Pipeline conveying device in limited work space

A work space and conveying device technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as affecting road traffic, unfavorable resource optimal allocation, dust pollution, etc., and achieve the effect of reducing manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, not to limit the present invention.

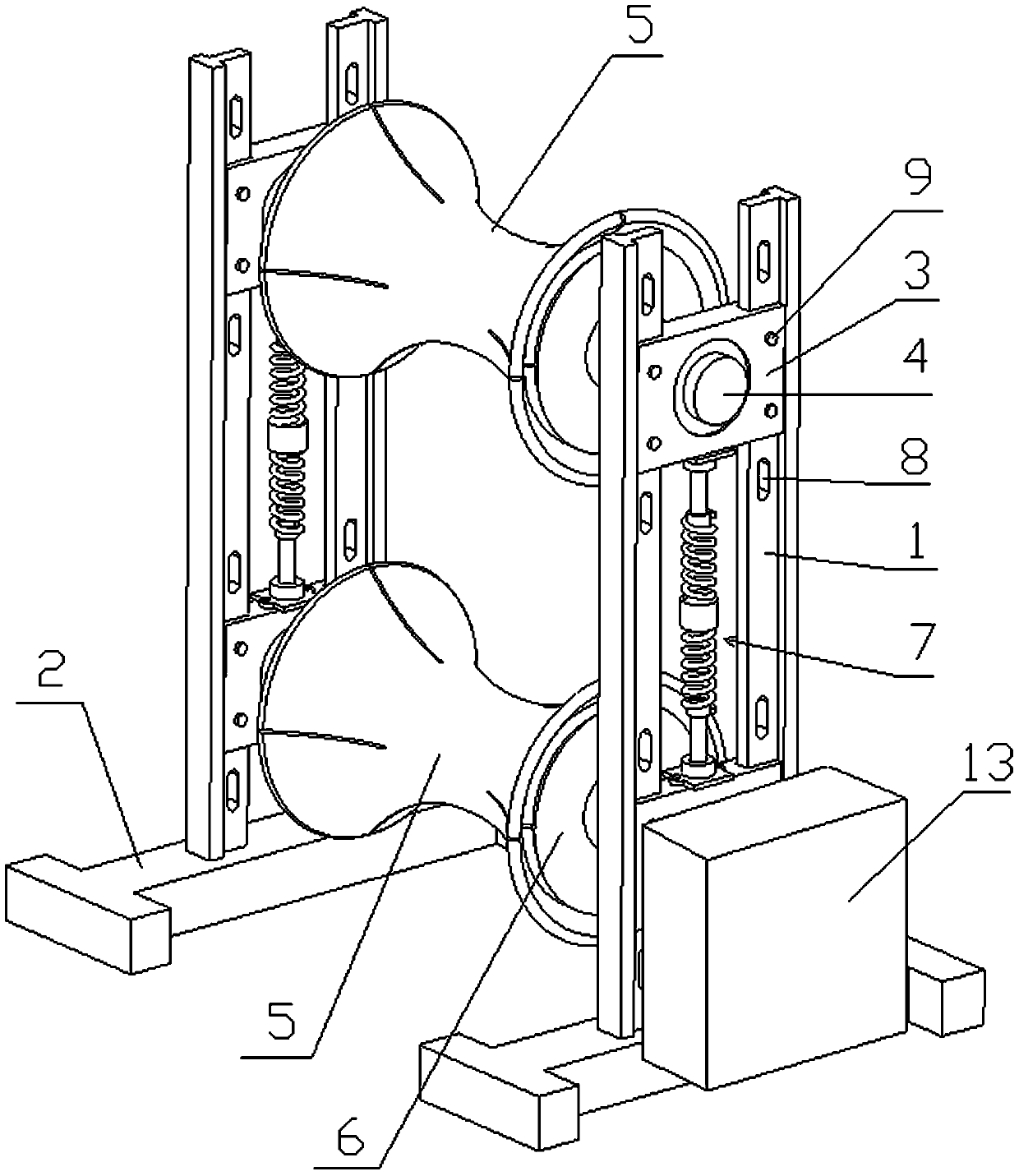

