Manufacturing method in non-shaped state of long rod-shaped MIM product

A manufacturing method and long rod-shaped technology, which is applied to household components, household appliances, and other household appliances, etc., can solve problems such as easy generation of internal stress, high cost, and deformation of product rods, so as to avoid fracture or deformation and reduce manufacturing process Process, the effect of saving manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical points of the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

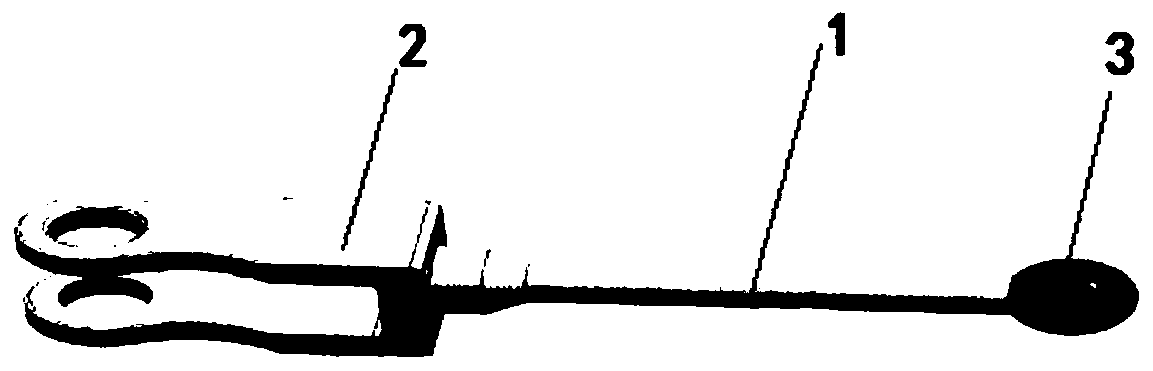

[0022] Such as figure 1 As shown, this long-rod-shaped MIM product is a push rod component connected to an automobile clutch, including a straight rod part 1, one end of the straight rod part 1 is a U-shaped fork part 2, and the other end is a ball 3.

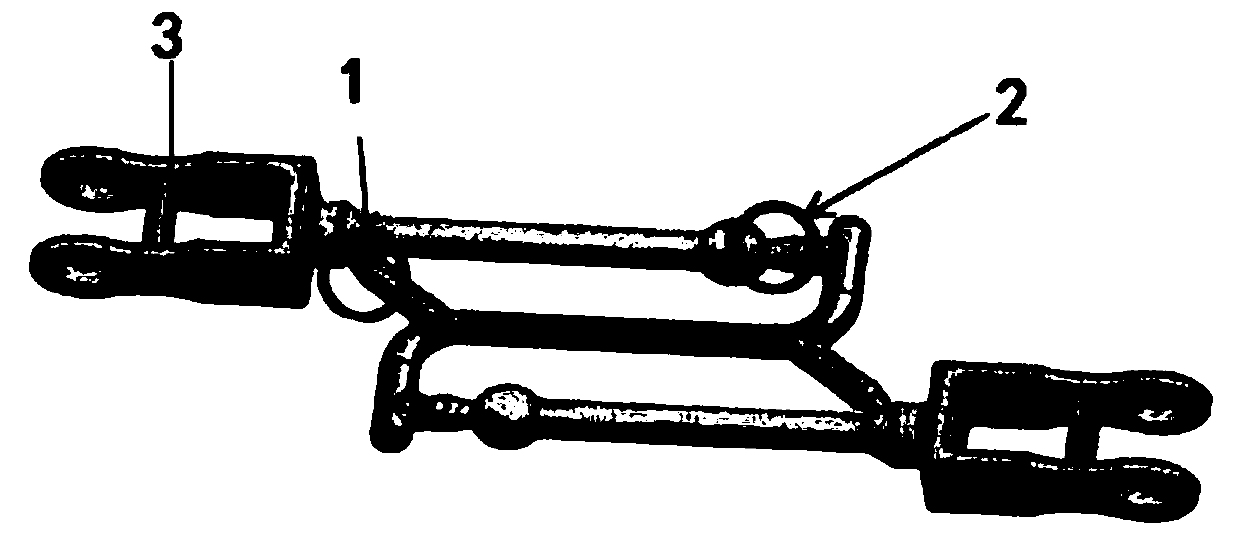

[0023] The manufacturing method of the above-mentioned long-rod MIM product in the non-reshaping state adopts high-temperature material double-gate glue injection, and adds reinforcement ribs to the middle part of the "U"-shaped mouth; the reverse compensation is added to the mold in the upper and lower directions of the "U"-shaped mouth; use Dedicated sintered support plate.

[0024] Such as figure 2 As shown, the first gate 4 of the double gates is set at the junction of the straight rod part and the U-shaped fork, and the second gate 4 is set on the sphere. More sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com