A method and device for producing metal vanadium by carbothermal reduction

A metal and carbothermal technology, applied in the field of carbothermal reduction to produce metal vanadium, can solve the problems of high cost, easy oxidation of potassium, and many electrolysis processes, and achieve the effect of saving resources and reducing impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

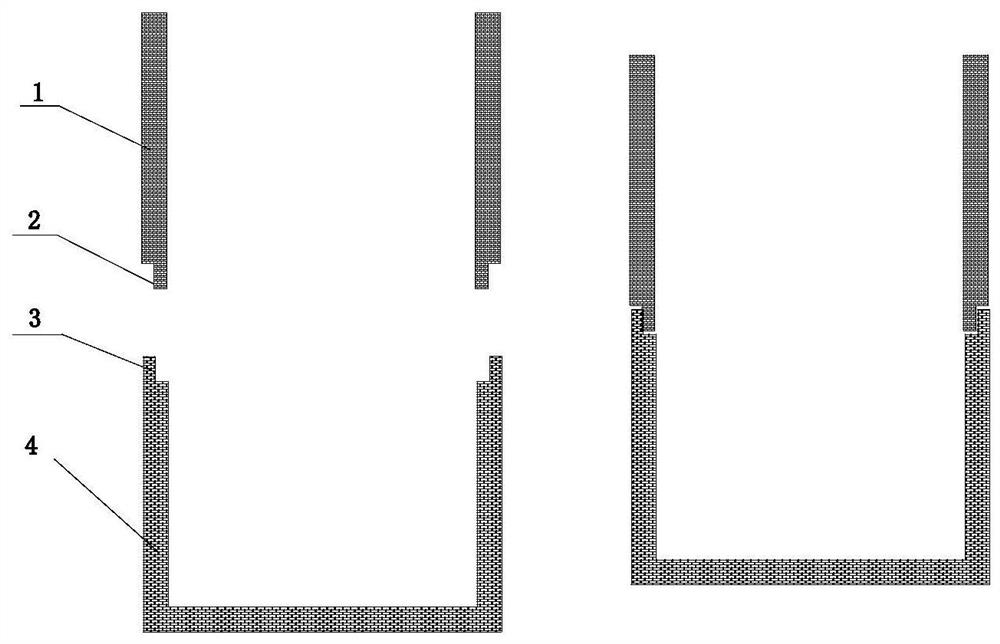

Image

Examples

Embodiment 1

[0051] This embodiment provides a method for carbon reduction to produce metal vanadium, the method comprising:

[0052] (1) Mix vanadium pentoxide with a particle size of 40 mesh and graphite with a particle size of 80 mesh according to the molar ratio of carbon and oxygen elements of 1.1:1 and press into balls, and carry out reduction smelting to obtain low-priced vanadium oxide or low-priced Vanadium carbides;

[0053] (2) crushing the low-valent vanadium oxide and / or low-valent vanadium carbide obtained in step (1) to 40 mesh, and detecting the content of carbon element and oxygen element;

[0054] (3) According to the test result of step (2), use graphite to carry out carbon matching to the mol ratio of carbon element and oxygen element is 1:1, after mixing, the mixture is obtained, and the obtained mixture is pressed into balls, and the mixture is Carry out vacuum refining at a vacuum degree of 0.1Pa, the temperature of vacuum refining is 1700°C, the heating rate is 4°C...

Embodiment 2

[0057] This embodiment provides a method for carbon reduction to produce metal vanadium, the method comprising:

[0058] (1) Mix vanadium pentoxide with a particle size of 200 mesh and graphite with a particle size of 300 mesh according to the molar ratio of carbon and oxygen elements of 1.2:1 and press them into balls, and carry out reduction smelting to obtain low-priced vanadium carbides or low-valence vanadium carbides. Vanadium carbides;

[0059] (2) crushing the low-valent vanadium oxide and / or low-valent vanadium carbide obtained in step (1) to 200 mesh, and detecting the content of carbon element and oxygen element;

[0060] (3) according to the test result of step (2), it is 1:1 to mix vanadium pentoxide to the mol ratio of carbon element and oxygen element. The material is vacuum refined at a vacuum degree of 0.1Pa. The temperature of the vacuum refining is 1780°C, the heating rate is 4°C / min, the time is 3h, and the argon flow is cooled to 50°C to obtain a metal va...

Embodiment 3

[0063] This embodiment provides a method for carbon reduction to produce metal vanadium, the method comprising:

[0064] (1) Mix vanadium pentoxide with a particle size of 80 mesh and graphite with a particle size of 120 mesh according to the molar ratio of carbon and oxygen elements of 1.15:1 and press into balls, and carry out reduction smelting to obtain low-priced vanadium oxide or low-priced Vanadium carbides;

[0065] (2) crushing the low-valent vanadium oxide and / or low-valent vanadium carbide obtained in step (1) to 50 mesh, and detecting the content of carbon element and oxygen element;

[0066] (3) according to the test result of step (2), it is 1:1 to mix vanadium pentoxide to the mol ratio of carbon element and oxygen element. The material is vacuum refined at a vacuum degree of 0.1Pa. The temperature of the vacuum refining is 1730°C, the heating rate is 4°C / min, the time is 5h, and the argon flow is cooled to 50°C to obtain a metal vanadium product.

[0067] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com