Rectangular liquid tank sloshing damping device and rectangular liquid tank hydrodynamic calculation method

A liquid tank sloshing and damping device technology, applied in calculation, transportation and packaging, for bulk cargo, etc., can solve the problems of reducing water body exchange and effective volume, local horizontal solid plates cannot provide sloshing damping, etc., to ensure Effects of rigor and validity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

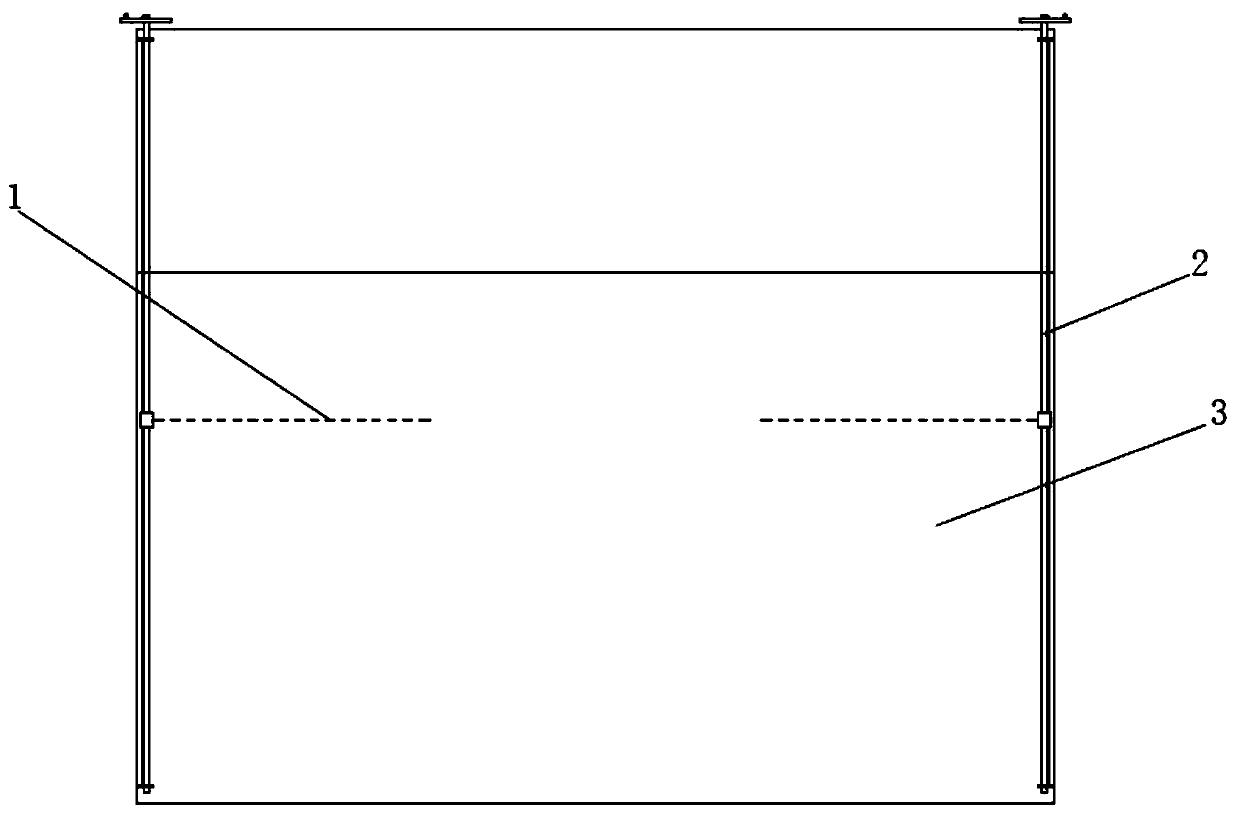

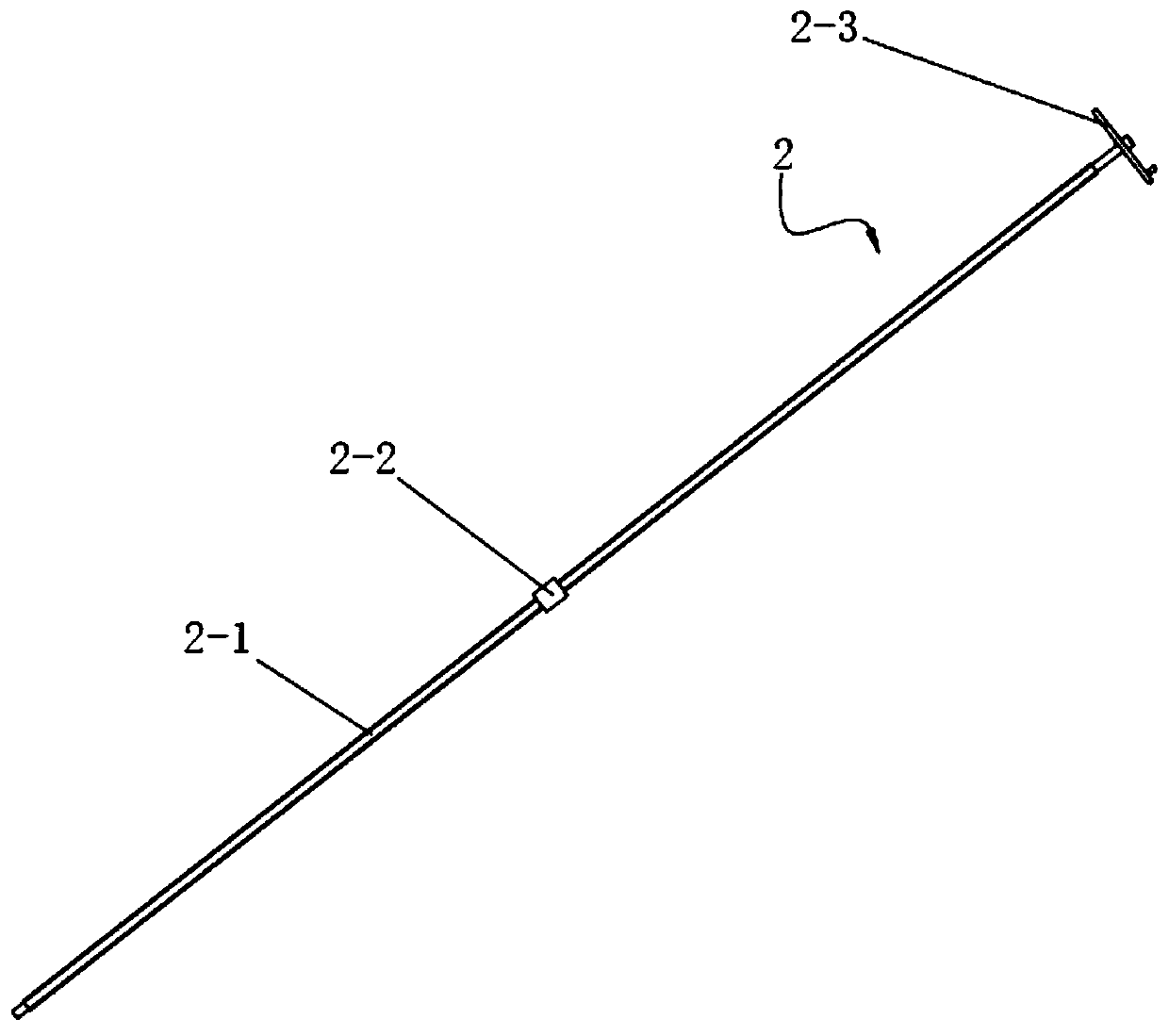

