Cable bridge provided with adjustable wiring assembly

A cable tray and adjustable technology, applied in electrical components and other directions, can solve the problems of short service life, easy accumulation of cables and disorder, affecting repair and maintenance, etc., to shorten the working time, improve the laying efficiency, and improve the utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030]A cable tray equipped with adjustable wiring components includes a bracket 1. The top of the bracket 1 is fastened with a cover 2, and the outer wall of the cover 2 and the bracket 1 are coated with an anti-corrosion coating 3. The material of layer 3 is epoxy resin, and the anti-corrosion coating 3 can prevent the cover 2 and the bracket 1 from corrosion, thereby prolonging the service life. The outer wall of the cover 2 is equipped with bolts 4, and the inner wall of the bolts 4 The end is threadedly connected with the outer wall of the bracket 1 through the threaded groove 5, and the bolt 4 serves to fasten the cover body 2 and the bracket 1.

Embodiment 2

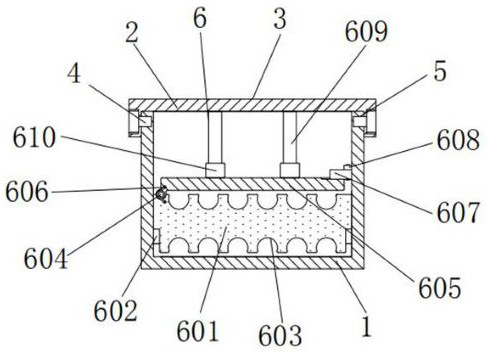

[0032]As an optional case, seefigure 1 with6, A cable tray with adjustable wiring components, wiring component 6 includes horizontal plate 601, bump 602, groove 603, round rod 604, pressure plate 605, torsion spring 606, bracket 607, clamp rod 608, vertical rod 609 and rubber In the sleeve 610, the outer wall of the horizontal plate 601 is in clearance fit with the inner wall of the bracket 1. The upper and lower ends of the horizontal plate 601 are provided with bumps 602. The outer ends of the bumps 602 are fixedly connected with the inner wall of the bracket 1 on the left and right sides. The inner side of the top of the block 602 is clamped with the outer end of the horizontal plate 601. The convex block 602 supports the horizontal plate 601. The inner side of the convex block 602 is provided with grooves 603, which are arranged horizontally and equidistantly. The grooves 603 are distributed in double rows with respect to the horizontal plate 601. This design can realize the dou...

Embodiment 3

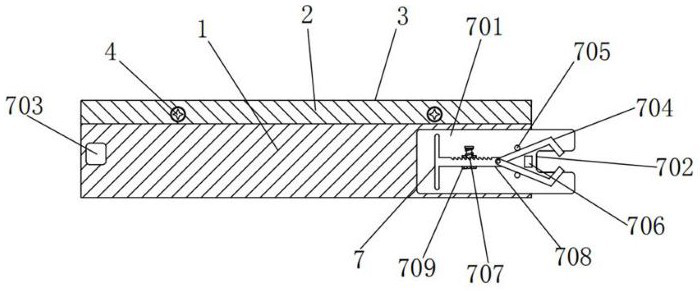

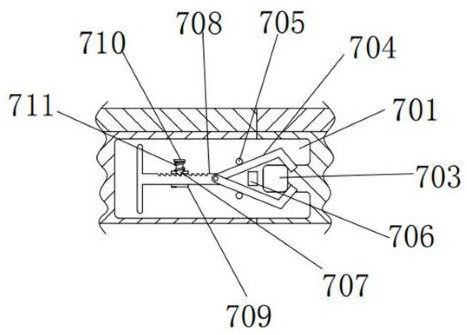

[0035]As an optional case, seeFigure 2-5, A cable tray with adjustable wiring components. Both sides of the front and left side of the bracket 1 are equipped with connecting components 7. The connecting components 7 include support plate 701, slot 702, insert block 703, clamp rod 704, short rod 705 , Top block 706, bayonet 707, rack 708, collar 709, baffle 710 and tension spring 711, the rear end of the support plate 701 is fixedly connected with the front right end of the bracket 1, and the right end of the support plate 701 is provided with an insert Slot 702, slot 702 is processed on the right end of support plate 701, the left side of slot 702 is provided with insert block 703, the rear end of insert block 703 is fixedly connected with the front left side of bracket 1, insert block 703 and slot 702 When the two brackets 1 are connected, they can be used for horizontal positioning. The front of the support plate 701 is provided with a clamping rod 704, the left end of the clampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com