Direct type soil moisture content detection equipment

A soil moisture content detection equipment technology, applied in the field of direct soil moisture content detection equipment, can solve the problems of inaccurate detection, incomplete liquid volume, and inability to evaporate water vapor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

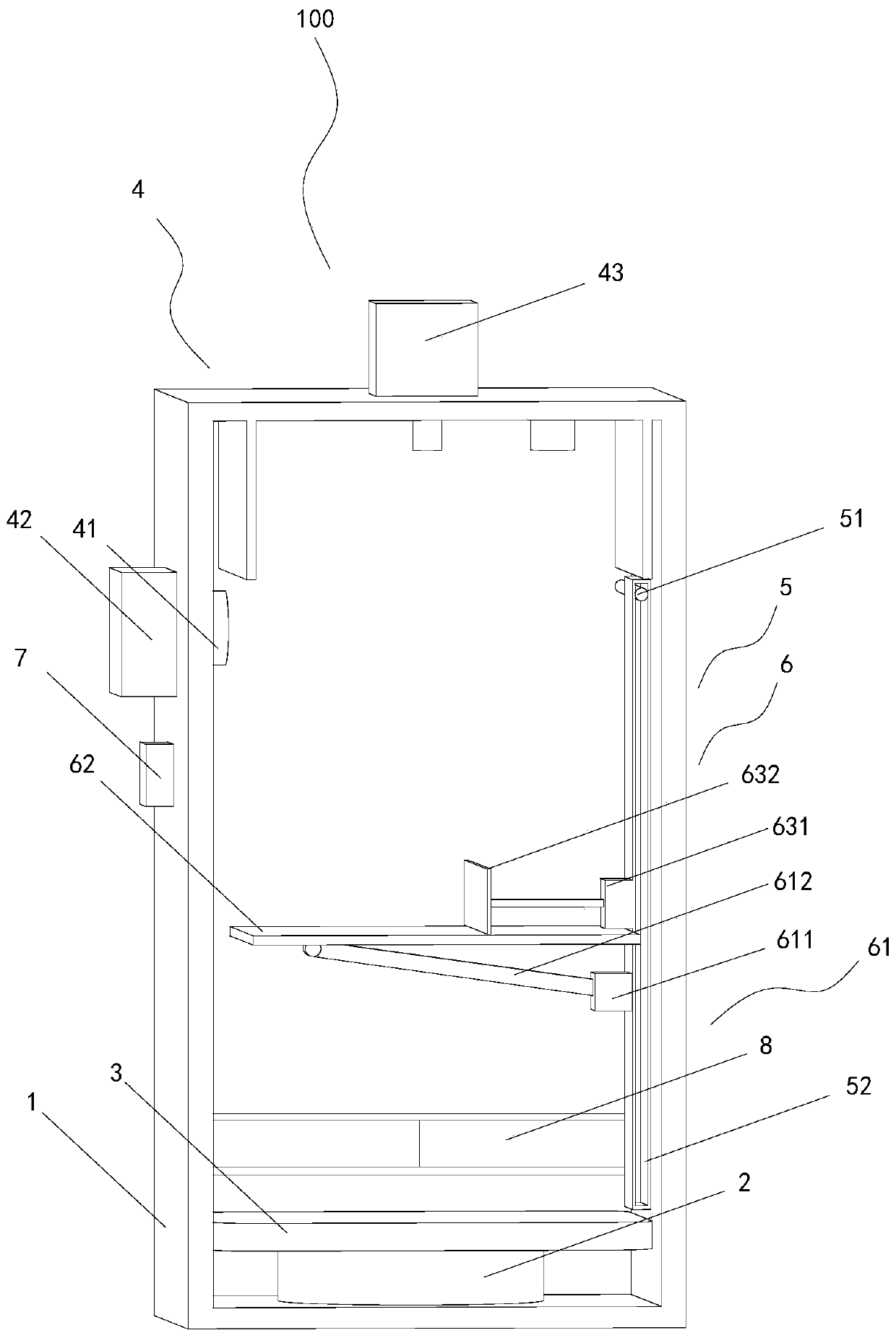

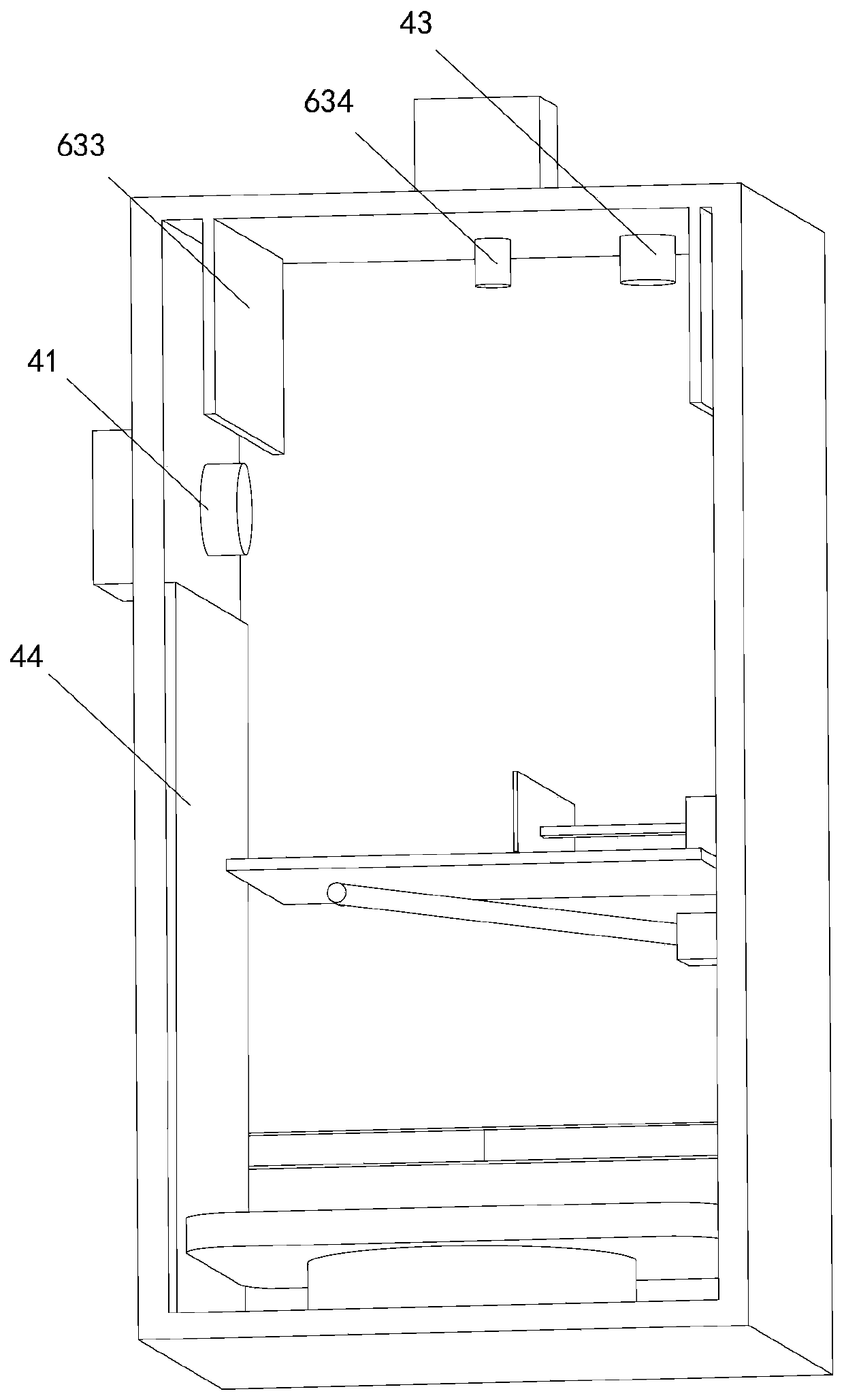

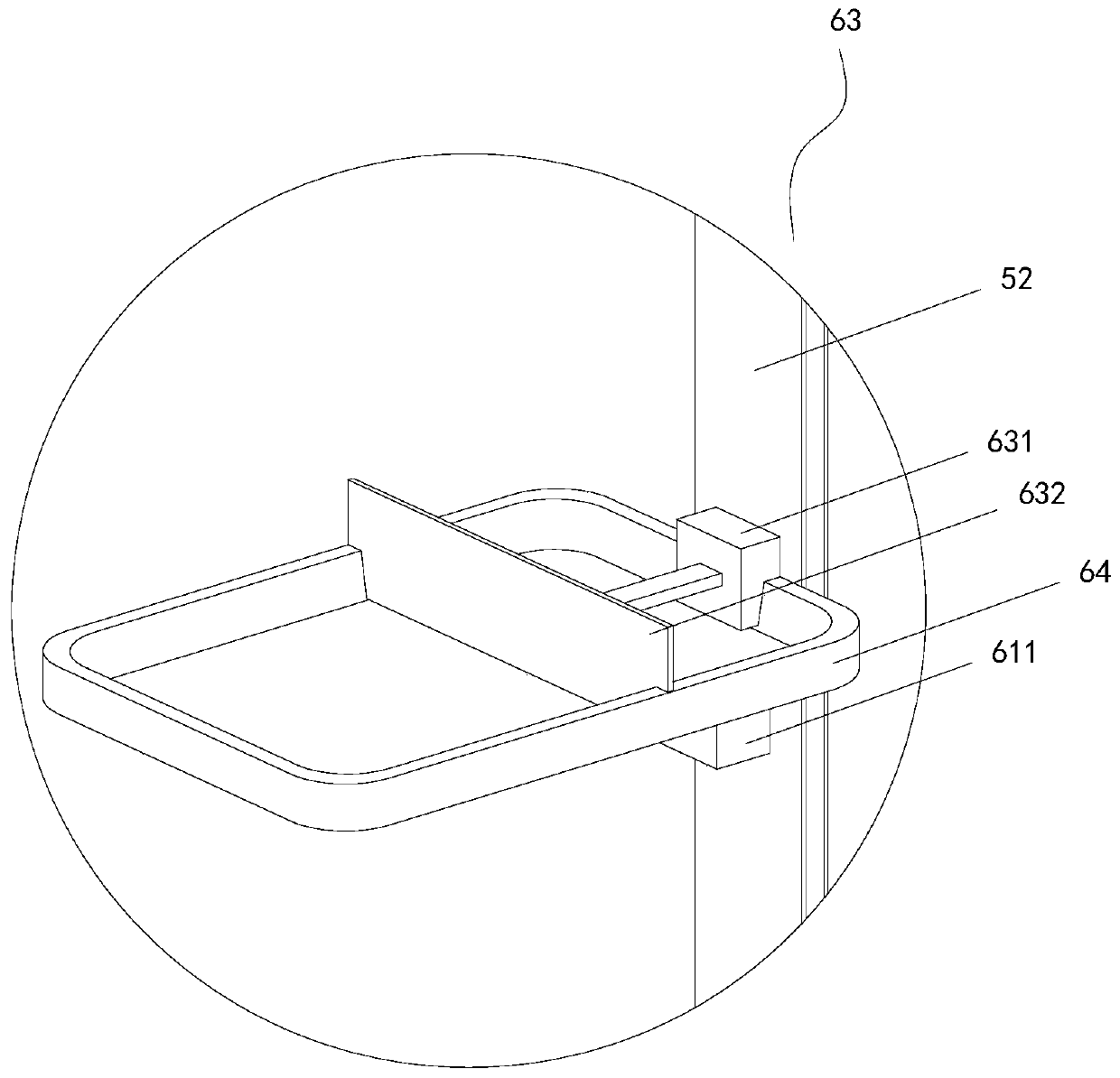

[0024] see Figure 1 to Figure 3 , the present invention provides a direct soil moisture content detection device 100, comprising a housing 1, a weighing platform 2, a storage box 3, an exhaust device 4, a transmission device 5 and a filtering device 6; the weighing platform 2 and the The casing 1 is fixedly connected and located inside the casing 1 and at the bottom of the casing 1. The storage box 3 abuts against the weighing platform 2 and is located away from the weighing platform 2. One side of the housing 1, the exhaust device 4 is fixedly connected to the housing 1, and is located inside the housing 1, and is located on the side of the housing 1 away from the weighing platform 2, so The