Preparation method of LDHs (Layered Double Hydroxides) composite flame retardant

A composite flame retardant and coupling agent technology, which is applied in the field of inorganic flame retardants, can solve the problems of reducing the flame retardant efficiency of flame retardants, difficult to meet thermal stability, and limiting the scope of use, etc., to achieve droplet suppression performance, good Application prospect, excellent effect of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Weigh 46.2g of magnesium nitrate and 22.6g of aluminum nitrate and dissolve in 300mL of water to form a metal salt solution; another weigh 24g of sodium hydroxide and dissolve in 500mL of water to form lye; at 25°C, slowly dissolve the prepared lye adding the metal salt solution to adjust the pH value of the metal salt solution to 10 to prepare a precursor slurry.

[0032] 2. Add 3.5g of APP with a degree of polymerization of 200 to 500mL of the above precursor slurry, stir and react at 25°C for 3 hours, then let stand for 12 hours, filter, wash and dry to obtain APP-LDHs powder.

[0033] 3. Weigh 40 parts of APP-LDHs powder prepared in step 2, and weigh 8 parts of monopentaerythritol, 1 part of γ-aminopropyltriethoxysilane, 20 parts of absolute ethanol, 80 parts of grinding balls, and put In the ball mill tank, ball mill at a ball mill speed of 250 rpm for 8 hours and then dry to obtain a composite flame retardant.

