Explosive pressing device in detonator production

A technology for pressing powder and detonator, which is applied in the field of medium-pressing device for detonator production, which can solve the problems of excessive pressing, loose pressing, and low yield of detonator, so as to avoid over-extrusion, avoid over-pressing, and improve The effect of quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

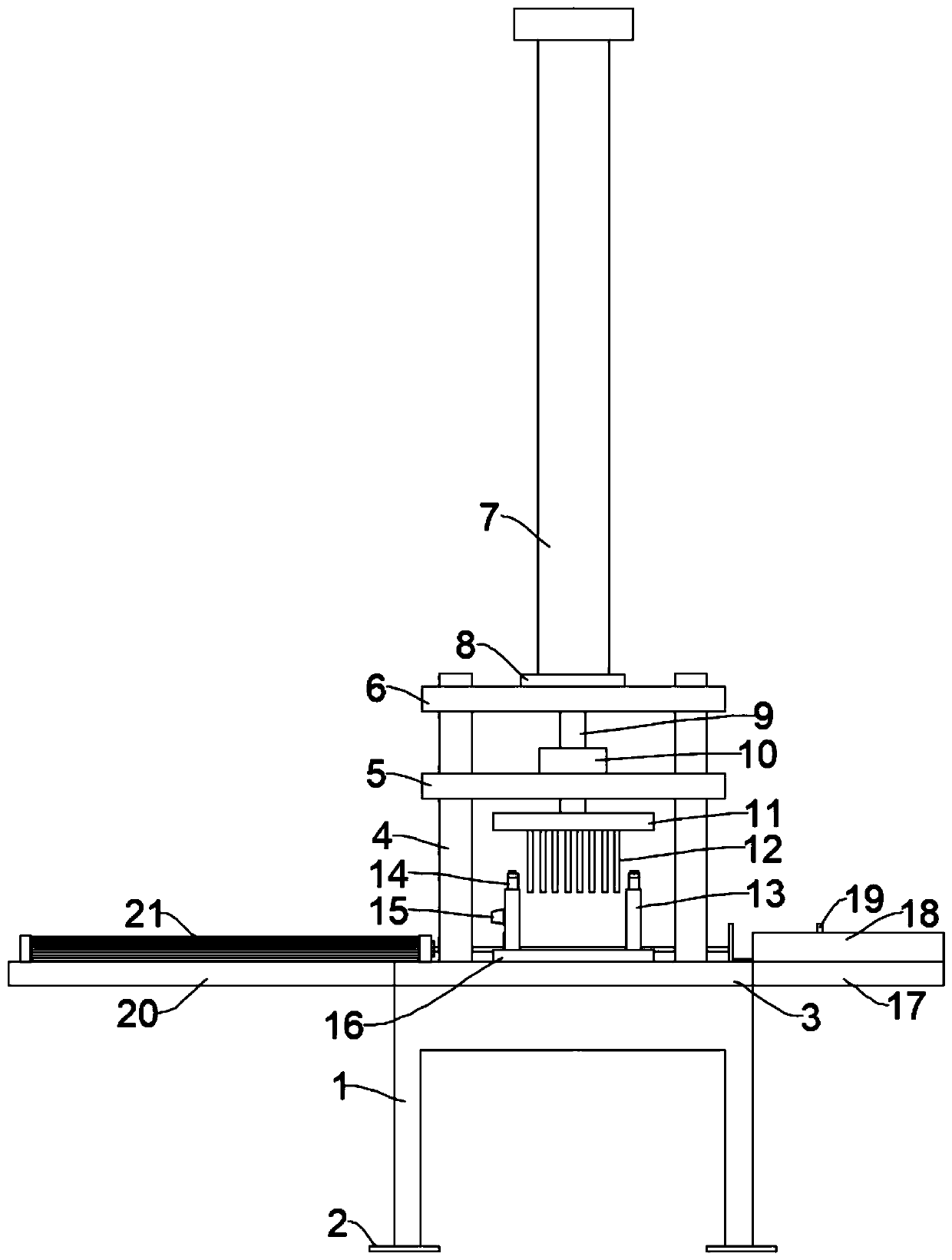

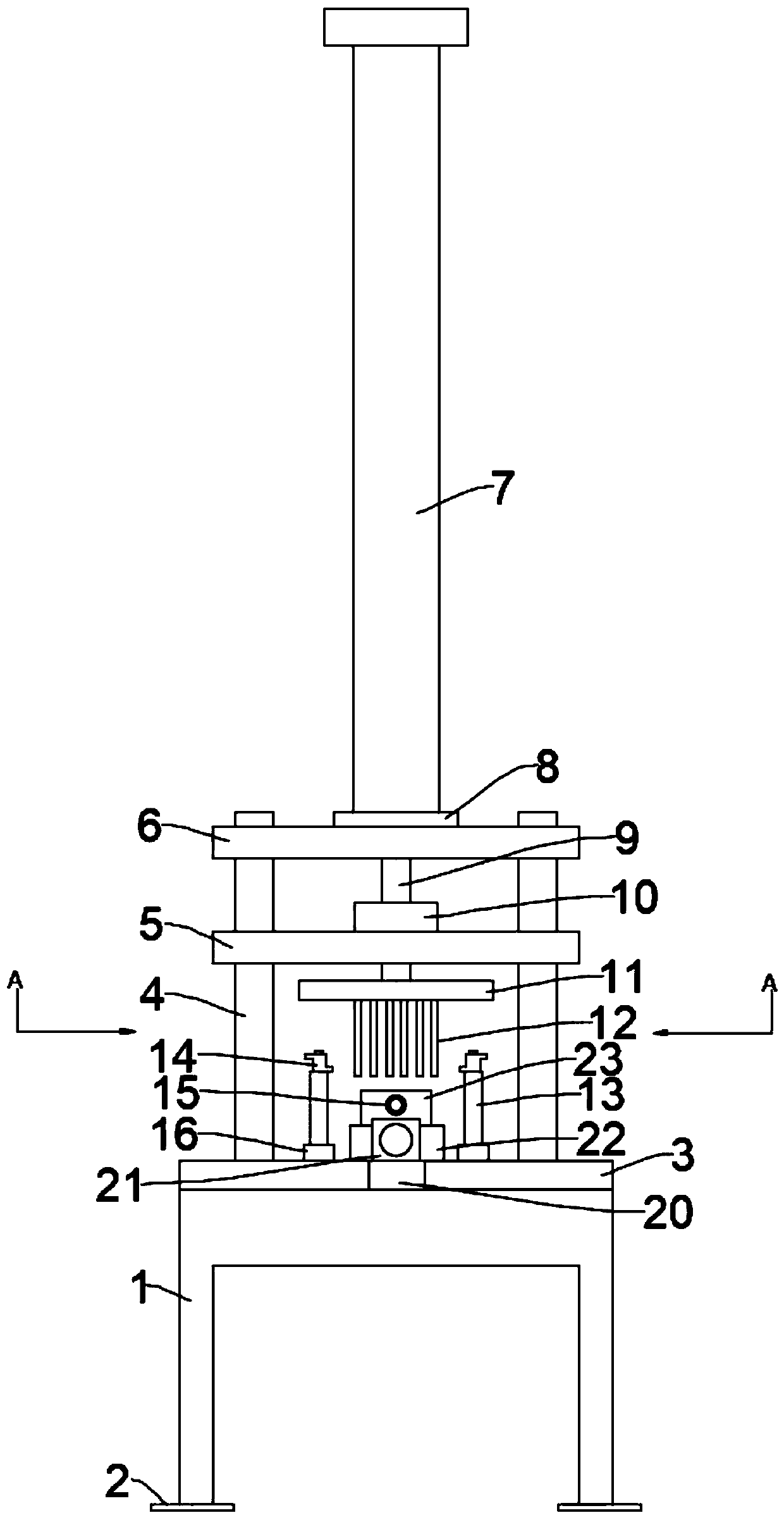

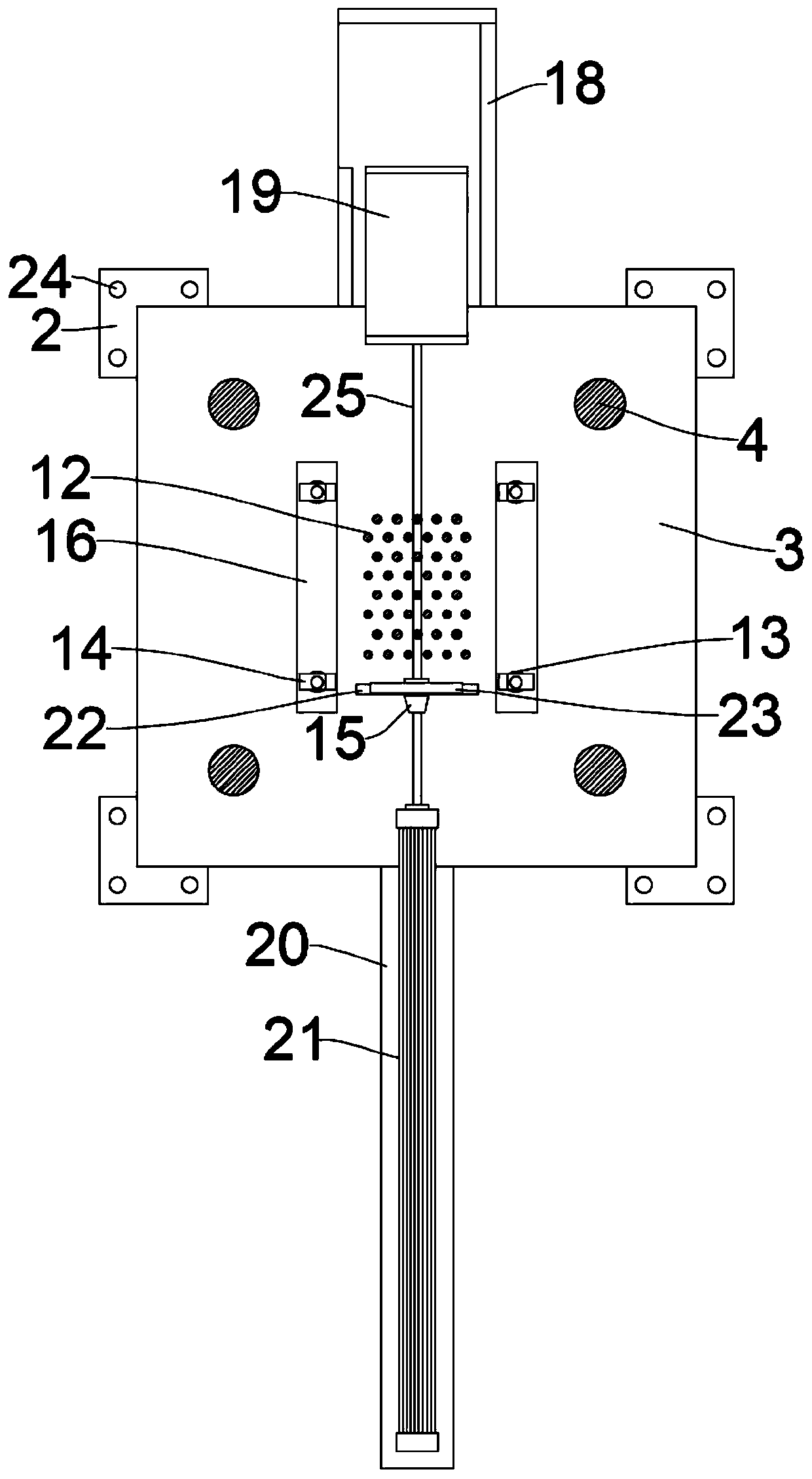

[0034] like Figure 1-Figure 3 As shown, the present embodiment provides a medium-pressure explosive device for detonator production, including a square frame body 1, a fixed platform 6, a pressure column 7, a pressure plate 11, a mold inlet and outlet channel 18 and a manipulator.

[0035] The top of the square frame body 1 is fixedly connected with a bearing platform 3, which is arranged horizontally, wherein the bearing platform 3 is square, and the bearing platform 3 is used for carrying the mold 27 when pressing the medicine. The fixed platform 6 is horizontally arranged on the vertical top of the bearing platform 3, wherein the fixed platform 6 is square, and there are four vertically arranged support rods 4 between the fixed platform 6 and the bearing platform 3, and the four support rods 4 are distributed in the fixed At the four corners of the platform 6 and the bearing platform 3, the bottom ends of the four support rods 4 are fixedly connected with the bearing platf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com