Aluminum alloy substrate for magnetic disk, manufacturing method thereof, and magnetic disk using the aluminum alloy substrate for magnetic disk

The technology of an aluminum alloy substrate and manufacturing method, which is applied in the direction of disc carrier manufacturing, magnetic recording, magnetic recording layer, etc., can solve the problems of unobtainable, increased component cost, and different flutter suppression effect, and achieve the effect of excellent flutter characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

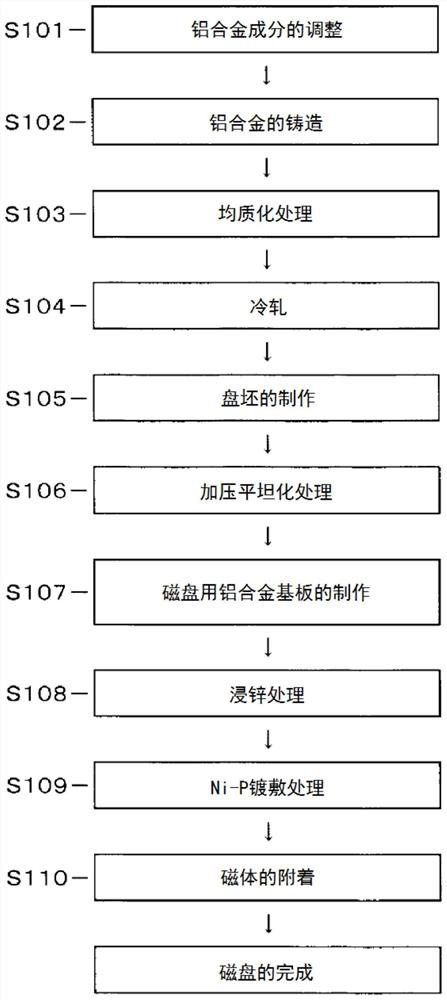

[0085] 6. Preparation and casting of aluminum alloy ingredients

[0086] First, according to the conventional method, the melt having the aluminum alloy material composed of the above components is prepared (step S101). Next, a sheet of an aluminum alloy of about 2.0 to 10.0 mm is cast by a continuous casting method (CC method), the melt of the prepared aluminum alloy material is cast (step S102).

[0087] Here, in the CC method, the melt is supplied to a pair of rollers (or, the beloft cast machine, the Belt Caster), and the block coaster (BLOCK CASTER). The heat is cast directly into the foundation plate of aluminum alloy.

[0088] In the casting of the thin plate of the aluminum alloy using the CC method, the temperature of the cast plate after 1 minute after 1 minute was set to 230 to 350 ° C, preferably 240 to 340 ° C. Further, after 10 minutes of casting, the temperature of the cast plate was set to 150 ° C or more and less than 230 ° C, preferably 160 to 220 ° C. In this wa...

Embodiment

[0100] Next, the present invention will be further described in detail based on the embodiment, but the present invention is not limited thereto.

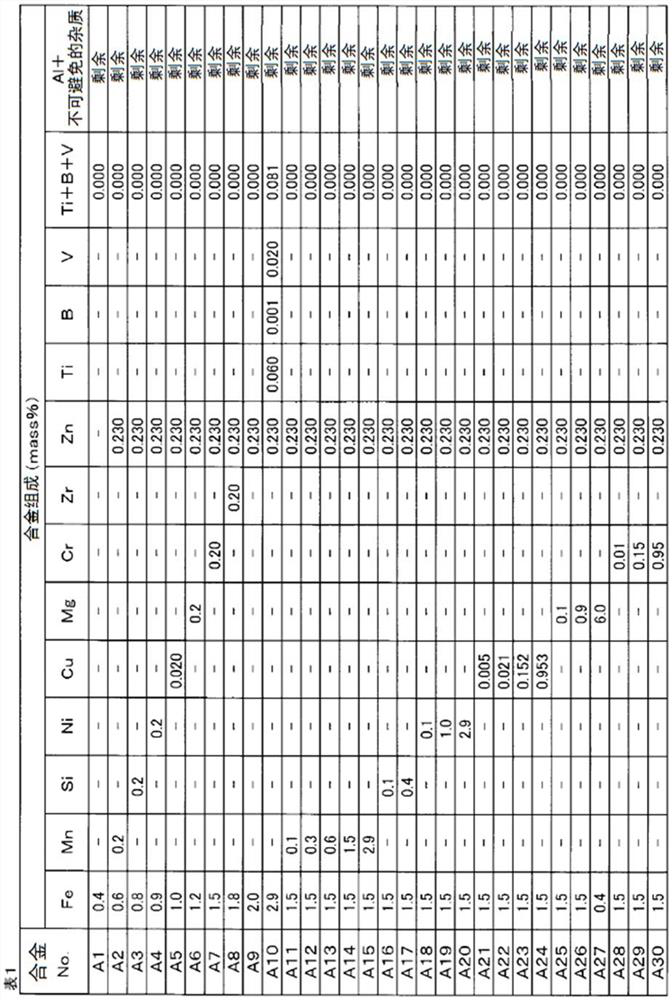

[0101] Each of the alloy materials consisting of the components shown in Tables 1 to T T3 3 is melted according to conventional methods, and the aluminum alloy melt (step S101) is melted. Tables 1 to 3 "-" indicates the measurement of the threshold.

[0102] [Table 1]

[0103]

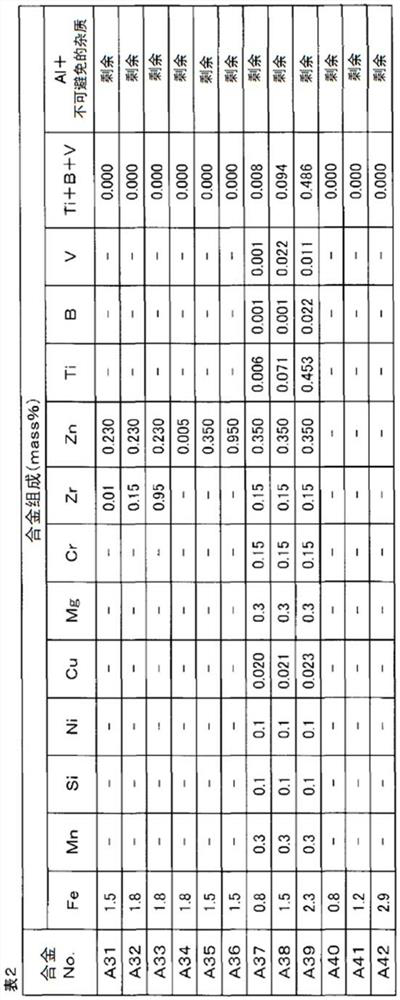

[0104] [Table 2]

[0105]

[0106] [table 3]

[0107]

[0108] Next, the aluminum alloy melt is cast by CC method, and the foundation plate is produced (step S102). In Tables 4 to 6, the thickness of the foundry plate is shown, and the cast plate temperature after the casting after 1 minute is obtained, and the temperature of the cast plate after 10 minutes after casting. Further, a homogenization process is performed for alloys No. A8 to A10 and the AC8 to AC12 (step S103). These homogenization treatment conditions are also shown in Tables 4 to 6.

[010...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grain size | aaaaa | aaaaa |

| directional tensile yield strength | aaaaa | aaaaa |

| directional tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com