Automatic projection welding process method of robot

A process method and robot technology, applied in manufacturing tools, welding equipment, metal processing, etc., can solve problems such as unstable welding quality, low welding efficiency, and low production efficiency, and achieve automation, high production efficiency, and stable welding quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

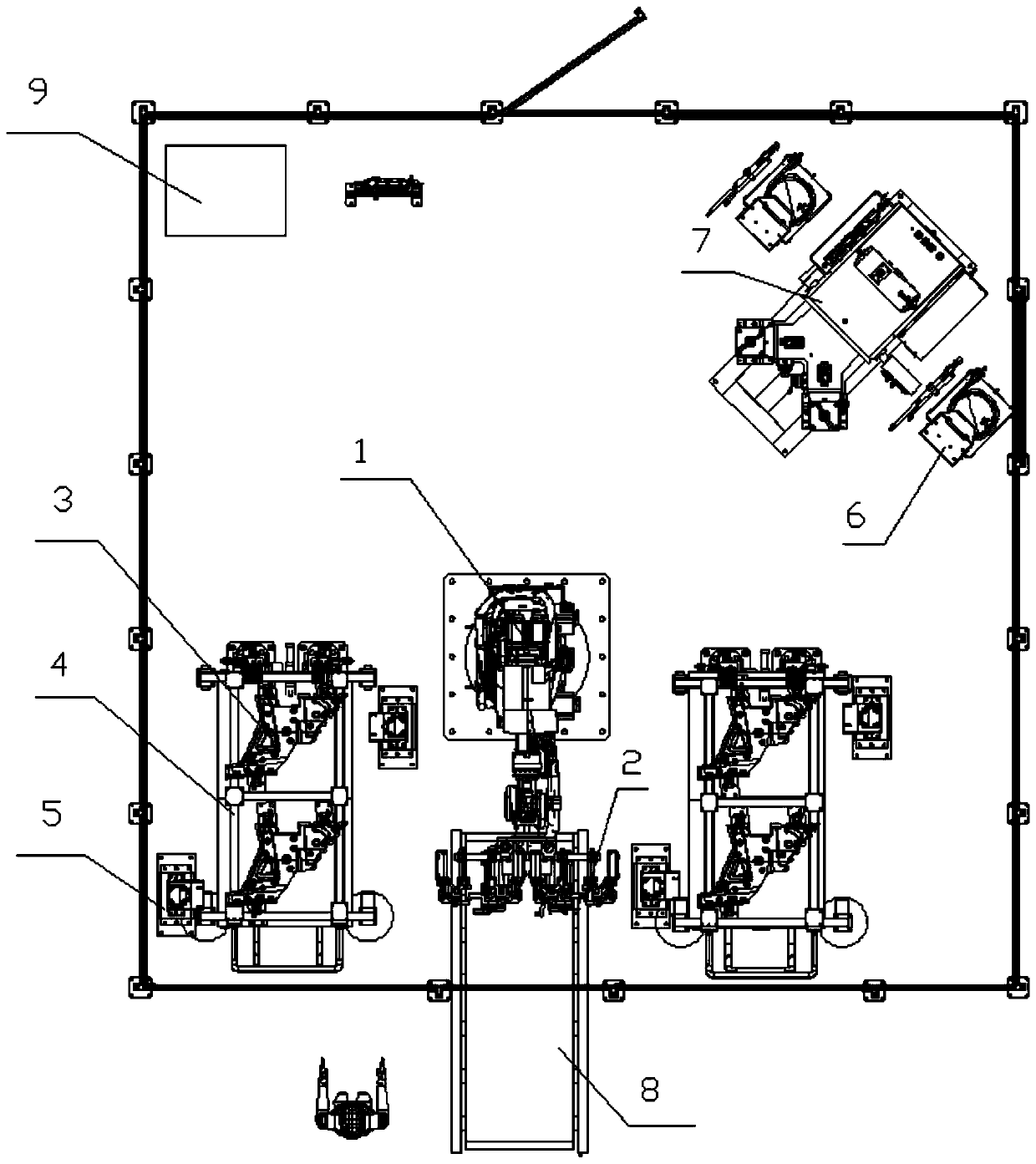

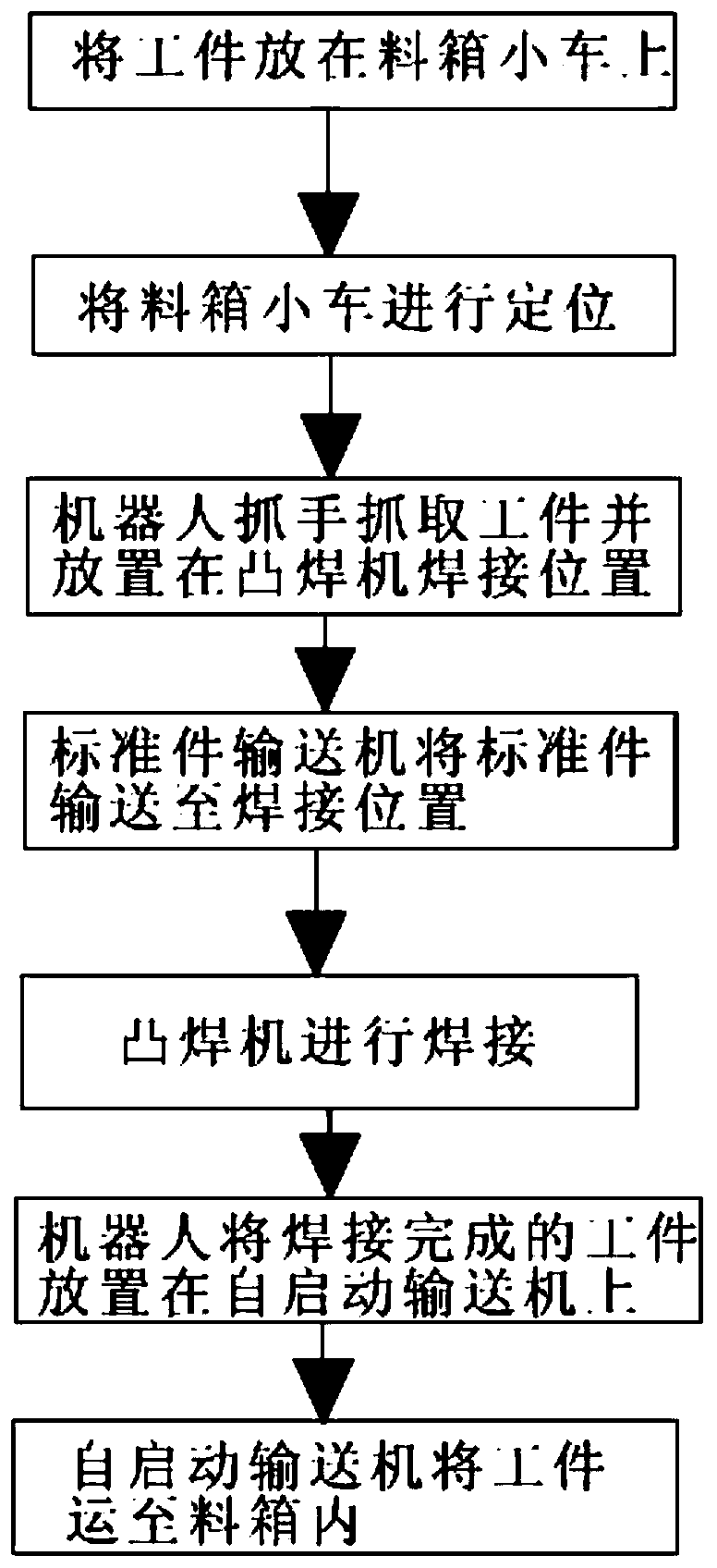

[0020] Robotic automatic projection welding process method, which includes the following process flow:

[0021] In the first step, the workpiece is manually placed on the workpiece fixture 3 of the workpiece fine positioning material box trolley 4;

[0022] In the second step, manually push the precise positioning material box trolley with the workpiece into the material box positioning mechanism 5 for positioning, and PLC 9 controls the material box positioning mechanism to lock the workpiece fixture; the sensor switch is installed on the material box positioning mechanism, When the induction switch detects the position of the trolley, press the confirmation button manually, and the PLC will control the material box positioning mechanism to automatically lock the precise positioning material box trolley.

[0023] In the third step, the PLC controls the robot 1 to grab the workpiece from the workpiece fixture with the gripper 2, and place the workpiece on the positioning mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com