Anti-blocking sludge bin applicable to sludge with water content of 5-65%

A technology of water content and sludge, applied in loading/unloading, container, packaging and other directions, can solve the problems of restricting the stable operation of sludge treatment and disposal projects, difficult to break through sludge storage technology, environmental protection project obstacles, etc. Utilization rate, improving the scope of application, preventing the effect of sludge hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

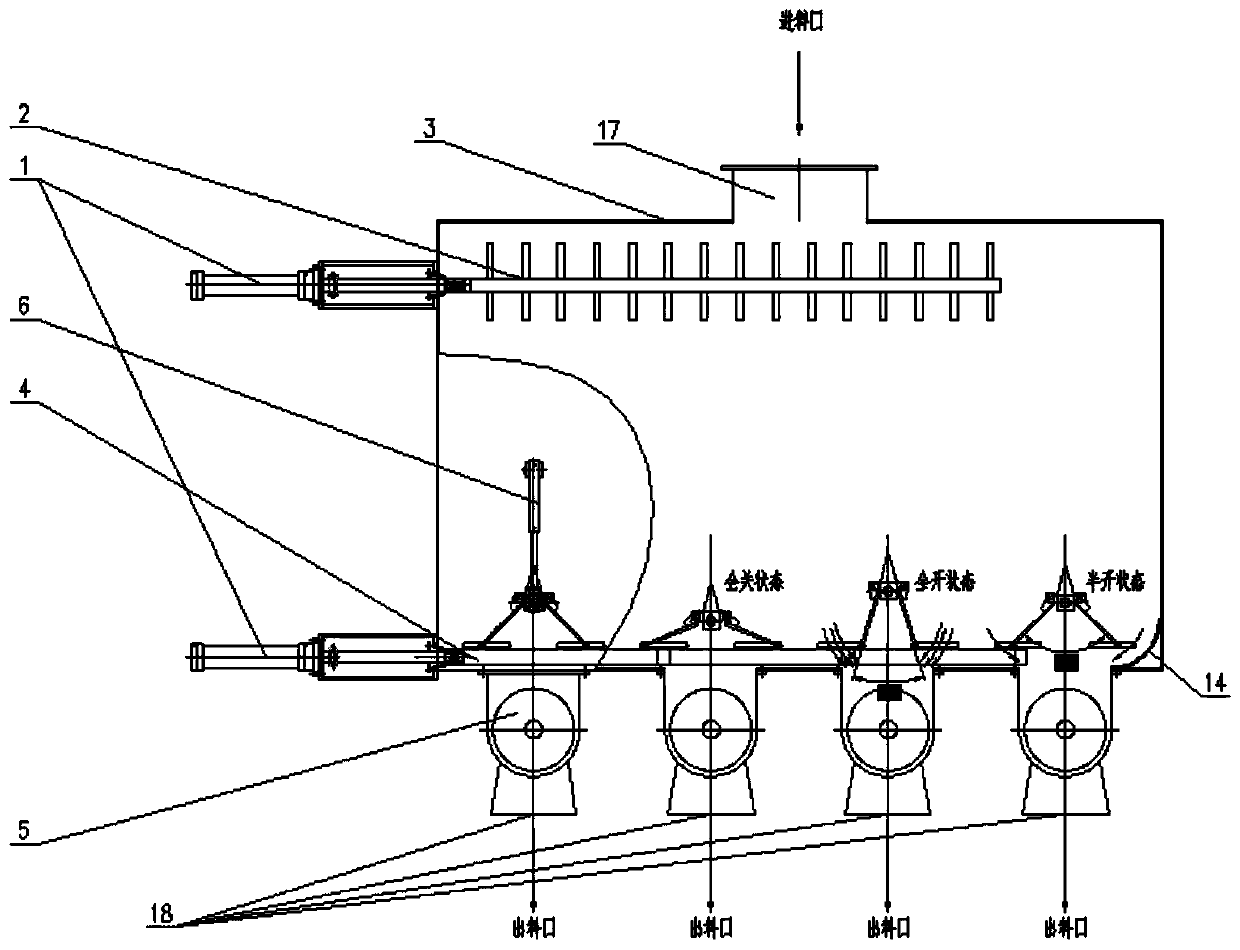

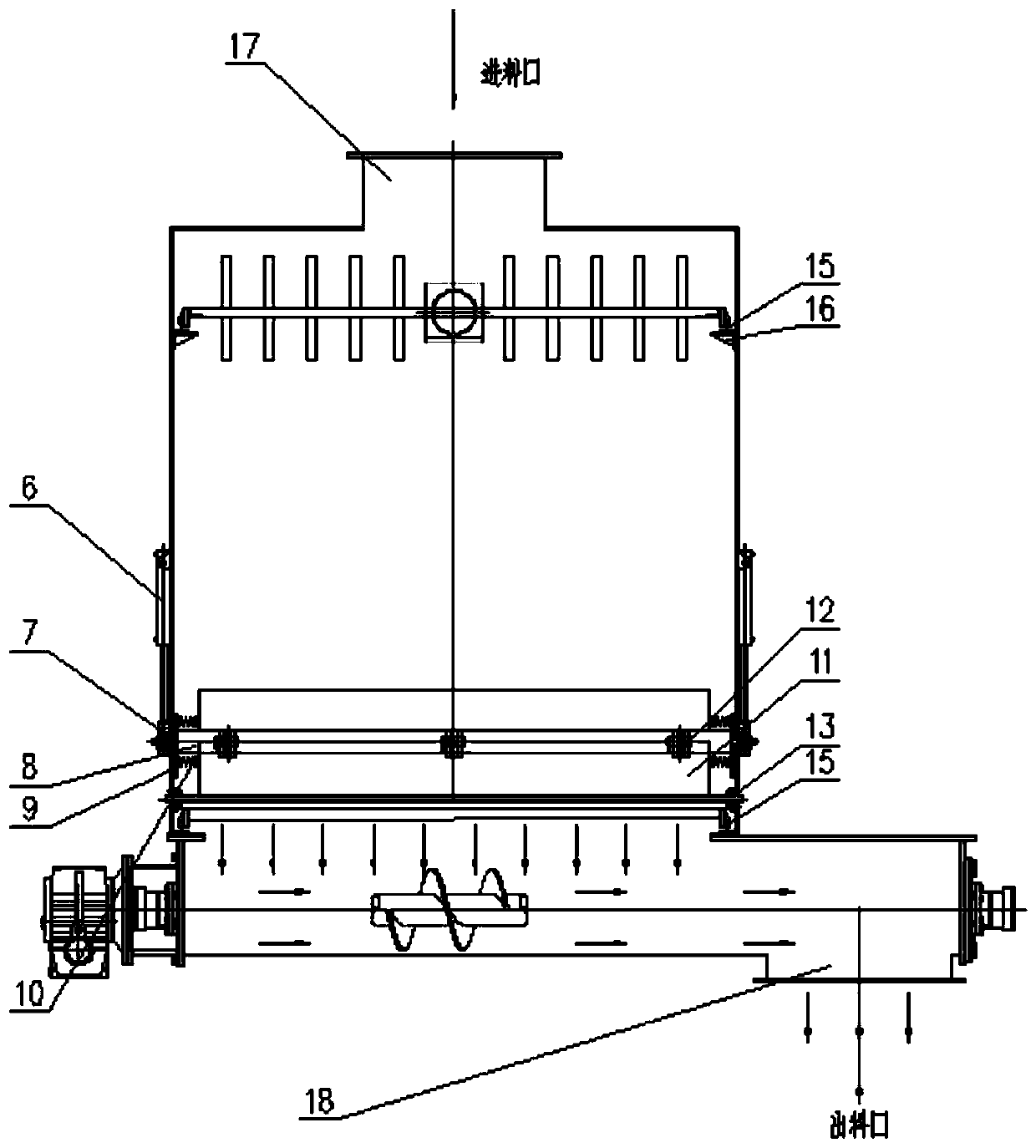

[0027] As shown in the figure, the present invention includes a bin body 3 and a screw conveyor 5 arranged at the bottom of the bin body 3 . The top of the bin body 3 is provided with a feed inlet 17, and the bottom is provided with