DC/DC converter for electric vehicle high-power charging device

A technology for high-power charging and electric vehicles, which is applied in the direction of electric vehicle charging technology, electric vehicles, battery circuit devices, etc., can solve the problems of slow charging speed, low boost ratio of boost topology, large device stress, etc., and achieve improved conversion Effects of power converter efficiency, power density improvement, and high voltage gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

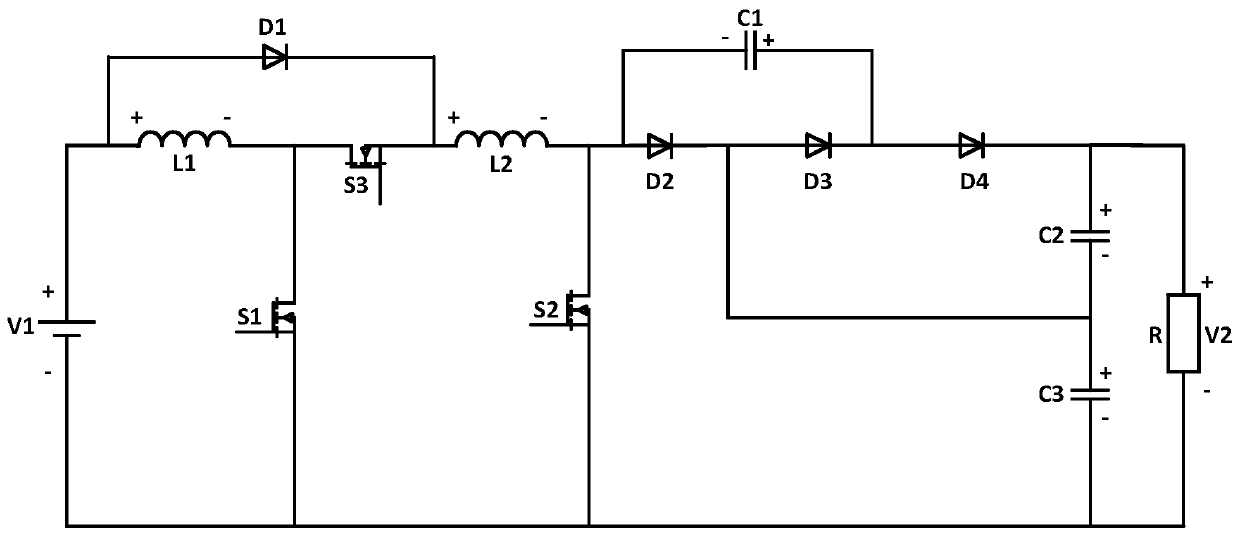

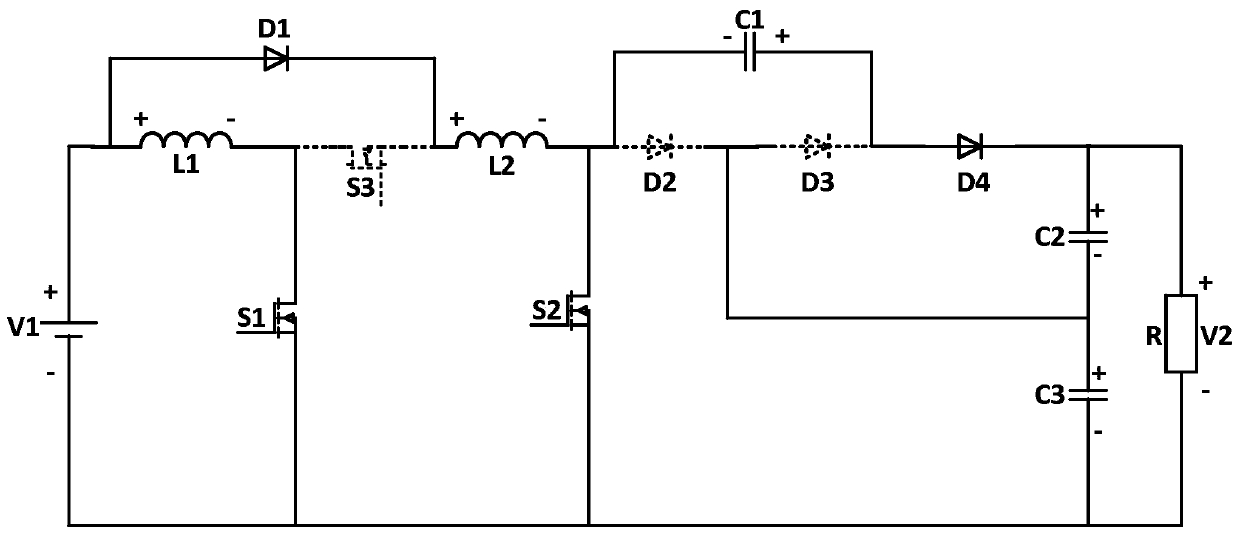

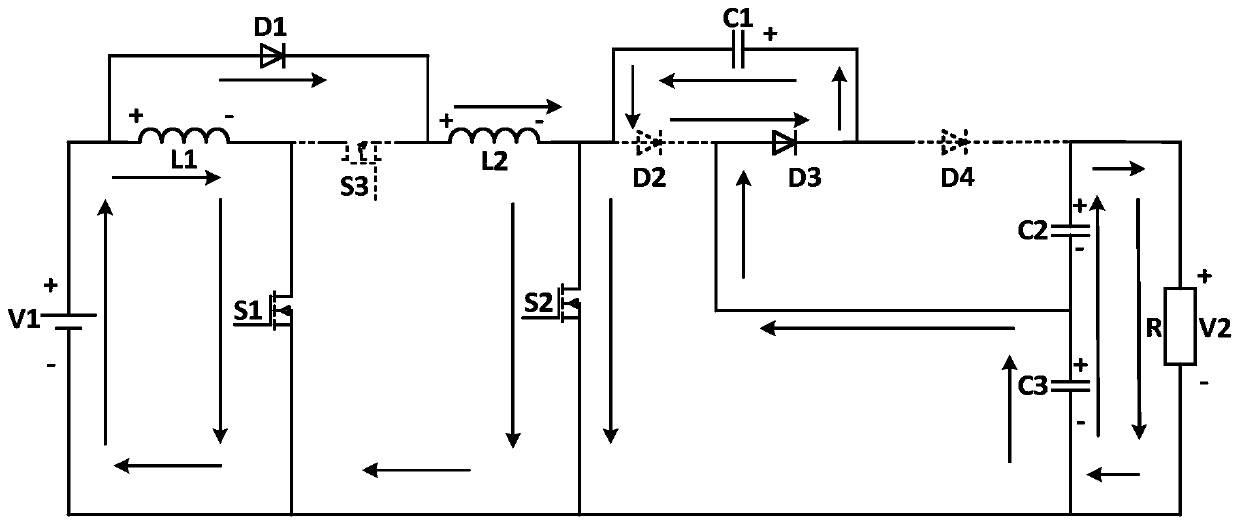

[0035] Specific implementation mode one: the following combination Figure 1 to Figure 6 Describe this embodiment, a DC / DC converter for a high-power charging device for an electric vehicle described in this embodiment includes a DC / DC converter main circuit 1;

[0036] The DC / DC converter main circuit 1 includes a front-end boost structure and a back-end switched capacitor structure;

[0037] The front-end boost structure includes energy storage inductor L1, energy storage inductor L2, diode D1, switching tube S1, switching tube S2 and switching tube S3;

[0038] The back-end switched capacitor structure includes diode D2, diode D3, diode D4, capacitor C1, capacitor C2 and capacitor C3;

[0039] One end of the energy storage inductor L1 is connected to the positive end of the power supply V1; the other end of the energy storage inductor L1 is connected to the drain of the switching tube S1, and the source of the switching tube S1 is connected to the negative end of the sourc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com