Feed filling device capable of removing feed powder residues

A filling device and feed technology, applied in feed, solid separation, separation of solids from solids by air flow, etc., can solve problems such as prolonging the shelf life of feeds and poor cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

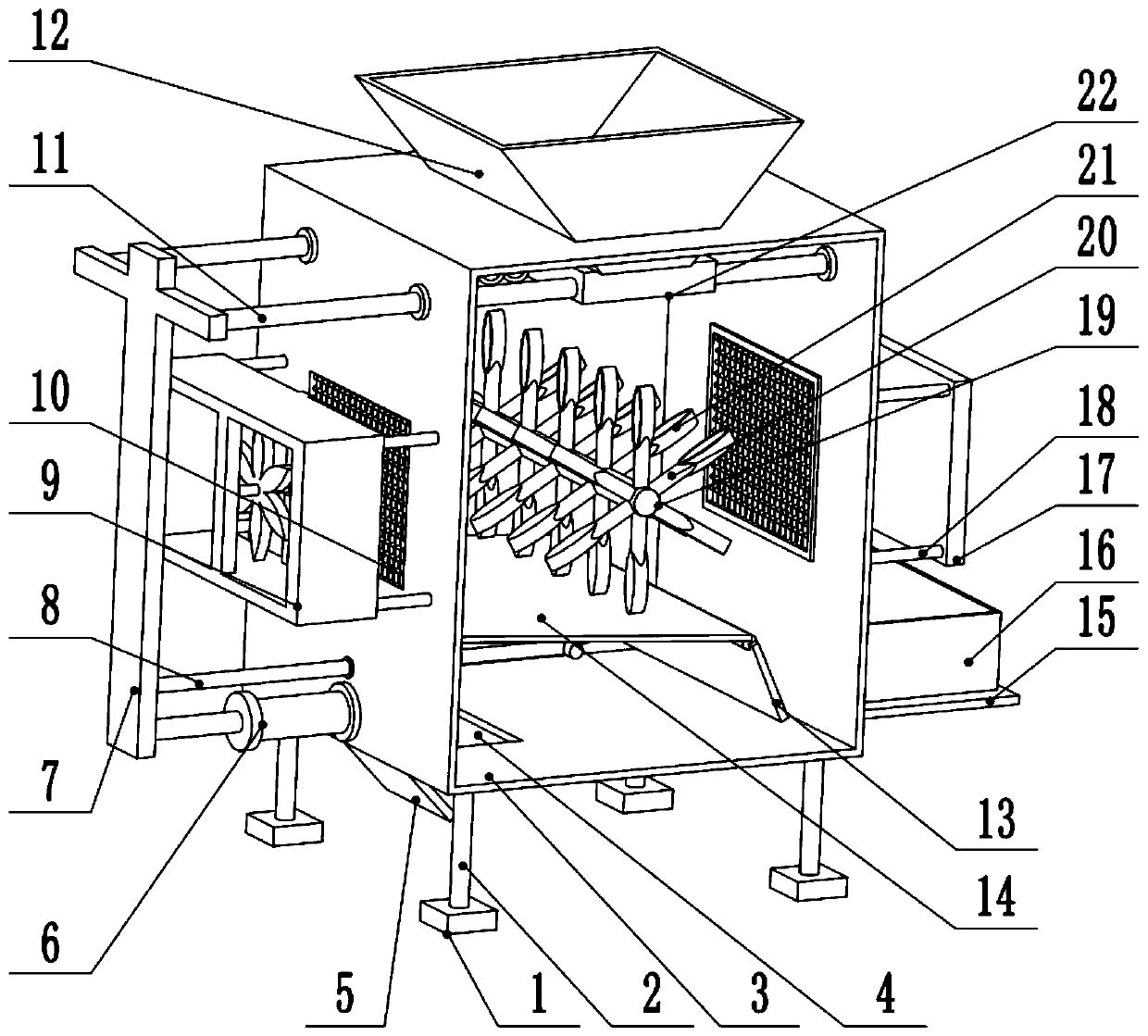

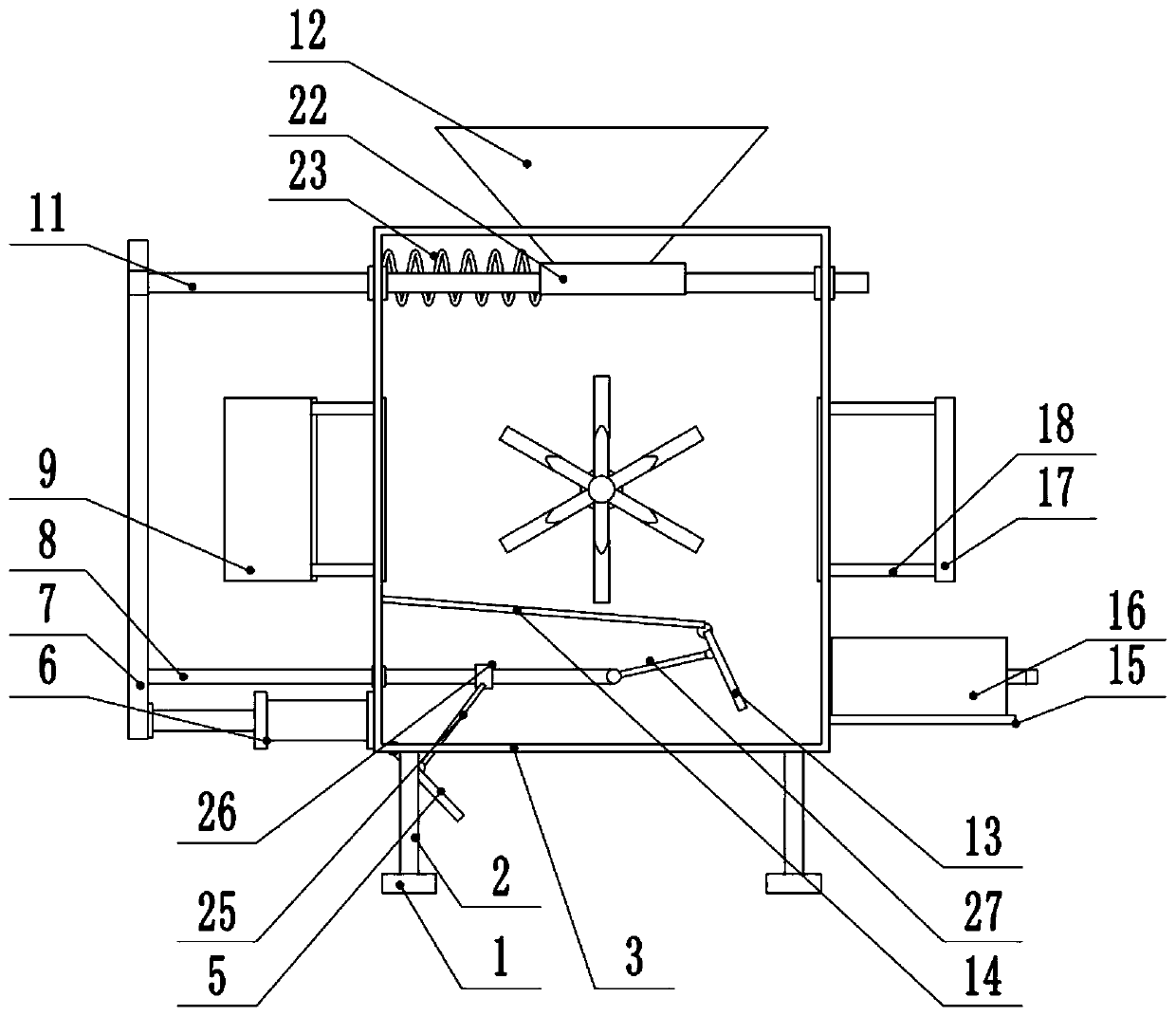

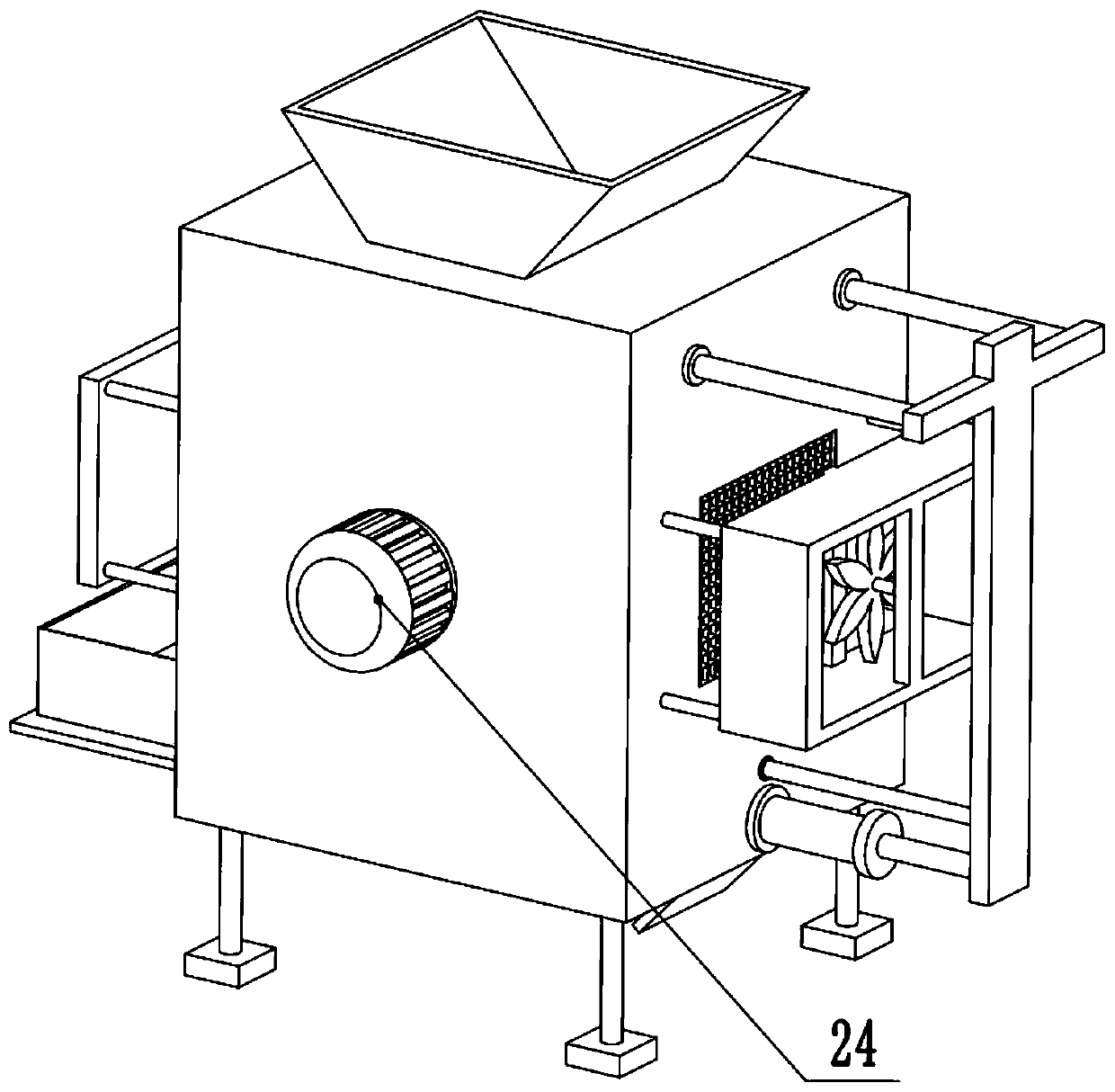

[0023] see Figure 1-3 , a feed filling device capable of removing feed powder and slag, comprising a slag removal box 3, a support column 2 is provided at the bottom of the slag removal box 3, a pad 1 is provided at the lower end of the support column 2, and a bottom left side of the slag removal box 3 The side is provided with a discharge port 4, the left end of the discharge port 4 is