Laminar flow hood supporting frame forming method and supporting frame

A supporting frame and forming method technology, applied to the frame of the engine, supporting machines, mechanical equipment, etc., can solve the problems of long processing time cycle, non-perpendicular polishing, and unequal butt joint placement, achieve short processing time cycle, and improve visual effects , Improve the effect of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

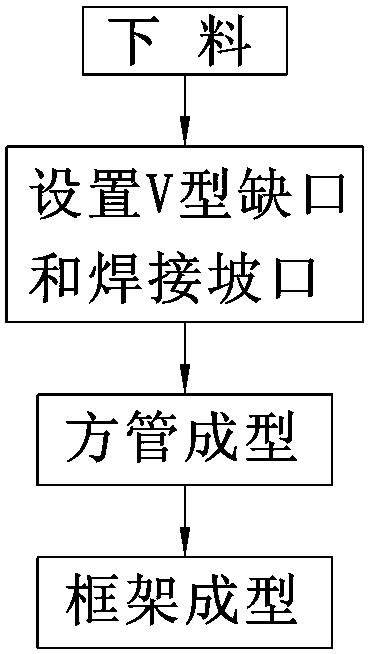

[0043] Figure 1 to Figure 6 The first embodiment of the forming method of the laminar flow hood supporting frame of the present invention is shown, comprising the following steps:

[0044] S1: blanking: blanking a slab whose total length is equal to the perimeter of the required support frame;

[0045] S2: Setting V-shaped notches and welding grooves: cutting V-shaped notches along one side of the slab at each bisector of the slab, and cutting welding grooves at both ends of the slab;

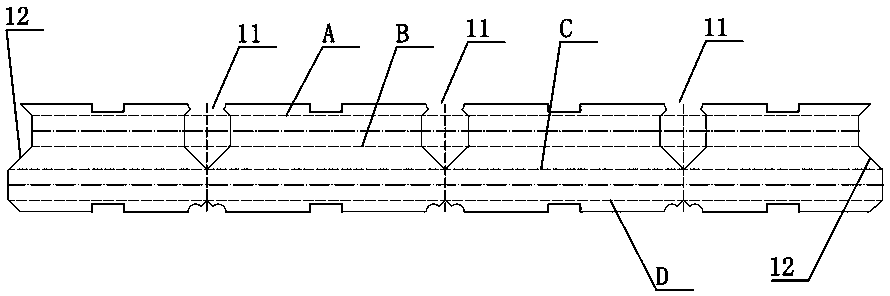

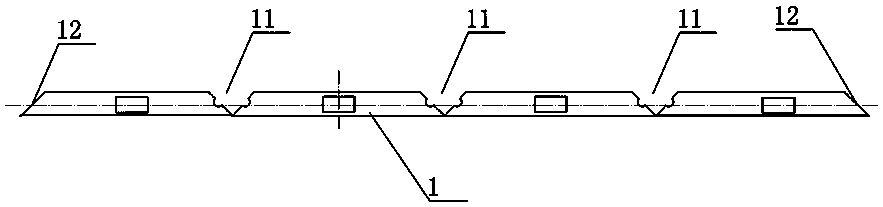

[0046] S3: Square tube forming: set four bending lines A, B, C and D along the slab, and bend the slab into a square tube along the four bending lines, and carry out section welding along the butt edge of the square tube;

[0047] S4: Frame forming: bend the square tube along the three V-shaped notches so that the welding grooves at both ends of the square tube are butted, and perform spot welding and polishing along the three bending lines and the welding grooves.

[0048] With this method,...

Embodiment 2

[0054] Figure 7 to Figure 14 The second embodiment of the forming method of the laminar flow hood supporting frame of the present invention is shown, comprising the following steps:

[0055] S1: blanking: blanking two slabs with different lengths and the sum of the lengths is equal to the circumference of the required support frame, wherein the length of the long slab is three times that of the short slab;

[0056] S2: Set up V-shaped notches and welding grooves: cut V-shaped notches along one side of the slab at each bisector of the long slab, and cut at both ends of the long and short slabs welding groove;

[0057] S3: Square tube forming: set four bending lines A, B, C and D along the long slab and short slab, and bend the long slab and short slab into two square tubes along the four bending lines. Segment welding is carried out on the butt edge of two square pipes;

[0058] S4: Frame forming: bend the rectangular tube into a U-shaped tube along the two V-shaped notches, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com