Electric arc furnace sand filling device

An electric arc furnace and sand filling technology, which is applied in the field of electric arc furnace steelmaking, can solve the problems of high operating environment temperature, high dust noise pollution, high labor intensity, etc., and achieve the effect of increasing service life, improving work efficiency, and flexible and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

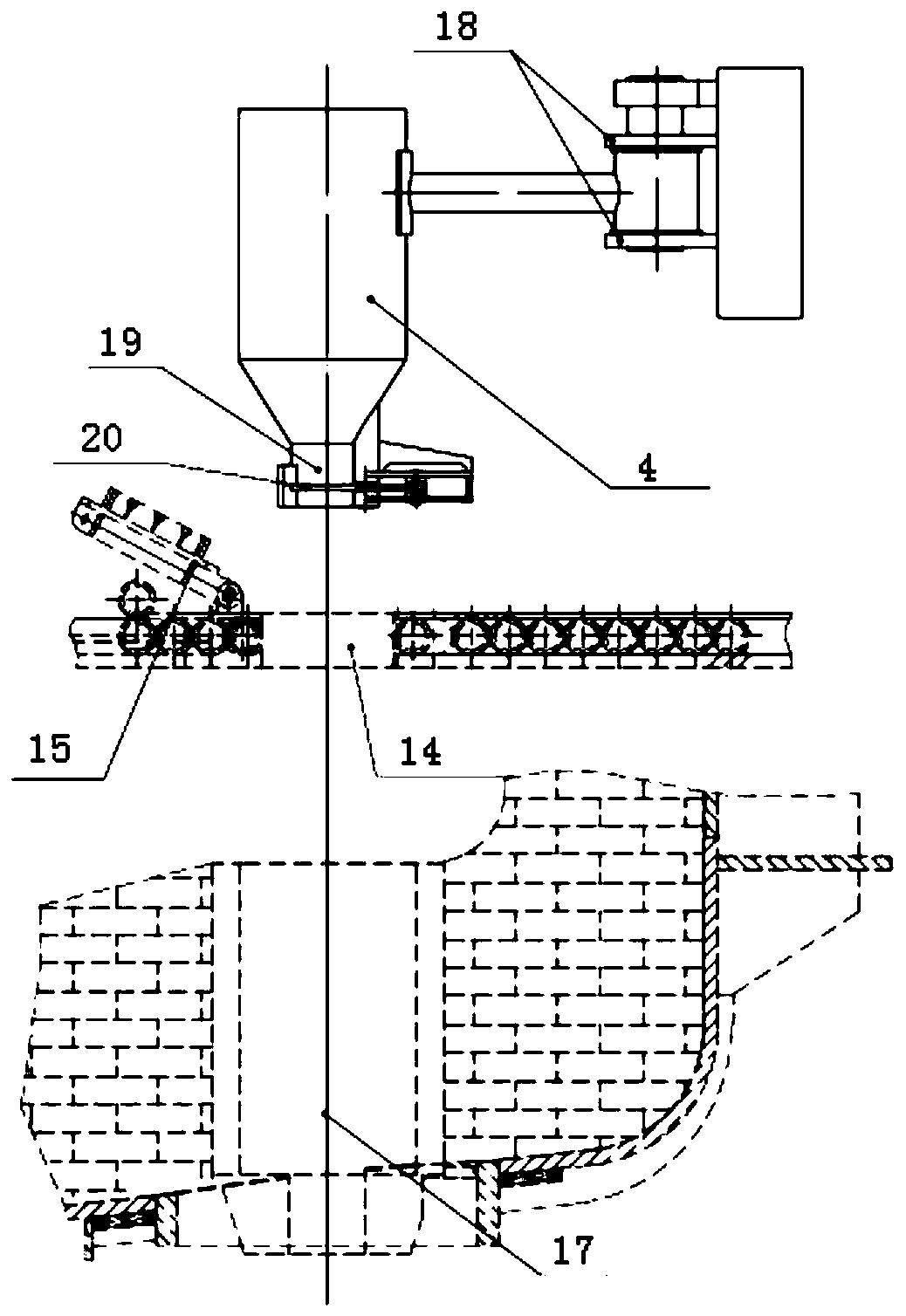

[0024] Such as figure 1 As shown, an electric arc furnace sand filling device is installed directly above the sand filling port 14 in the eccentric area of the furnace shell 1; a sand filling port 14 for filling magnesia is designed on the upper water cooling plate in the eccentric area of the furnace shell 1, and the sand filling port 14 is designed in the normal state. The sand port 14 is to cover with the sand filling port cover 15 to prevent heat loss in the furnace and outside air from entering the furnace. The vertically downward area of the sand filling port 14 is a tapping channel 16 , and a tapping port 17 is designed at the bottom of the eccentric bottom furnace shell 1 , through which molten steel meeting the smelting standard flows out.