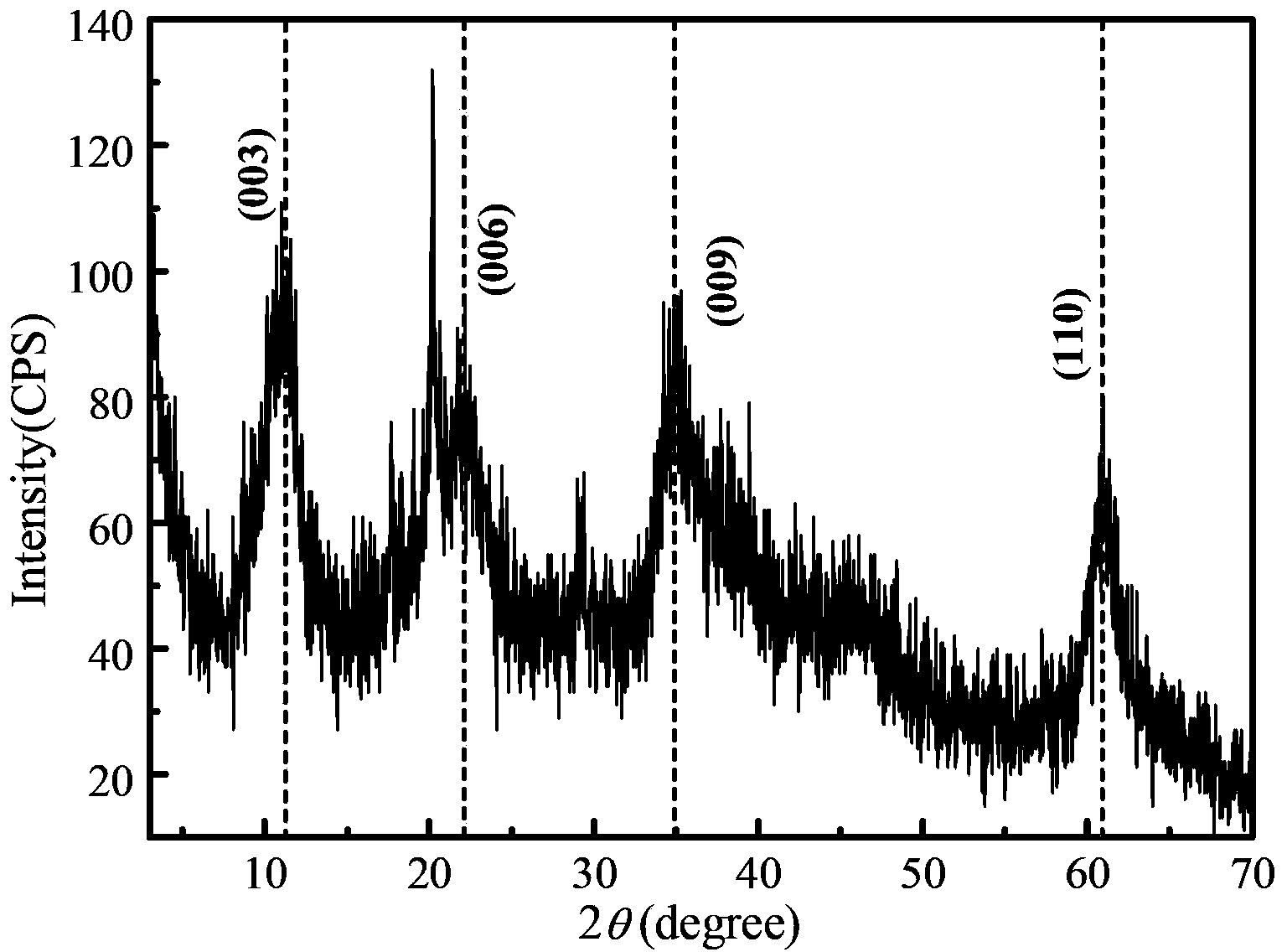

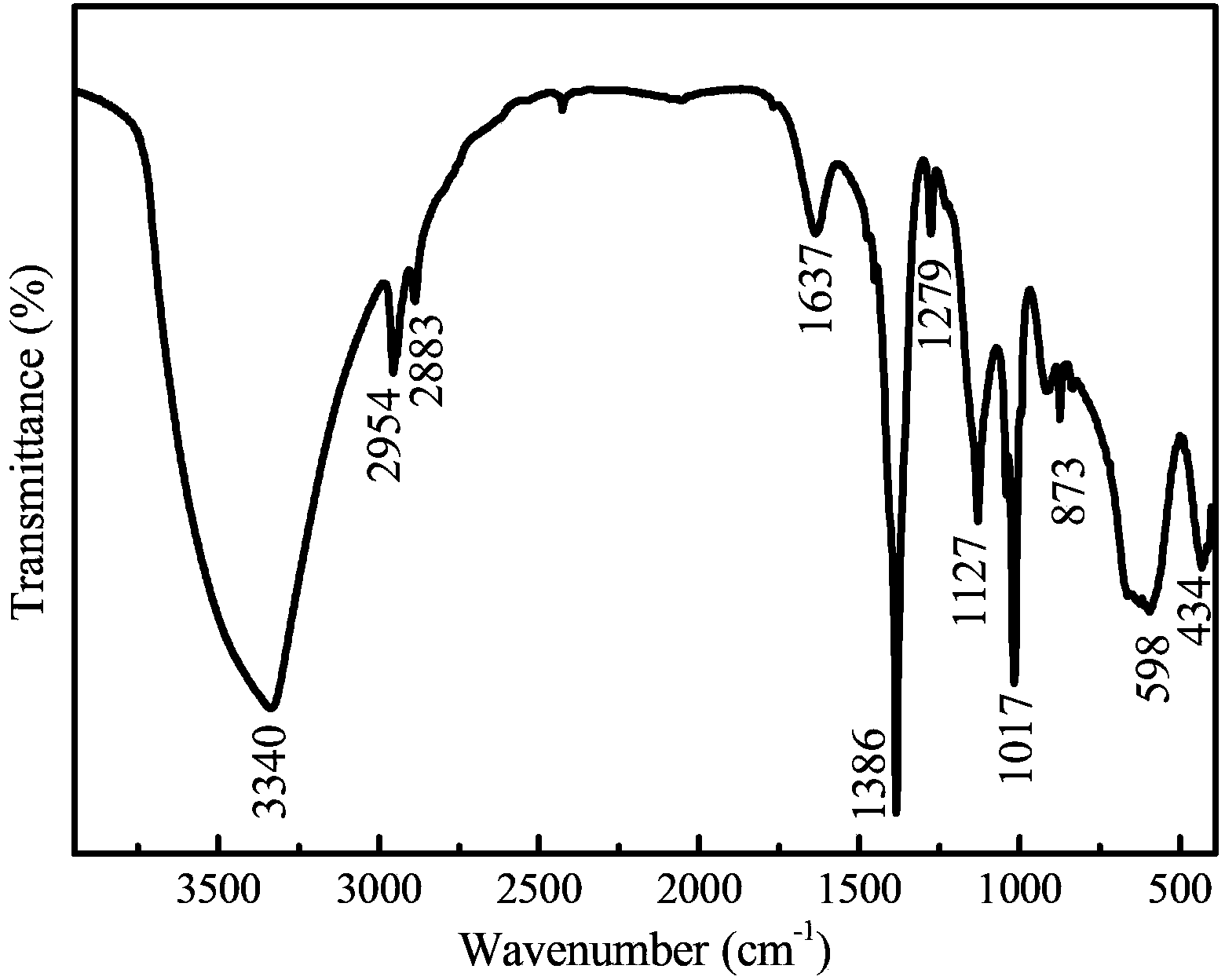

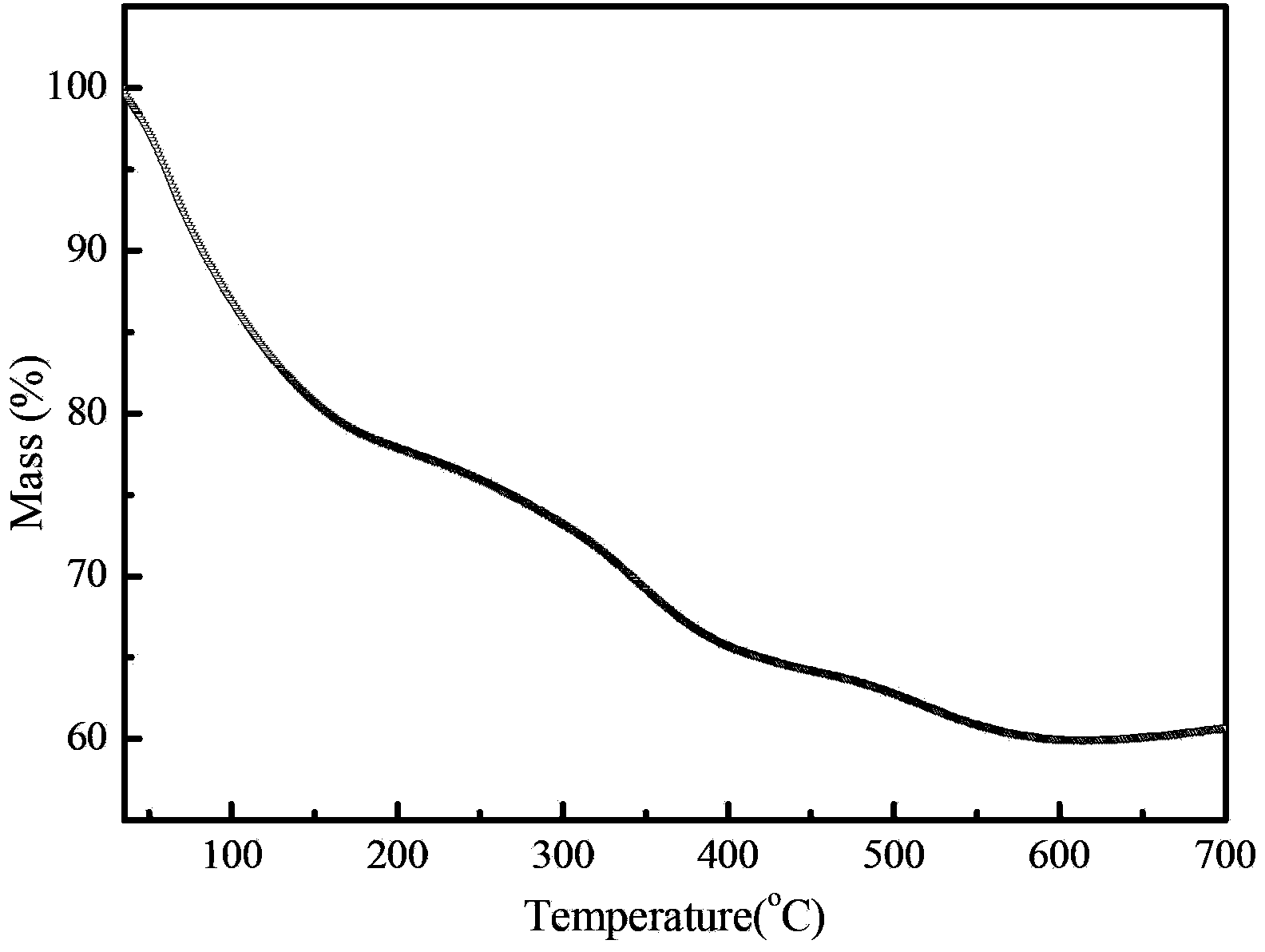

[0034] figure 1 It is the XRD pattern of the pr...

Embodiment 2

[0037] 1. Dissolve 20.5g of magnesium chloride and 24.8g of aluminum sulfate in 300mL of water to form a metal salt solution; take another 22g of sodium hydroxide and 17g of sodium carbonate and dissolve in 500mL of water to form a lye; The lye is slowly added into the metal salt solution, and the pH value of the metal salt solution is adjusted to 11 to prepare a precursor slurry.

[0038] 2. Add 5.0 g of APP with a degree of polymerization of 400 to 500 mL of the above precursor slurry, stir and react at 35°C for 2.5 hours, then let stand for 11.5 hours, filter, wash and dry to obtain APP-LDHs powder.

[0039] 3. Weigh 39 parts of APP-LDHs powder prepared in step 2, and weigh 9 parts of dipentaerythritol, 0.5 parts of γ-aminopropyltriethoxysilane, 22 parts of absolute ethanol, 85 parts of grinding balls, and put In the ball milling tank, the ball milling speed is 300 rpm for 6 hours and then dried to obtain the composite flame retardant.

[0040] Mix the composite flame reta...

Embodiment 3

[0042] 1. Weigh 35.7g of zinc nitrate, 30.2g of magnesium nitrate and 44.2g of aluminum nitrate and dissolve in 500mL of water to form a metal salt solution; another weigh 30g of sodium hydroxide and dissolve in 500mL of water, add 200mL of ammonia water (mass concentration 28%) as lye; at 45°C, slowly add the prepared lye into the metal salt solution, adjust the pH of the metal salt solution to 11, and prepare the precursor slurry.

[0043] 2. Add 8g of APP with a polymerization degree of 100 to 500mL of the above precursor slurry, stir and react at 45°C for 2.5 hours, then let stand for 24 hours, filter, wash and dry to obtain APP-LDHs powder.

[0044] 3. Weigh 65 parts of APP-LDHs powder prepared in step 2, and weigh 10 parts of β-cyclodextrin, 0.8 parts of isopropyl tris(dioctyl pyrophosphate acyloxy) titanate, 30 parts of industrial alcohol Parts, 150 parts of balls, put into a ball mill jar, mill at a milling speed of 520 rpm for 5 hours and then dry to obtain a composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com