A pressurized regeneration method for capturing carbon dioxide in flue gas by alcohol amine method

A technology of carbon dioxide and alcohol amine method, which is applied in the direction of chemical instruments and methods, separation methods, inorganic chemistry, etc., can solve the problems that have not yet been applied, and the total energy consumption of the process is very limited, so as to achieve improved thermal efficiency, high heat utilization efficiency, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

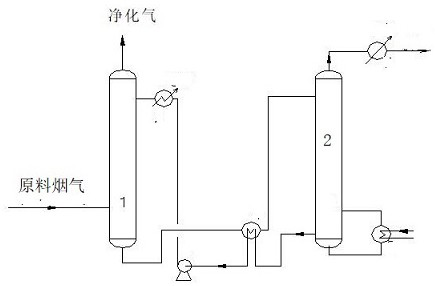

[0032] Example 1 is an existing method, with the following steps:

[0033] Step 1: Using figure 2 The device shown is performed, and only the normal pressure regeneration tower 2 is used. The regenerated solution is directly sent to the absorbent tower 1 after heat exchange, which is a conventional normal pressure regeneration process.

[0034] Step 2: Raw material gas is analog flue gas, CO 2 The content is 10V%, O 2 The content is 6V%, the rest is N 2 , CO 2 The capture rate is 90%, the solution used is 30% a ethanolamine solution, the absorption temperature is 40 ° C, and the absorption pressure is normal pressure.

[0035] Step 3: The pressure regeneration tower 2 tower is 2 kPAg, the tower temperature is 101 ° C, the top temperature is 90 ° C, and the pressure of the heating steam is 0.6 MPa.

[0036] Step 4: Coles obtained by test 2 Unit capture energy consumption is 56.9 kWh / kmol co 2 .

Embodiment 2

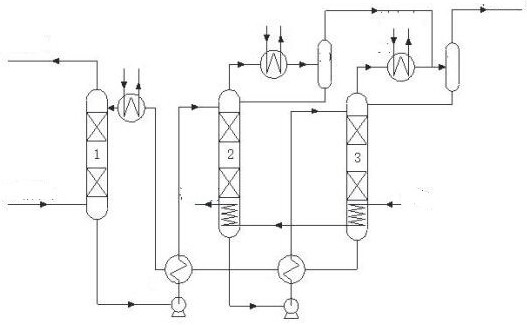

[0038] Step 1: Using figure 1 The device shown is pressurized and regenerated.

[0039] Step 2: Raw material gas is analog flue gas, CO 2 The content is 10V%, O 2 The content is 6V%, the rest is N 2 , CO 2 The capture rate is 90%, the solution used is 30% a ethanolamine solution, the absorption temperature is 40 ° C, and the absorption pressure is normal pressure.

[0040]Step 3: Although the top of the tower of the normal pressure regeneration tower is 2 kPag, the tower temperature is 101 ° C, the top temperature is 90 ° C, the pressurized regeneration tower 3 tower pressure is 180 kPAg, the tower is 132 ° C, tower The top temperature was 120 ° C, and the pressure of heating steam was 0.6 MPa. Always press the regeneration tower 2 and the pressurized regeneration tower 3 regenerate CO 2 The ratio is 0.09: 1.

[0041] Step 4: Coles obtained by test 2 Unit trapping energy consumption of 33.5 kWh / kmol co 2 .

Embodiment 3

[0043] Step 1: Using figure 1 The device shown is pressurized and regenerated.

[0044] Step 2: The raw material gas is an analog flue gas, the CO2 content is 15V%, the O2 content is 5V%, the rest is N2, the CO2 trapping rate is 90%, the solution used is 30 w% of a ethanolamine solution, and the absorption temperature is 40 ° C, the absorption pressure is normal pressure.

[0045] The third step: the pressure regeneration tower 2 column top pressure is 5 kPag, the tower temperature is 102 ° C, the top temperature is 92 ° C, the pressurized regeneration tower 3 tower pressure is 190 kPag, the tower is 133 ° C, tower The top temperature was 121 ° C, and the pressure of heating steam was 0.6 MPa. The ratio of the constant pressure regeneration tower 2 and the pressurized regeneration tower 3 regenerate CO2 is 0.12: 1.

[0046] Step 4: The CO2 unit capture energy consumption is 30.1 kWh / kmol CO2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com