A rough wall sizing machine

A blank and drive motor technology, applied in construction, building construction, etc., can solve the problems of construction workers who are prone to fatigue and low work efficiency, and achieve the effect of saving cement mortar and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

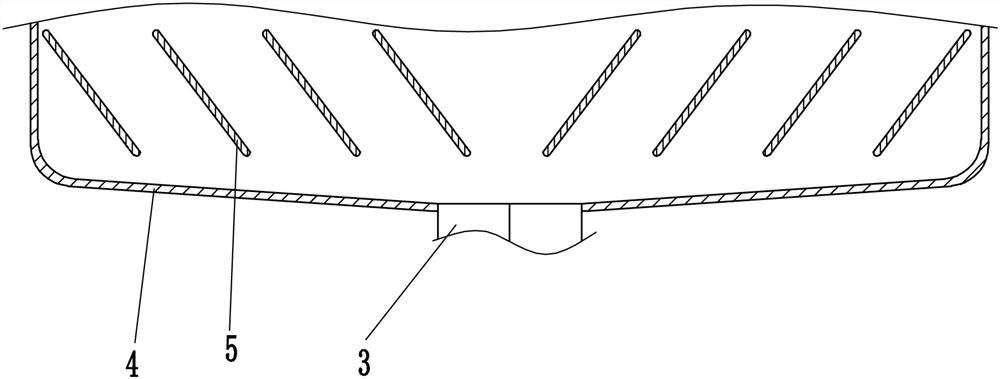

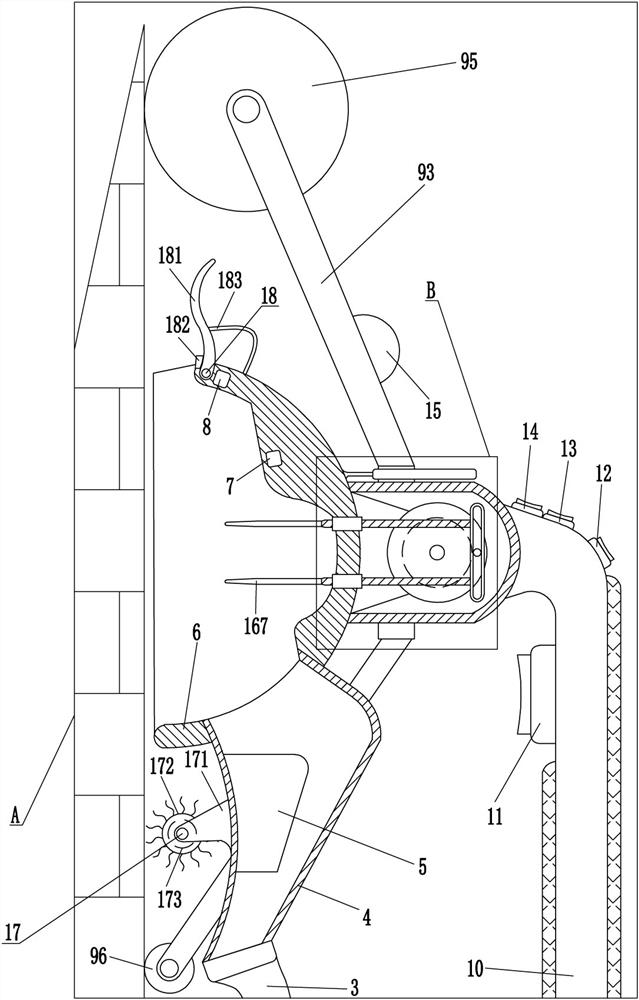

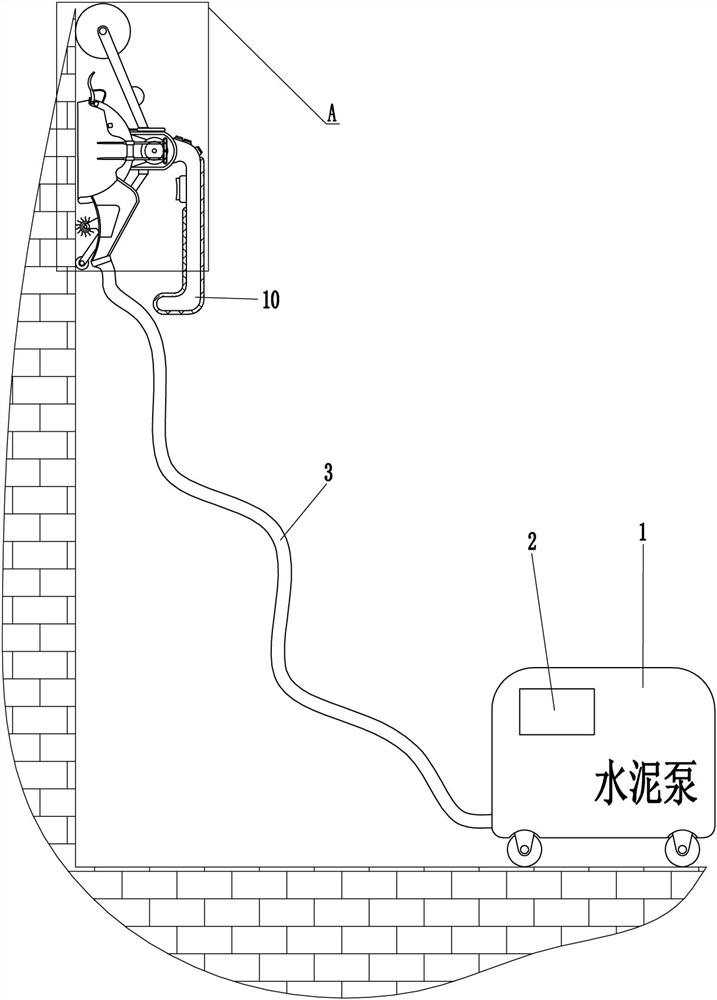

[0023] A rough wall sizing machine, refer to figure 1 , figure 2 and Figure 4 , including cement pump 1, hose 3, buffer pipe 4, diverter plate 5, arc pipe 6, first liquid level sensor 7, second liquid level sensor 8, thickness adjustment mechanism 9 and handle 10, cement pump 1 A hose 3 is connected, and a buffer tube 4 is connected to the hose 3. Eight splitter plates 5 are connected to the left side of the buffer tube 4. The top of the buffer tube 4 is connected to an arc-shaped tube 6. The upper part of the arc-shaped tube 6 is provided with a first The liquid level sensor 7 and the second liquid level sensor 8, the first liquid level sensor 7 is located below the second liquid level sensor 8, the right side of the arc tube 6 is provided with a thickness adjustment mechanism 9, the thickness adjustment mechanism 9 is used to adjust the thickness of the mortar. Thickness, the thickness adjusting mechanism 9 is provided with a handle 10 .

[0024] refer to figure 2 , ...

Embodiment approach 2

[0029] On the basis of Embodiment 1, refer to image 3, also includes extrusion mechanism 16, and extrusion mechanism 16 includes mounting plate 161, first drive motor 162, turntable 163, waist-shaped groove plate 164, guide sleeve 165, guide rod 166, rubber plate 167 and roller 168, The right side of the arc tube 6 is equipped with a mounting plate 161, the mounting plate 161 is located in the square tube 91, the first driving motor 162 is installed on the mounting plate 161, the mounting plate 161 is connected with the first driving motor 162 by bolt connection, the second A turntable 163 is installed on the output shaft of a drive motor 162, the first drive motor 162 is connected with the turntable 163 by a key connection, the roller 168 is connected to the eccentric position on the front side of the turntable 163, and the right side of the arc tube 6 is embedded with a Two guide sleeves 165, guide rods 166 are provided in the guide sleeves 165, the right ends of the two gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com