Gripper for stacking robot

A technology of palletizing robot and sliding table mechanism, which is applied to conveyors, stacking of objects, conveyor objects, etc., can solve the problem of increased box placement space, large gap between boxes and boxes, storage and handling problems and other problems, to achieve the effect of improving space utilization, convenient fixing and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

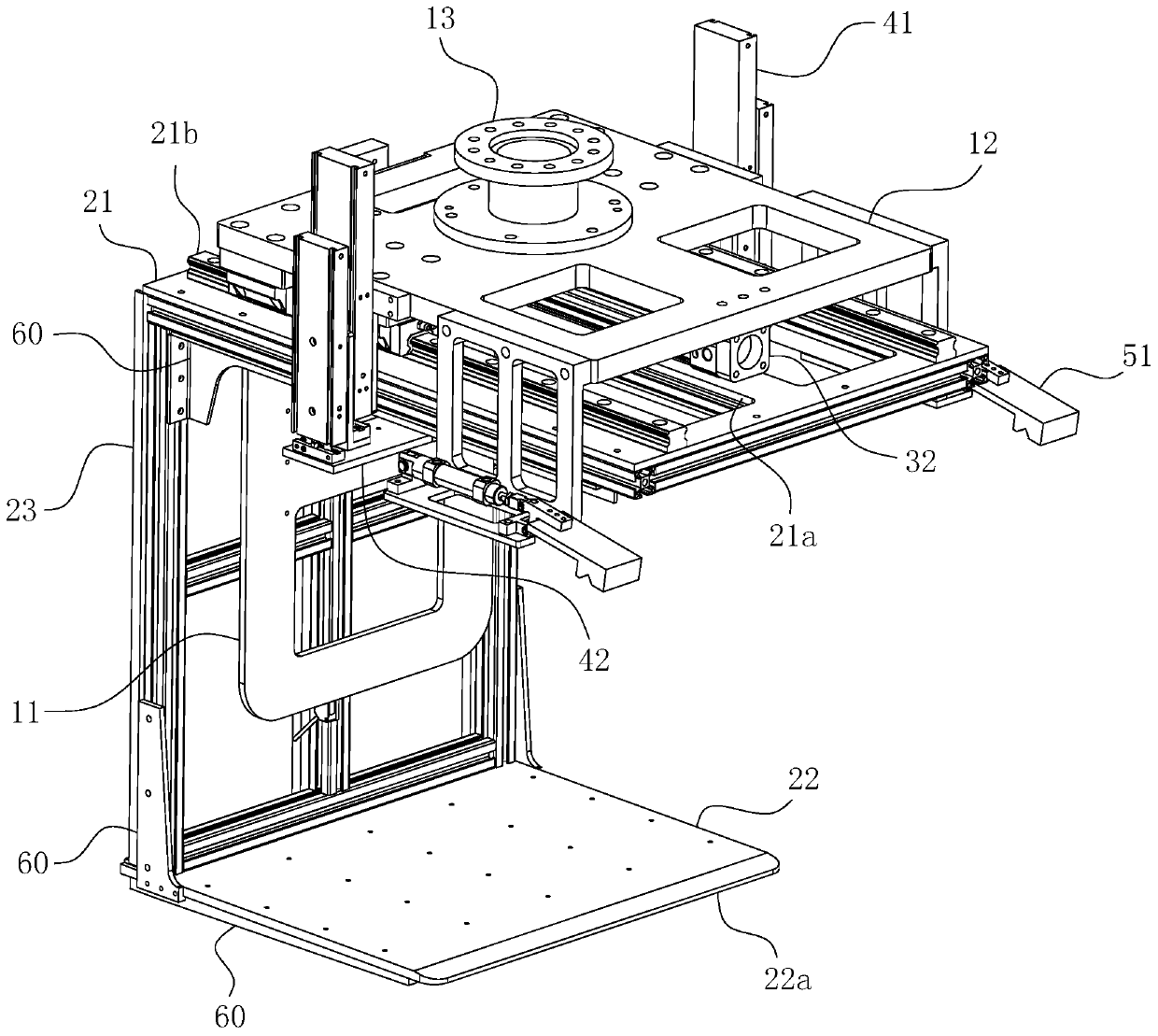

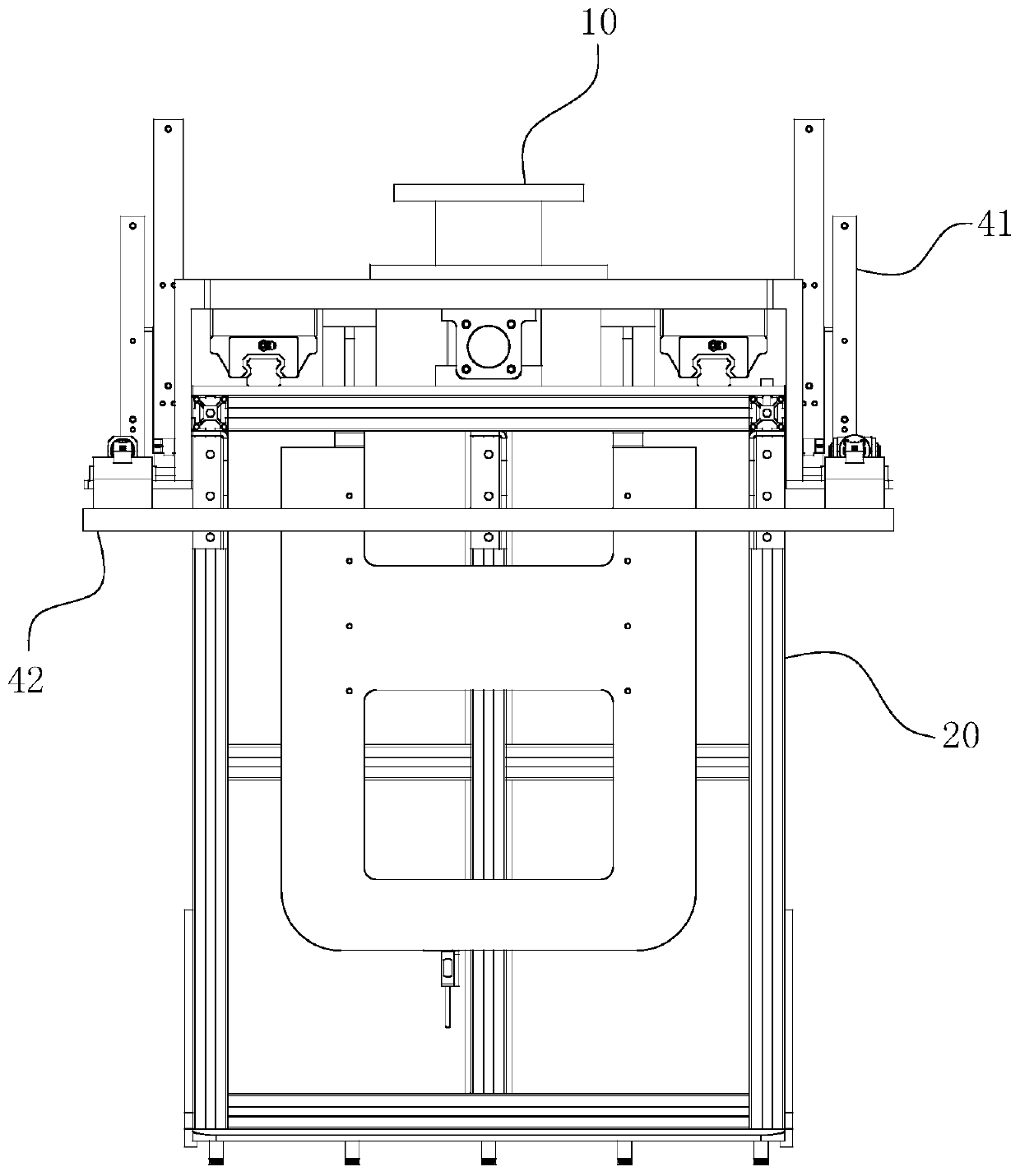