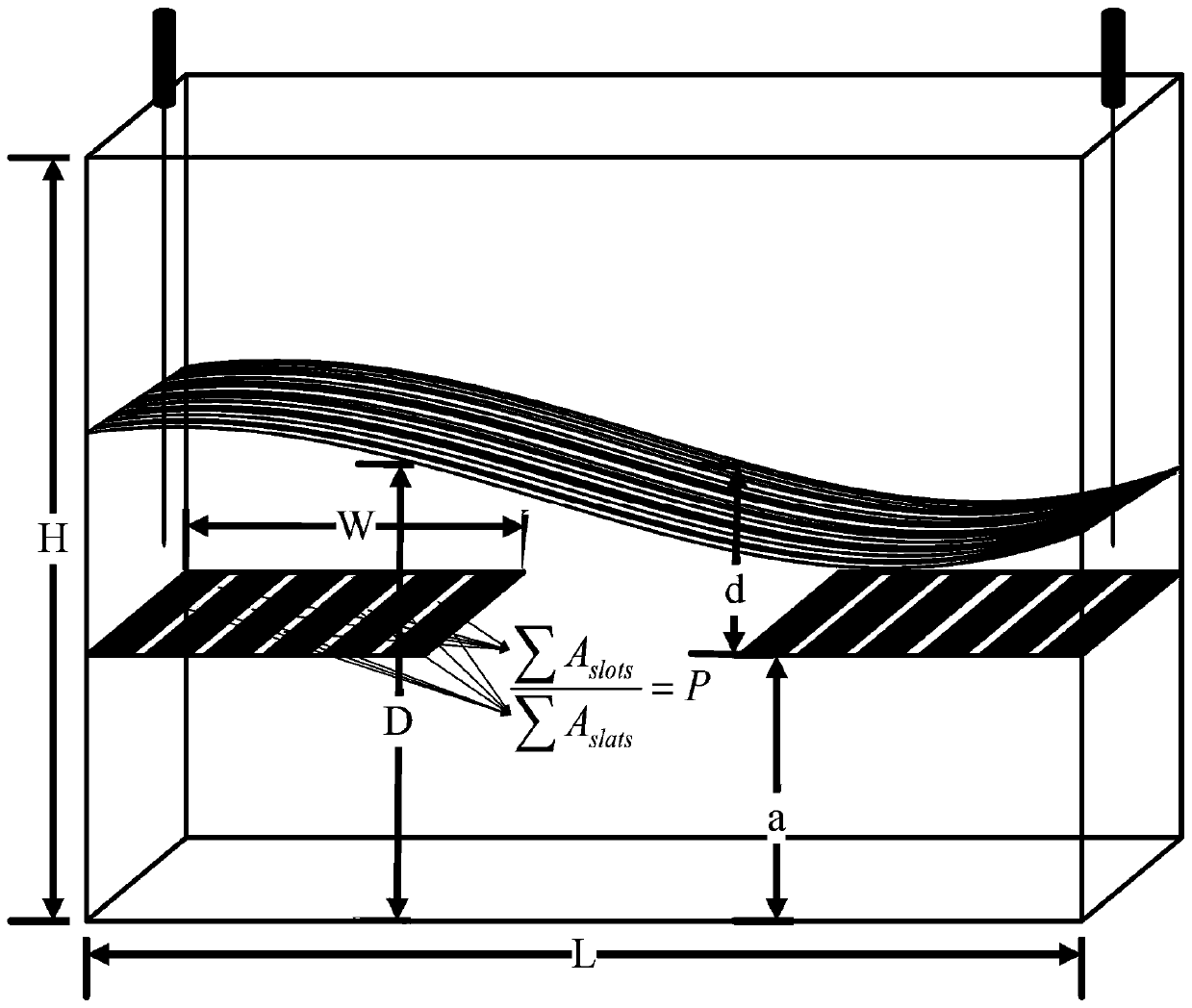

[0050] Such as figure 1 As shown, a rectangular liquid tank sloshing damping device includes a pair of symmetrically distributed horizontal partitions 1 separated by a certain distance; a pair of horizontal partitions 1 are installed to the corresponding on the inner wall of the liquid tank 3, and adjust the position in the height direction of the liquid tank 3 through the screw slider mechanism 2; as figure 2 As shown, the screw slider mechanism 2 includes a screw 2-1 extending along the height direction of the tank 3, a slider 2-2 reciprocating along the screw 2-1 and a hand wheel 2-3 , wherein, a threaded rod 2-1 is fixed to the inner wall of the liquid tank 3 through a pair of mounts, one side of the rod end extends from the top opening of the liquid tank 3 to the outside of the liquid tank 3, and a hand wheel 2-3 is installed To the end of the side rod, by adjusting the hand wheel 2-3, the slider 2-2 can be conveniently driven to move and position along the axial direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com