Aluminum sheet stacking equipment

An aluminum sheet and palletizing technology, which is applied in the field of aluminum sheet palletizing equipment, can solve problems such as difficult oval aluminum sheet palletizing, and achieve the effects of improving production efficiency, ensuring the quality of palletizing, and broadening the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing.

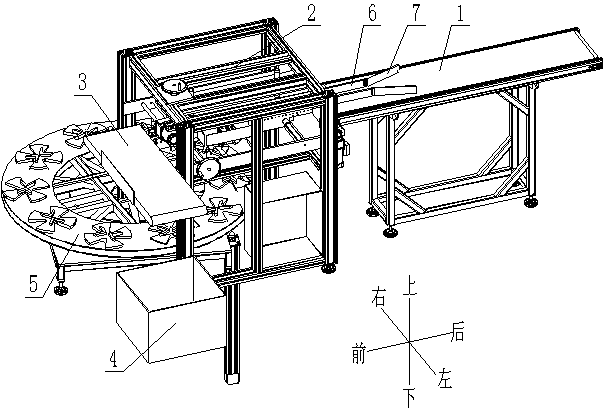

[0032] Such as Figure 1 to Figure 12 The shown a kind of aluminum sheet palletizing equipment, comprises machine head 2 and material receiving device 5;

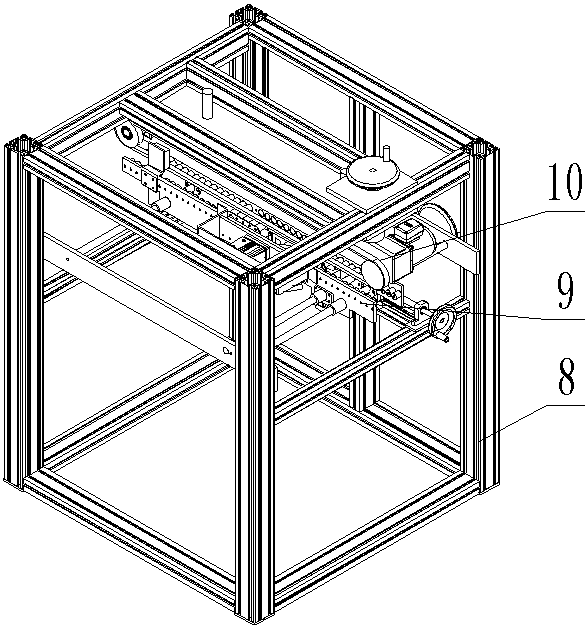

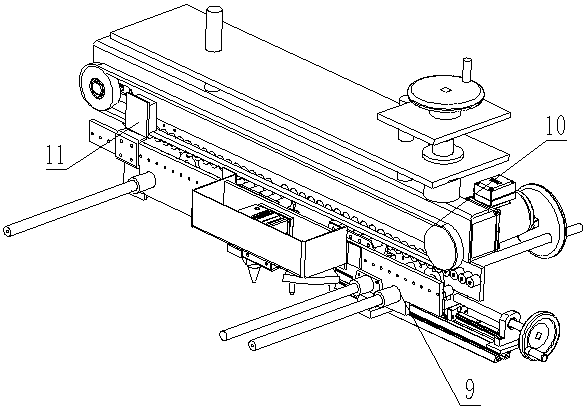

[0033] The head 2 includes a frame 8, a blanking assembly 9 mounted on the frame 8 and a secondary conveyor belt 10 mounted on the frame 8,

[0034] The blanking assembly 9 includes two strip side panels 12 installed on the frame 8, and the two strip side panels 12 extend along the front and rear directions, and the two strip side panels 12 are opposite and parallelly arranged; each strip side panel The outside of the middle part of the plate 12 is fixedly equipped with a first support 13, the first cylinder 14 is fixedly installed on the first support 13, the output shaft of the first cylinder 14 is equipped with a mounting seat 15, and the mounting seat 15 is provided with front and rear The first roller group 16 arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com