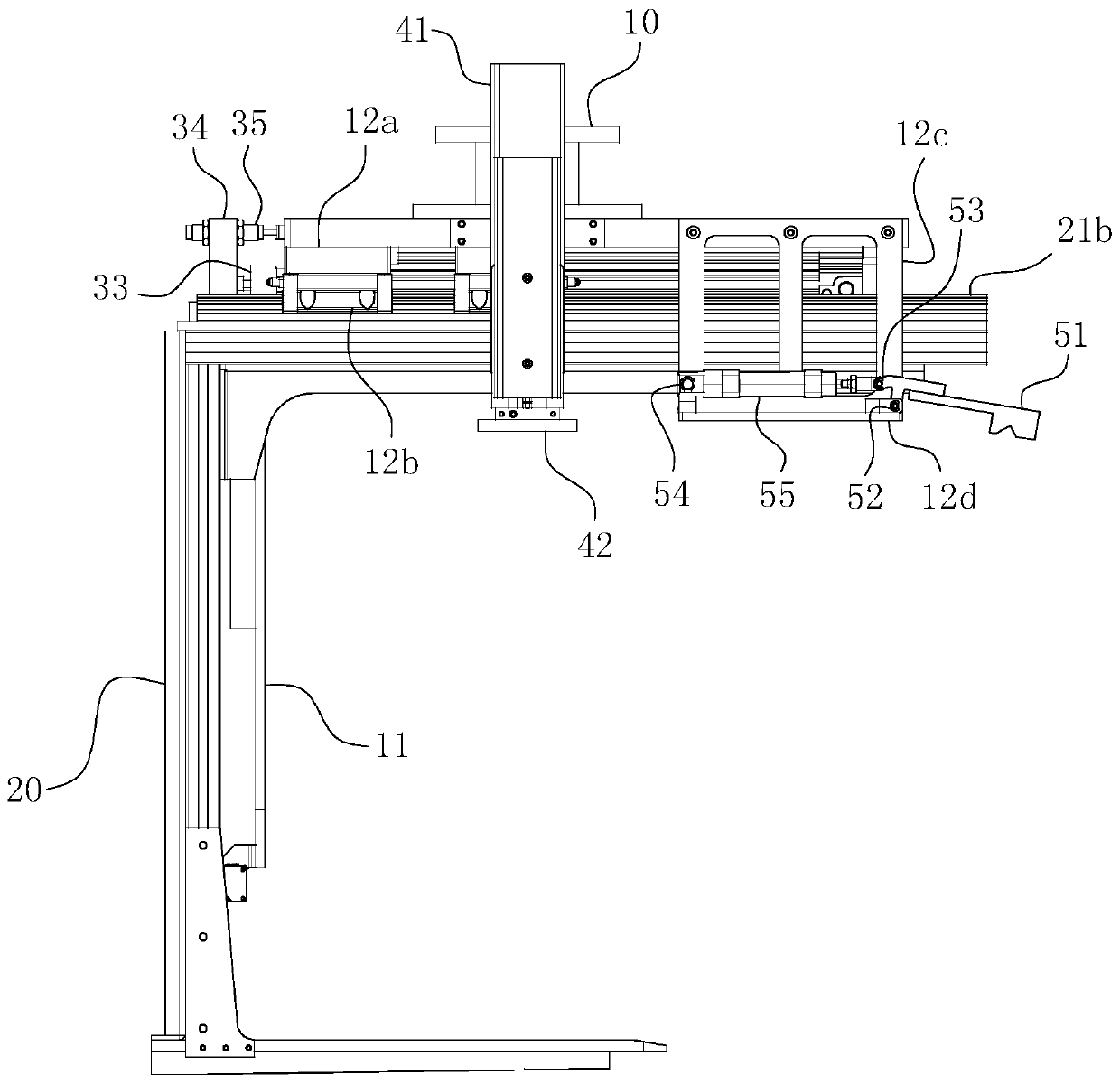

[0046] For ease of understanding, combined here Figure 1-7 , the concrete structure and working mode of the present invention are further described as follows:

[0047] The specific structure of the present invention is as Figure 1-7 As shown, its main structure consists of a static part directly connected to the mechanical arm of the palletizing robot, a moving part that can be reciprocated relative to the static part, a pressing part for pressing the box body, and a block that prevents the box from moving outwards. The blocker consists of four parts. in:

[0048] The static part includes a mounting flange 13 , a mounting baffle 12 and a vertical baffle 11 . The bottom end of the mounting flange 13 is affixed to the top end of the mounting baffle plate 12, thereby combining to form the mounting seat 10 directly matched with the mechanical arm. The tail end of the mount 10 is also image 3 The left end is fixedly connected to the top of the vertical baffle 11 , that is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com