Method for preparing pellet ores by adding ilmenite into high-chromium vanadium titano-magnetite

A technology of vanadium-titanium magnetite and ilmenite, which is applied in blast furnaces, furnace types, blast furnace details, etc., can solve the problems of long pelleting time, poor quality of green pellets, and low strength of cooked pellets, and achieve small water loss , short time and low roasting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

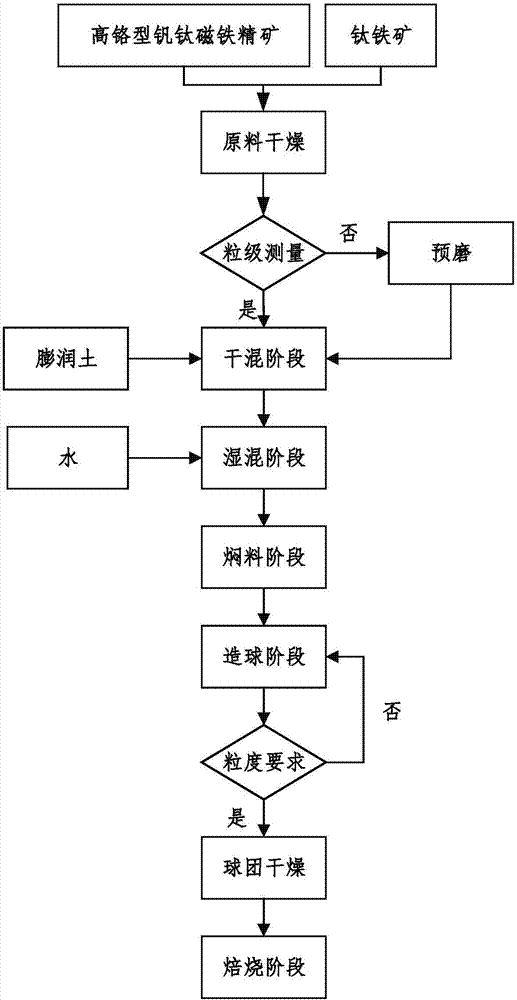

[0045] A method for preparing pellets by adding ilmenite to high chromium type vanadium-titanium magnetite, such as figure 1 As shown, the method includes:

[0046] 1. Raw material drying

[0047] Dry high-chromium vanadium-titanium magnetite, ilmenite and bentonite in a drying oven at a drying temperature of 104-108°C and a drying time of 3-4.5 hours to make high-chromium vanadium-titanium magnetite and titanium The moisture content of iron ore is less than or equal to 1.5%.

[0048] It has been tested that the moisture content of high-chromium vanadium-titanium magnetite and ilmenite powder is in the range of 1.2% to 1.5%, which is the crystal water content, and that which exceeds this range is free water; in order to avoid free water from affecting the dry mixing effect, such as bentonite absorption The moisture in the high-chromium vanadium-titanium magnetite will agglomerate together and reduce the mixing effect with the high-chromium vanadium-titanium magnetite; at the...

Embodiment 2

[0072] A kind of high chromium type vanadium-titanium magnetite is mixed with the method for adding ilmenite to prepare pellets, the present embodiment is on the basis of embodiment 1, and concrete operation steps are as follows:

[0073] 1. Raw material drying

[0074] Get 4.5kg high-chromium type vanadium-titanium magnetite, 0.5kg ilmenite, and bentonite is 1% of the high-chromium type vanadium-titanium magnetite and ilmenite gross weight, and it is dried in a drying box. The temperature is 105°C, and the drying time is 4 hours. After drying, the water content of high-chromium vanadium-titanium magnetite is 1.2%, and that of ilmenite is 1.4%. Among them, the particle size distribution of high-chromium vanadium-titanium magnetite and ilmenite was measured by wet sieving method. Among the high-chromium vanadium-titanium magnetite, the proportion of particle size less than 75 μm was 72%; the particle size of ilmenite was less than The proportion of 75μm is 92%.

[0075] 2. Mi...

Embodiment 3

[0090] This embodiment is on the basis of embodiment 1, concrete operation is as follows:

[0091] 1. Raw material drying

[0092] Get 4.4kg high-chromium type vanadium-titanium magnetite, 0.6kg ilmenite and calcium-based bentonite account for 1.2% of the high-chromium type vanadium-titanium magnetite weight, these three kinds of raw materials are carried out drying process in drying box, drying temperature The temperature is 106°C, and the drying time is 3.4 hours. After drying, the water content of high-chromium vanadium titanomagnetite and ilmenite is 1.25% and 1.3%. Among them, the particle size distribution of high-chromium vanadium-titanium magnetite and ilmenite was measured by wet sieving method. Among the high-chromium vanadium-titanium magnetite, the proportion of particle size less than 75 μm was 72%; the particle size of ilmenite was less than The proportion of 75μm is 82%.

[0093] 2. Mixing stage

[0094] The hydrogen-based bentonite was added to the high-chro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com