rotated to connect with the first baffle plate 5, the top of the slag removal box 3 is provided with a feed port 12, and the lower part of the left side wall of the slag removal box 3 is provided with a cylinder 6. The piston rod of the cylinder 6 is fixedly connected to the lower end of the push plate 7, the lower part of the push plate 7 is connected to the first sliding rod 8, and the middle part of the first sliding rod 8 is slidably connected to the lower part of the left side wall of the slag removal box 3, and the first sliding rod 8 The middle part is provided with a stop block 26, the...

Embodiment 2

[0026] see figure 1 , the other content of this embodiment is the same as that of Embodiment 1, the difference is that: the lower part of the right side wall of the slag removal box 3 is provided with a pallet 15, and the upper part of the pallet 15 is provided with a storage box 16. In order to facilitate the collection of removed powder slag, a storage box 16 is provided at the bottom of the second baffle plate 17. When the powder slag is blown out, the powder slag impacts on the second baffle plate 17, and falls down due to the effect of gravity, and finally falls on the bottom of the second baffle plate 17. In the storage box 16, therefore when the whole device has been working for a period of time, the storage box 16 can be taken out, and the inside of the storage box 16 can be cleaned.

[0027] In the implementation process of the present invention, at first the feed that needs to be processed is put into the slag removal box 3 through the feed port 12, the drive motor 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com