Underground metal mine goaf hazard degree grading evaluation method

An evaluation method and goaf technology, applied in the field of underground mine safety, can solve many problems such as inaccurate goaf risk level and inconsistent evaluation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

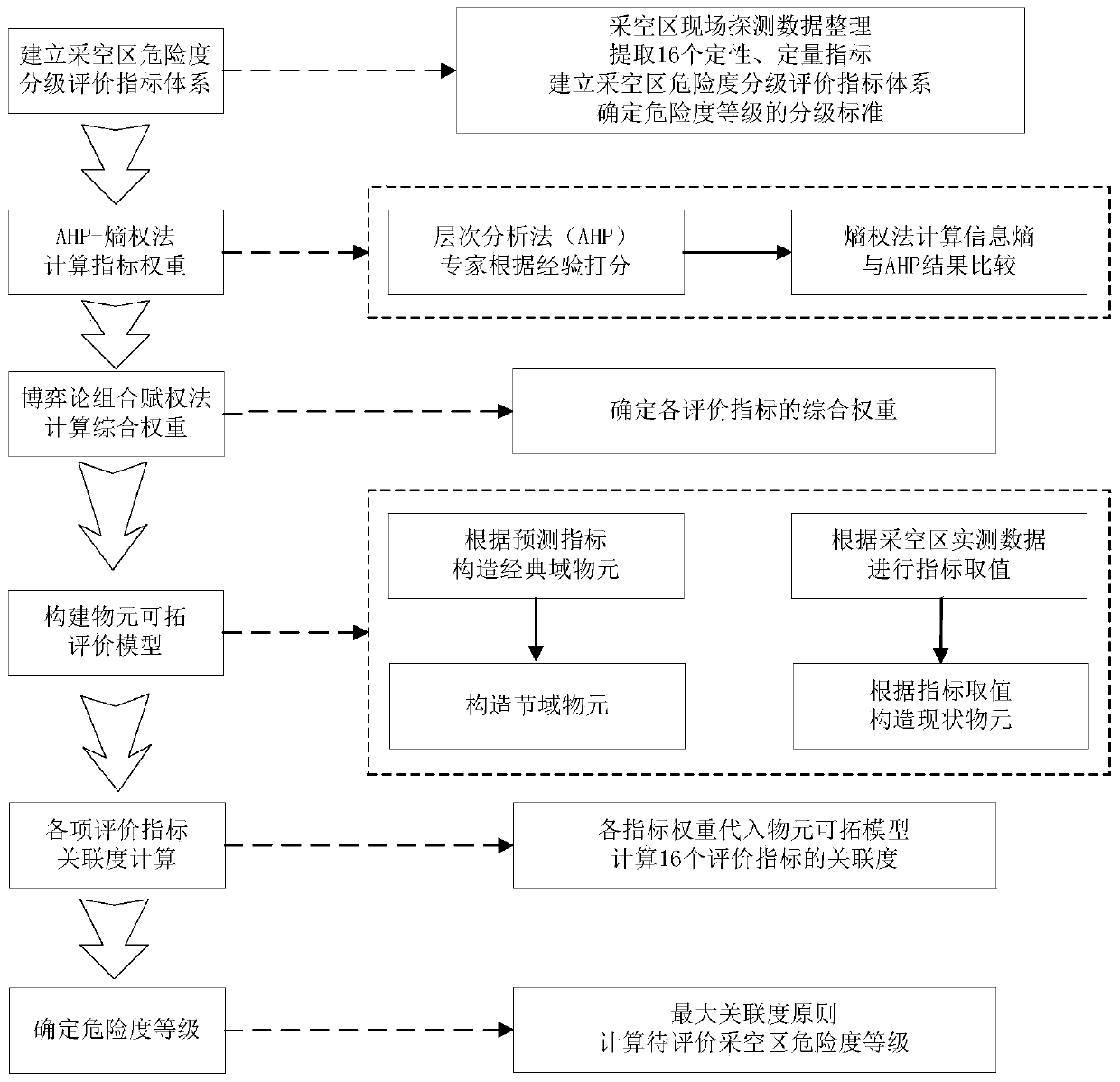

[0168] Step 1: Conduct on-site detection of goafs in underground metal mines, and collect engineering geological data related to goafs.

[0169] Step 2: Establish the evaluation index system of goaf risk classification and determine the classification standard of risk degree;

[0170] Comprehensively considering the actual situation of the goaf in underground metal mines, the type of goaf is selected (X 1 ), geological structure (X 2 ), rock structure (X 3 ), surrounding rock support (X 4 ), roof features (X 5 ), surface features (X 6 ), hydrological factors (X 7 ), the distribution of adjacent empty areas (X 8) , engineering layout (X 9 ), goaf size (X 10 ), buried depth / m(X 11 ), high-span ratio (X 12 ), exposed area / m 2 (X 13 ), pillar safety factor (X 14 ), rock compressive strength / Mpa(X 15 ), rock quality standard (X 16) with a total of 16 indicators to establish a goaf risk classification evaluation index system. Among them, the goaf type, geological str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com