transmission device 5 is fixedly connected with the housing 1, and is located inside the housing 1, and is located between the storage box 3 and the exhaust device 4, and the filter device 6 and the transmission device 5 is slidingly connected, and is located between the storage box 3 a...

no. 2 example

[0031] see figure 1 and figure 2 , the present invention provides a direct soil moisture content detection device 100, comprising a housing 1, a weighing platform 2, a storage box 3, an exhaust device 4, a transmission device 5 and a filtering device 6; the weighing platform 2 and the The casing 1 is fixedly connected and located inside the casing 1 and at the bottom of the casing 1. The storage box 3 abuts against the weighing platform 2 and is located away from the weighing platform 2. One side of the housing 1, the exhaust device 4 is fixedly connected to the housing 1, and is located inside the housing 1, and is located on the side of the housing 1 away from the weighing platform 2, so The transmission device 5 is fixedly connected with the housing 1, and is located inside the housing 1, and is located between the storage box 3 and the exhaust device 4, and the filter device 6 and the transmission device 5 is slidingly connected, and is located between the storage box 3...

no. 3 example

[0038] see figure 1 and figure 2 , the present invention provides a direct soil moisture content detection device 100, comprising a housing 1, a weighing platform 2, a storage box 3, an exhaust device 4, a transmission device 5 and a filtering device 6; the weighing platform 2 and the The casing 1 is fixedly connected and located inside the casing 1 and at the bottom of the casing 1. The storage box 3 abuts against the weighing platform 2 and is located away from the weighing platform 2. One side of the housing 1, the exhaust device 4 is fixedly connected to the housing 1, and is located inside the housing 1, and is located on the side of the housing 1 away from the weighing platform 2, so The transmission device 5 is fixedly connected with the housing 1, and is located inside the housing 1, and is located between the storage box 3 and the exhaust device 4, and the filter device 6 and the transmission device 5 is slidingly connected, and is located between the storage box 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com