Sintered iron-containing material, sintered composition, sintered ore and preparation method thereof

A technology of sinter and composition, which is applied in the field of blast furnace smelting, can solve the problems of sinter droplet performance index influence, suspended material, and influence on blast furnace conditions, etc., and achieve good droplet performance, cost reduction, and consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055]In a fourth aspect, the present application provides a method of preparing a sintering ore comprising: sintering the sintering composition provided by the second aspect embodiment. The sintered composition was mixed with a sintering composition prior to sintering treatment.

[0056]In some possible embodiments, the preparation method of the sintered order includes:

[0057]Mix: Wet the sintered iron-containing water, optionally, in a cylindrical mixer, with a wetting material to obtain a wet material.

[0058]Granulation: Mix the moisturizing material, fuel, and flux, optionally, in the secondary cylindrical mixer, the granulation time is 2.5 to 3.5 min to give the particulate material.

[0059]Cloth: Even the particulate material is uniform on the sinter trolley, optionally, control the thickness of the sintered material layer within 750 mm.

[0060]Ignition: Control the sintering machine under negative pressure, optionally, the ignition temperature of the sintering machine is 1000-1100 ° C...

Embodiment 1

[0066]A method of preparing a sintered order, including:

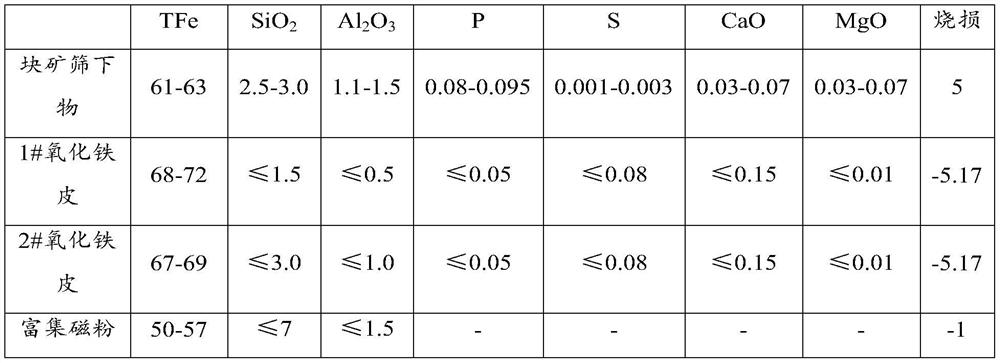

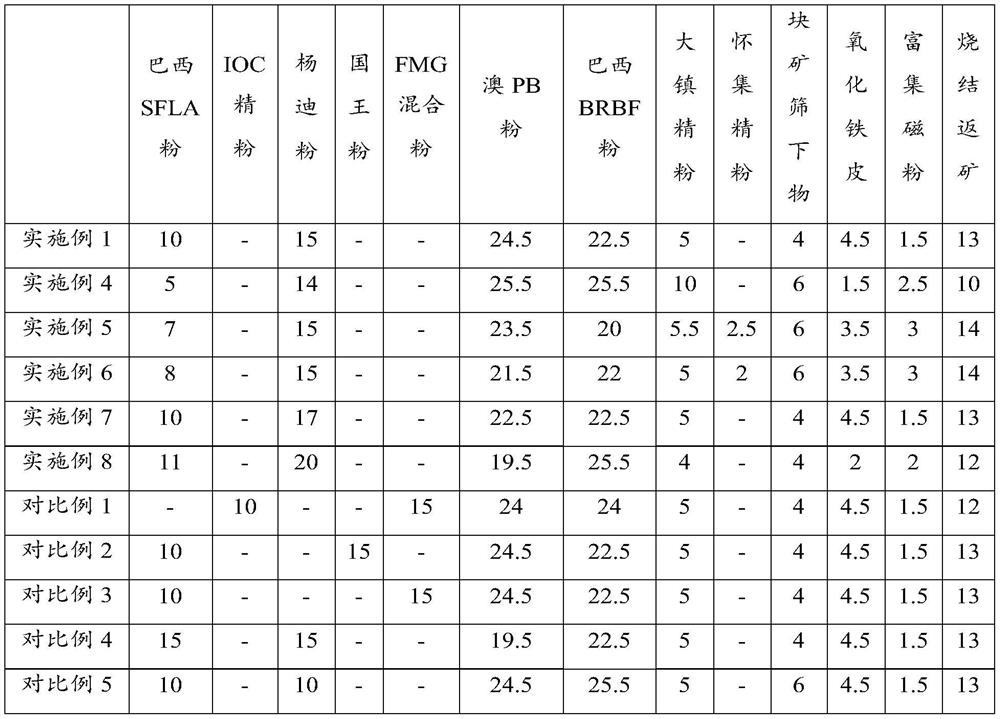

[0067]S1. Fabricated, sintered iron-containing raw materials, as shown in Table 3, the comparison of the sintering composition, as shown in Table 4.

[0068]S2. In a cylindrical mixer, a sintered iron containing water is wetted, and the water distribution is 7.3% to obtain a wetting material.

[0069]S3. In the secondary cylindrical mixer, the moisturizing material, fuel and flux are mixed with granulation, and the granulation time is 3 min to give granule material.

[0070]S4. Even the particulate material is evenly matched on a sintering machine trolley, and the thickness control of the sintered material is controlled in 750 mm.

[0071]S5. Control the ignition of the sintering machine, the ignition temperature of the sintering machine is 1050 ° C, the ignition time is 1.5 min, and the ignition negative pressure is 8000 Pa.

[0072]S6. After the sintering machine is complete, the fuel in the raw material begins to combust, and the sintering...

Embodiment 2

[0076]A method of preparing a sintered order, including:

[0077]S1. It is equipped with a raw material, which is the same as that of the iron-containing raw material ratio and the sintering composition, as in Example 1.

[0078]S2. In a cylindrical mixer, the sintered iron is wetted, and the water distribution is 6.7% to obtain a wetting material.

[0079]S3. In the secondary cylindrical mixer, the moisturizing material, fuel and flux are mixed, and the granulation time is 2.5 min to obtain particulate materials.

[0080]S4. Even the particulate material is evenly matched on a sintering machine trolley, and the thickness control of the sintered material is controlled in 750 mm.

[0081]S5. Control the ignition of the sintering machine, the ignition temperature of the sintering machine is 1000 ° C, the ignition time is 1.5 min, and the ignition negative pressure is 8000 Pa.

[0082]S6. After the sintering machine is complete, the fuel in the raw material begins to combust, and the sintering negative ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com