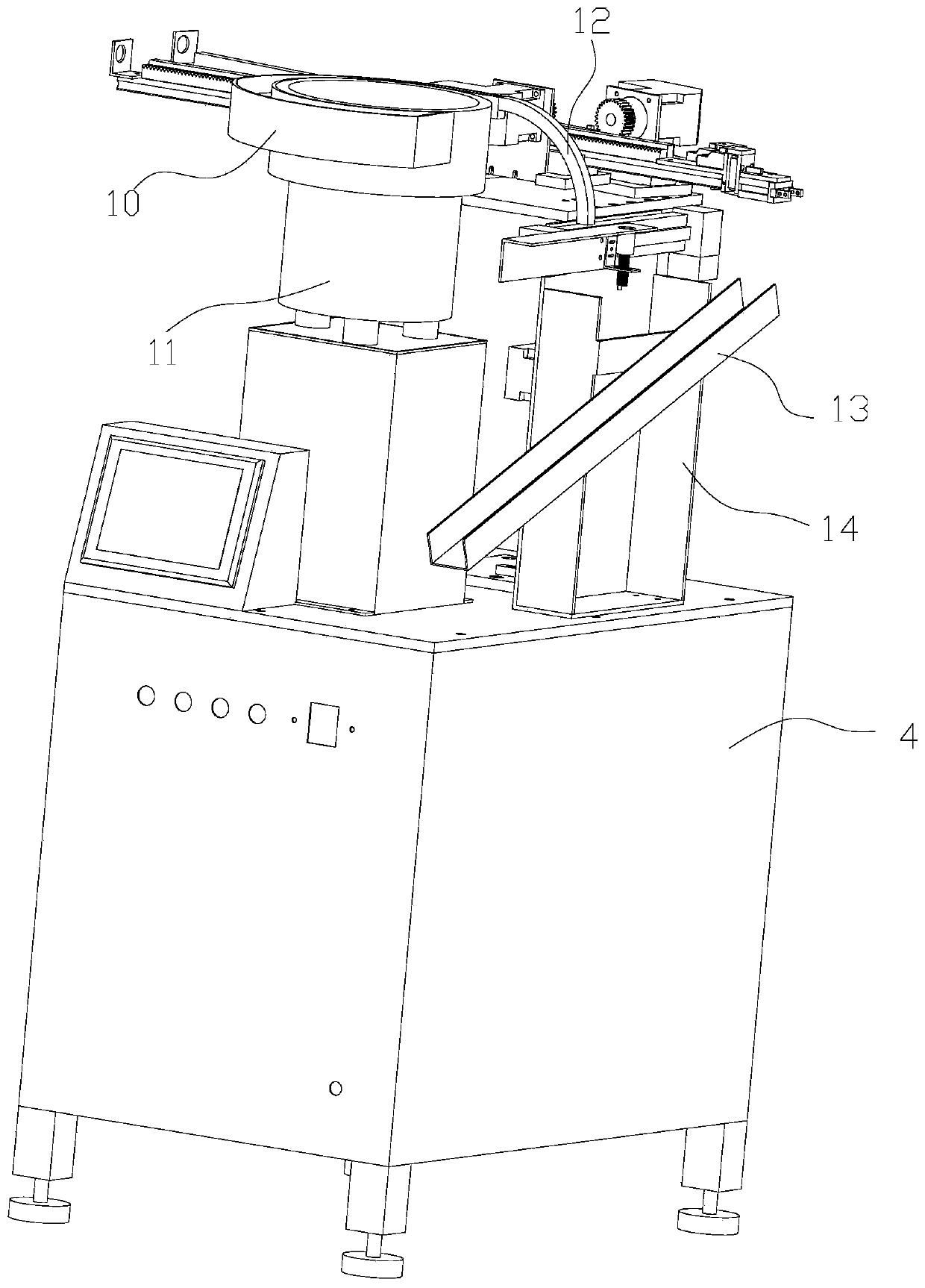

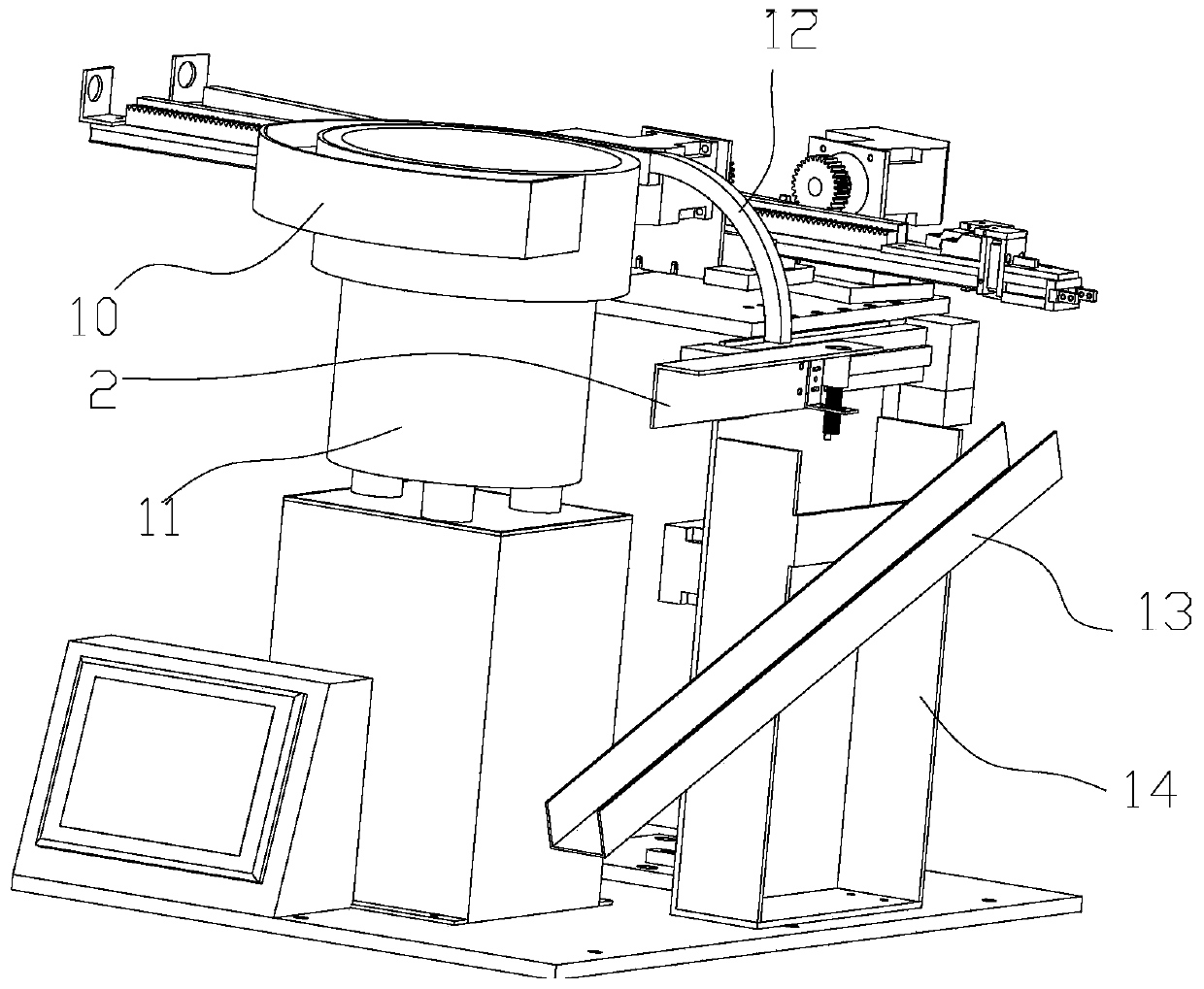

[0028] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0029] This embodiment and the accompanying drawings are all described by taking the present invention installed on a base as an example.

[0030] Such as figure 1 As shown, the present invention as a whole includes a parts discharge mechanism 1, a material transfer mechanism 2, a blanking mechanism 3 and a gripper mechanism 9. The parts to be processed are neatly arranged through the parts discharge mechanism 1 and enter the material transfer mechanism 2 one by one. , the parts are transferred to the gripping mechanism one by one by the material transfer mechanism 2, and the gripping mechanism grabs the parts to be processed from the material transfer mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com