a sludge outlet. The bin body 3 is provided with a movable sealing plate fixing seat 8, a movable sealing plate 11, a silo carriage 4, and an equalizer 2, and the sludge outlet at the bottom of the bin body 3 communicates with the feeding port of the screw conveyor 5. A circular arc plate 14 is installed at the bottom corner of the bottom of the bin body 3 opposite to the position of the bin carriage 4 .

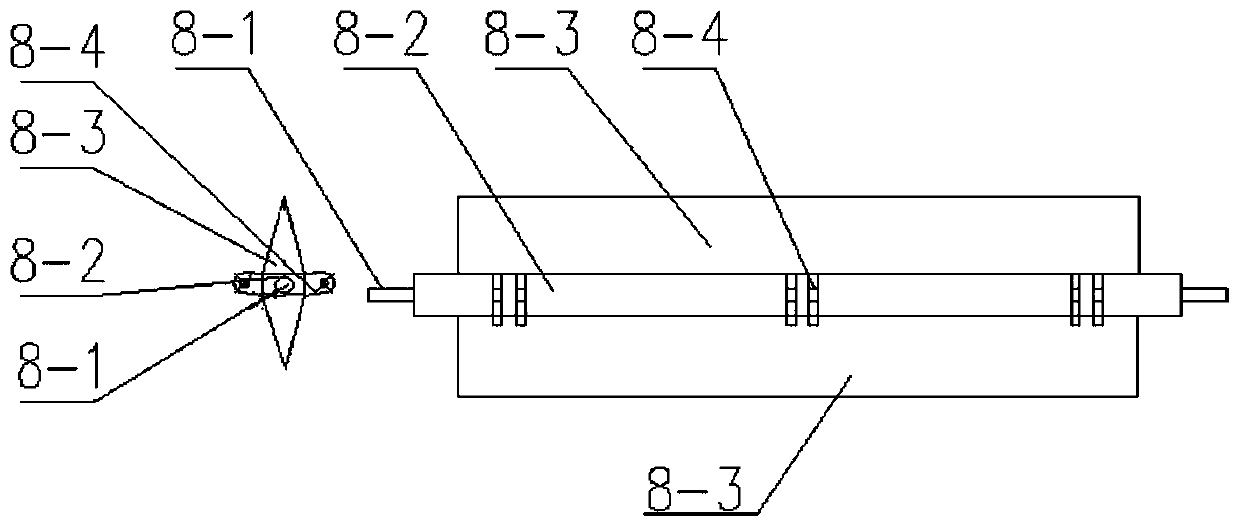

[0028] The movable sealing plate fixing seat 8 includes a shaft head 8-1, a fixing seat body 8-2, two triangular top baffles 8-3, a hinge fixing ear 8-4, and the shaft head 8-1 is welded to the fixing seat body 8-2 Fixing, two triangular top baffles 8-3 are welded and fixed with the upper and lower sides of the fixed seat body 8-2 respectively, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com