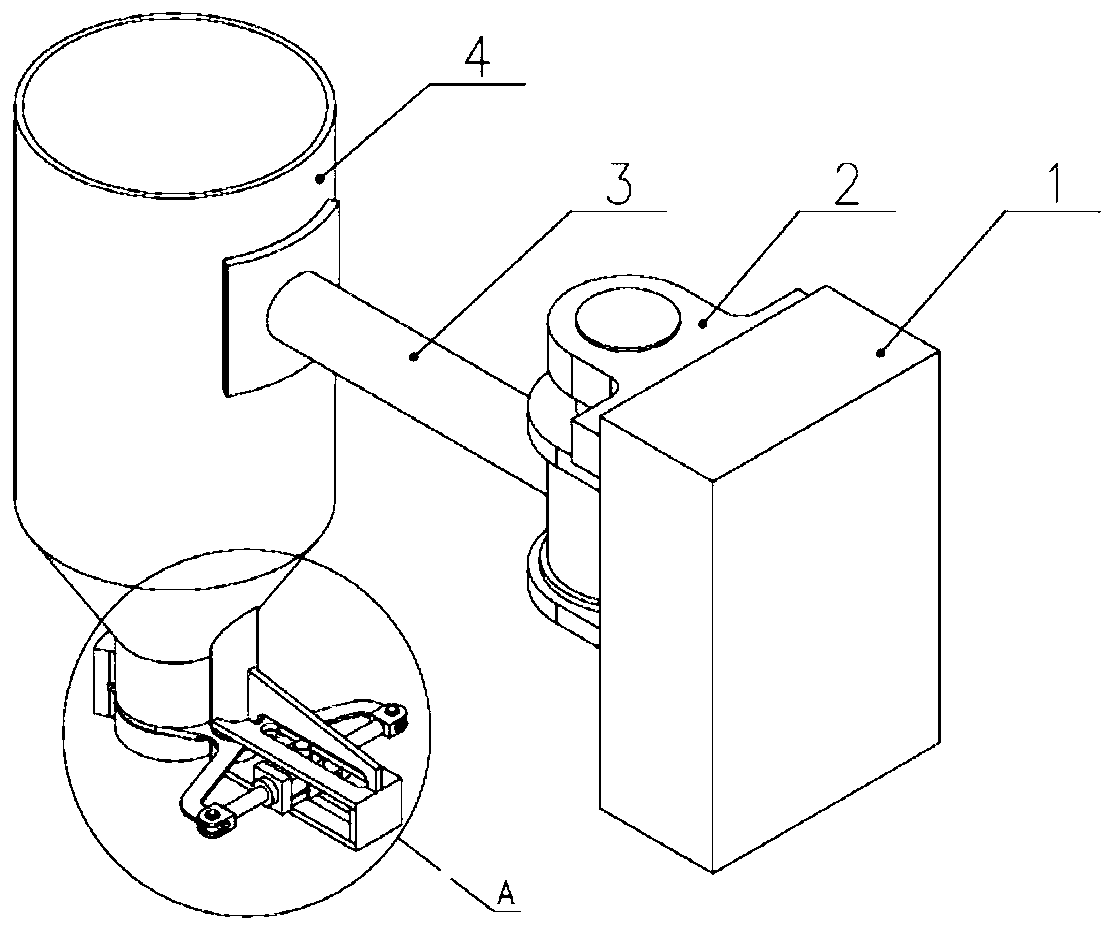

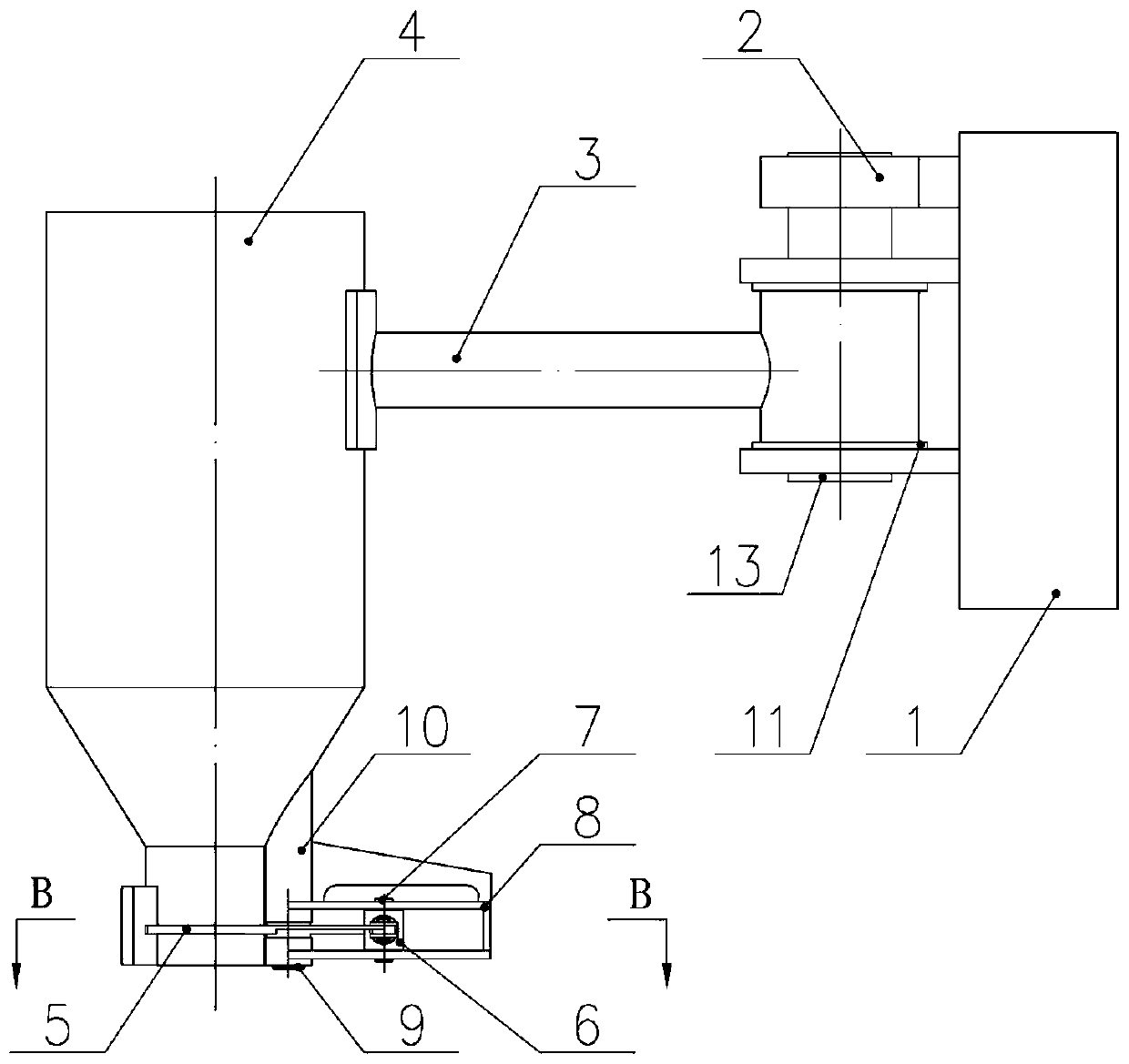

[0025] Such as figure 2 with im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com