One-step preparation of racemic ketoisoleucine calcium

A technology of calcium racemic ketone isoleucine and one-step method is applied in the field of preparing calcium racemic ketone isoleucine by one-step method, and can solve the problems of ineffective utilization of raw materials, unfavorable atom economy, large negative impact on the environment, and the like, Achieving the effect of highly competitive market advantages, convenient large-scale production and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Preparation of the wet product of the crude calcium isoleucine racemate

[0034] Add 100g hydantoin, 90g butanone, 85g monoethanolamine, 300g water to the reaction tank, heat up to 72°C, react for 7.5 hours, cool down to 30~40°C after the reaction, add 165g sodium hydroxide, continue to heat up to 83°C , the reaction time is 7.5 hours, cool down to 30~40 ℃, add hydrochloric acid to adjust pH value to 3~4, then add 120g calcium chloride, cool down 20~30 ℃, grow crystal for 2~3 hours, centrifuge to obtain racemic ketone Crude calcium isoleucine wet product, wet weight 182g.

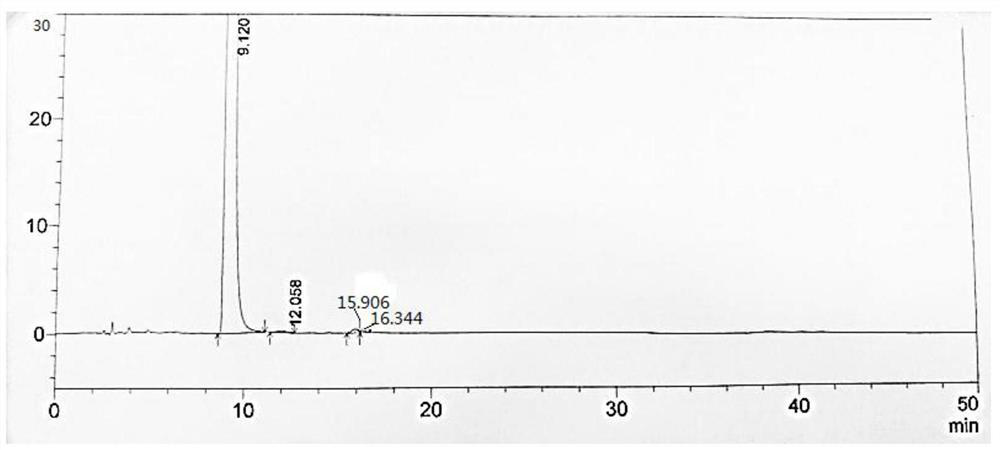

[0035] 2. Preparation of Calcium Racemone Isoleucine

[0036] In the reaction tank, add 182g of crude wet product of racemic isoleucine calcium, add 500g of ethanol, heat up to 60~70℃ to dissolve, add 5g of activated carbon to decolorize after dissolving, filter, and slowly cool the filtrate to 25~35℃ for thermal insulation analysis Crystallize for 2-3 hours, filter, and wash the filter cake wit...

Embodiment 2

[0038] 1. Preparation of the wet product of the crude calcium isoleucine racemate

[0039] Add 100g hydantoin, 80g butanone, 80g monoethanolamine, 300g water to the reaction tank, heat up to 68°C, react for 7.0 hours, cool down to 30~40°C after the reaction, add 150g sodium hydroxide, continue to heat up to 80°C , the reaction time is 7.0 hours, cool down to 30~40 ℃, add hydrochloric acid to adjust pH value to 3~4, then add 115g calcium chloride, cool down 20~30 ℃, grow crystal for 2~3 hours, centrifuge to obtain racemic ketone Crude calcium isoleucine wet product, wet weight 173g.

