Heat dissipation type motor

A heat-dissipating, heat-dissipating cover technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problem of poor heat dissipation effect of the motor heat-dissipating structure, and achieve the effect of compact structure, simple installation method and lower production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

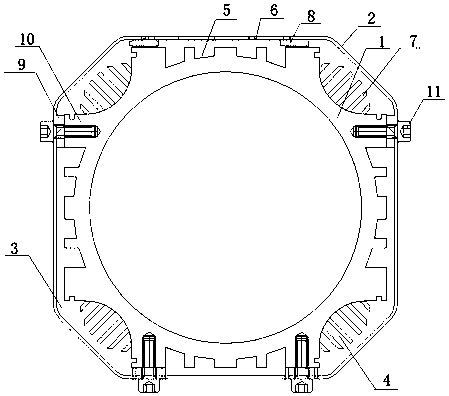

[0021] like figure 1 As shown, a heat dissipation motor includes a motor body 1 and a heat dissipation cover 2 arranged outside the motor body 1 , and the motor body 1 and the heat dissipation cover 2 are fixed by screws 11 . A heat dissipation channel 3 is formed between the heat dissipation cover 2 and the side wall of the motor body 1. The two ends of the heat dissipation channel 3 are open ends. 3 blowing air to dissipate heat from the motor body 1 . A filter is provided at one end of the heat dissipation channel 3 close to the external fan. The filter screen can effectively prevent the dust in the air from accumulating in the heat dissipation channel 3 and affect the heat dissipation effect.

[0022] Among them, the four corners of the motor body 1 are provided with arc-shaped grooves 4 inwardly along the length direction of the motor body 1, and the inside of the arc-shaped groove 4 extends outwards to be provided with 6 cooling fins 7, and the cooling fins 7 The heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com