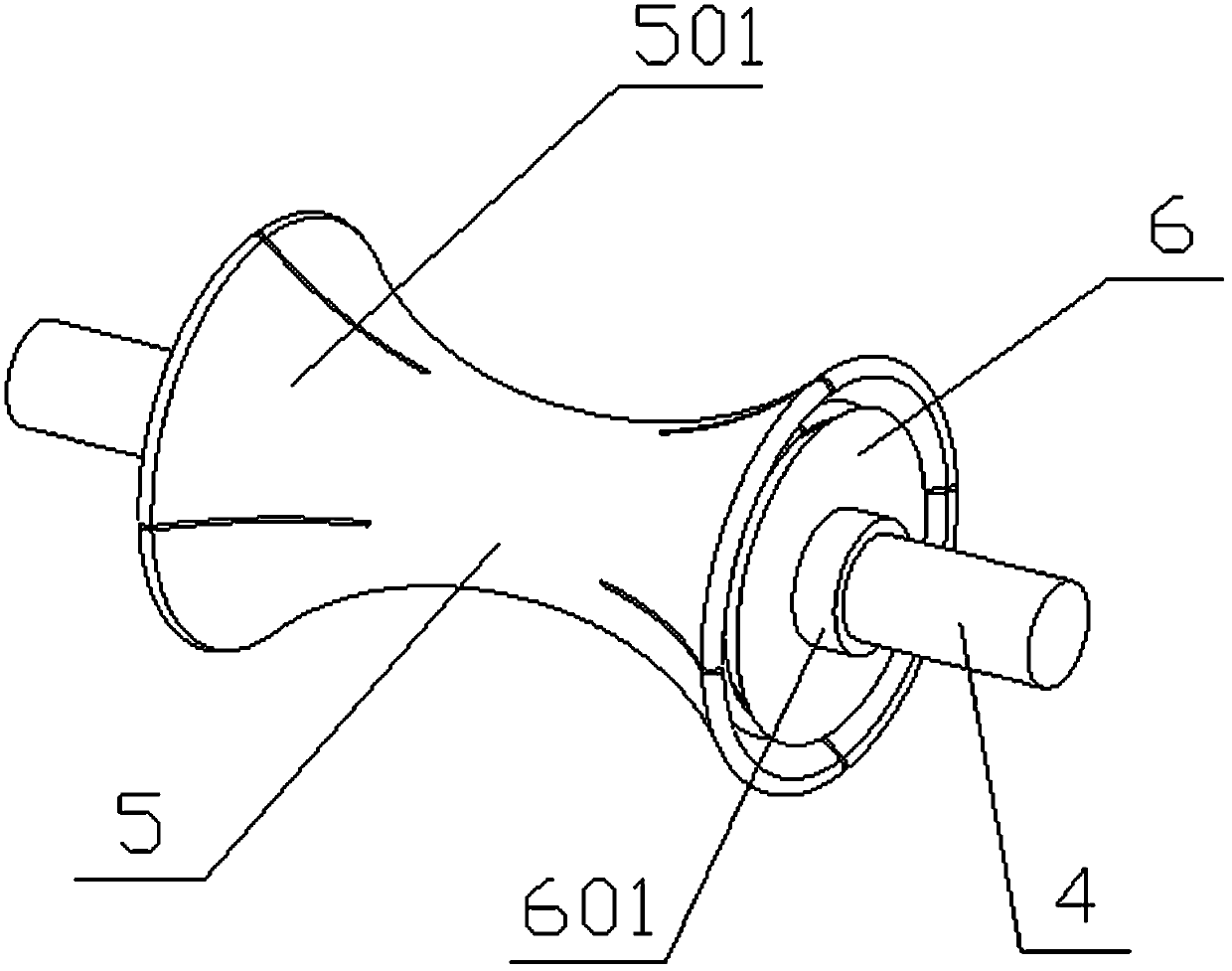

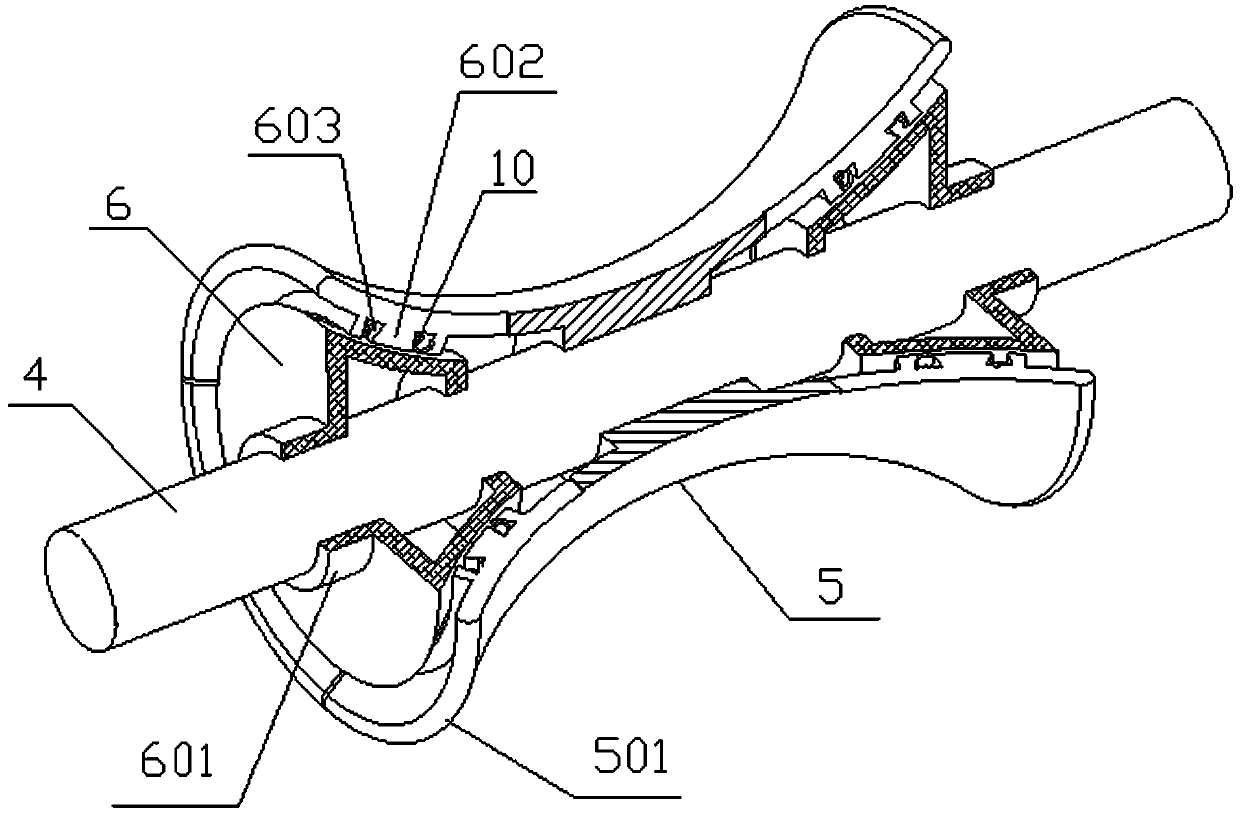

[0027] The invention discloses a pipeline conveying device in a limited working space, such as figure 1 Shown, base 2, frame 1 and two conveying rollers, wherein, frame 1 is vertically installed on the base 2, and two conveying rollers are installed on the frame 1 movablely at intervals along the vertical direction, each conveying roller The outer peripheral surface is a concave arc surface, and the two axial ends of each conveying roller are respectively movably connected with a curvature adjusting mechanism 6 which can change the curvature of the arc surface, and an elastic tightening mechanism 7 is arranged between the two conveying rollers , and at least one of the two conveying ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com