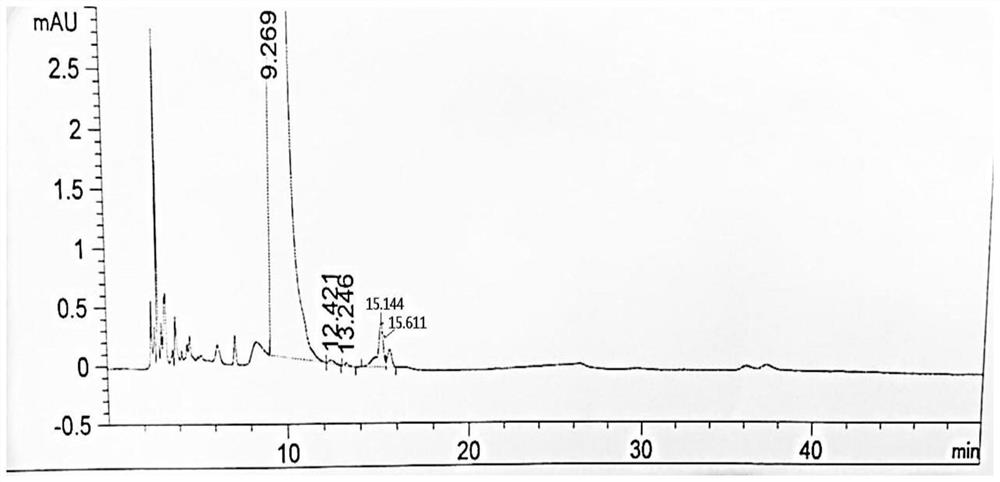

[0040] 2. Preparation of Calcium Racemone Isoleucine

[0041] In the reaction tank, add 173 g of the wet product of the crude calcium isoleucine racemate, add 500 g of ethanol, heat up to 60-70 °C to dissolve, add 5 g of activated carbon to decolorize after the solution is clear, filter, and slowly cool the filtrate to 25-35 °C for thermal insulation analysis. Crystallize for 2-3 hours, filter, ...

Embodiment 3

[0043] 1. Preparation of the wet product of the crude calcium isoleucine racemate

[0044] Add 100g hydantoin, 90g butanone, 80g monoethanolamine, 300g water to the reaction tank, heat up to 75°C, react for 8.0 hours, cool down to 30~40°C after the reaction, add 160g sodium hydroxide, continue to heat up to 80°C , the reaction time is 7.0 hours, cool down to 30~40 ℃, add hydrochloric acid to adjust pH value to 3~4, then add 120g calcium chloride, cool down 20~30 ℃, grow crystal for 2~3 hours, centrifuge to obtain racemic ketone Crude calcium isoleucine wet product, wet weight 177g.

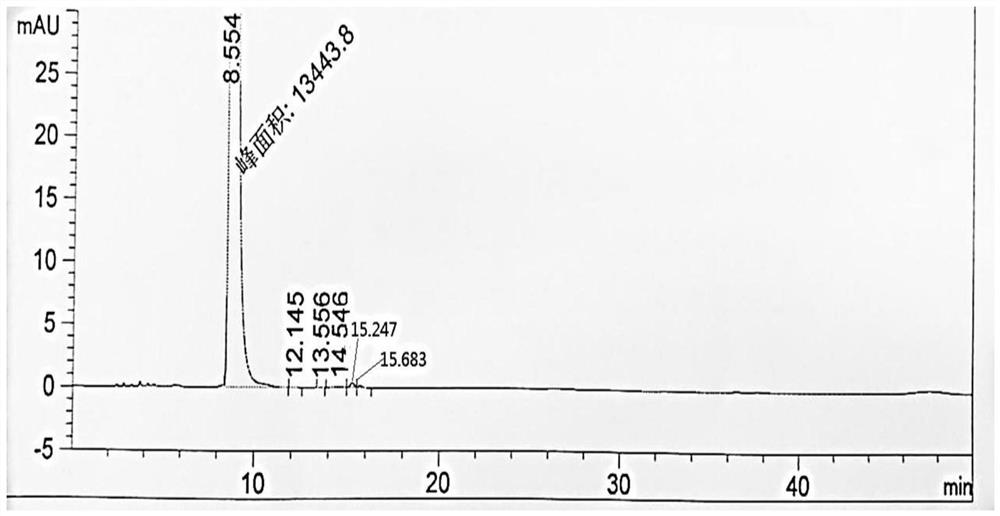

[0045] 2. Preparation of Calcium Racemone Isoleucine

[0046] In the reaction tank, add 177g of the crude wet product of racemic ketone isoleucine calcium, add 500g of ethanol, heat up to 60-70°C to dissolve, add 5g of activated carbon to decolorize after the solution is clear, filter, and the filtrate is slowly cooled to 25-35°C for thermal insulation analysis. Crystallize for 2-3 hours, filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com