Double-layer laminated type prefabricated pavement and construction method thereof

A double-layer superimposed and prefabricated assembly technology, which is applied to pavement, roads, roads and other directions paved with prefabricated blocks, can solve the problems of difficult transportation of prefabricated asphalt panels and difficult joint connection, etc., to improve drainage efficiency and protect integrity , the effect of solving the seam problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The double-layer laminated prefabricated pavement of the present invention is adopted on a highway

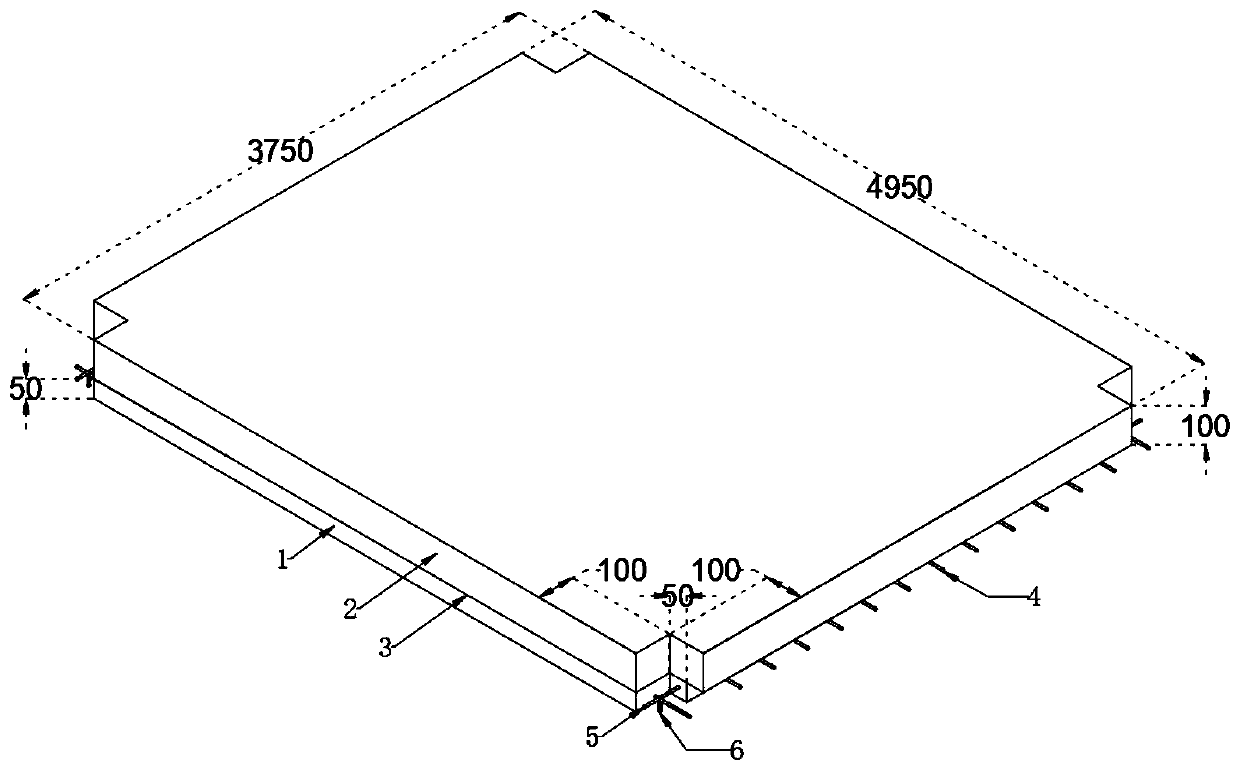

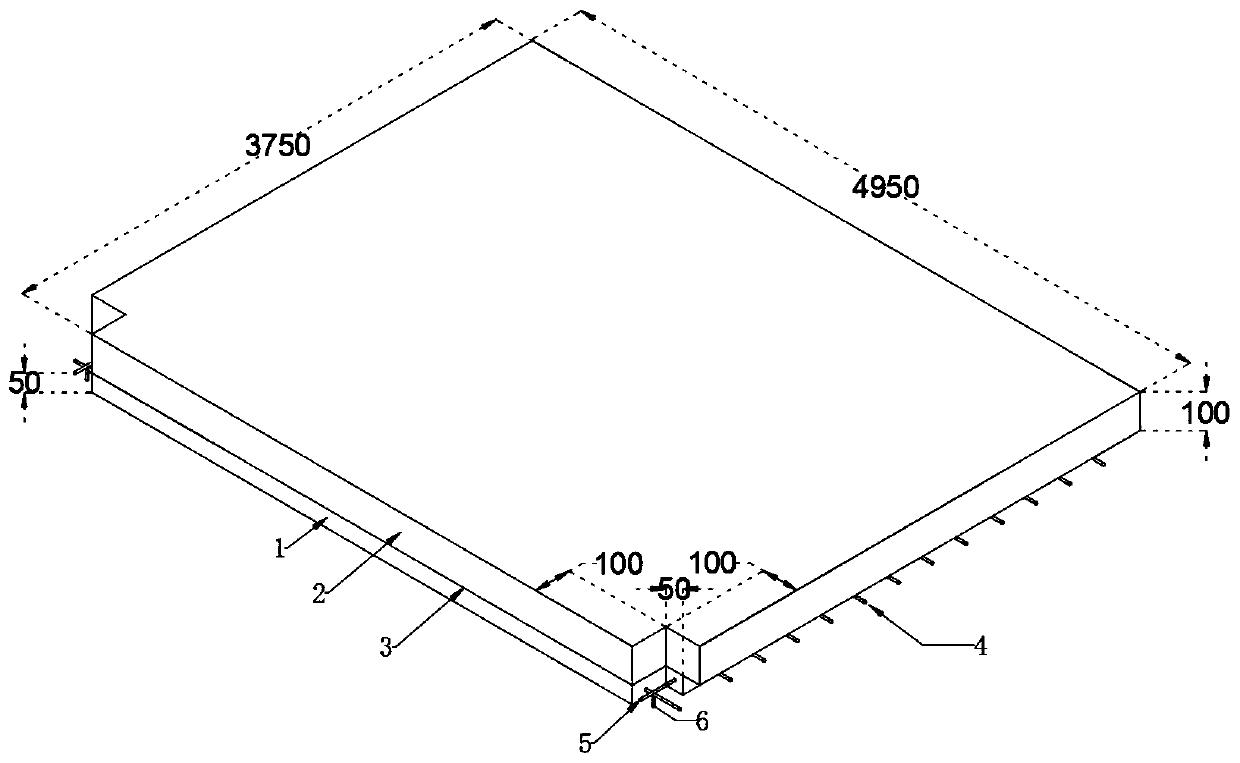

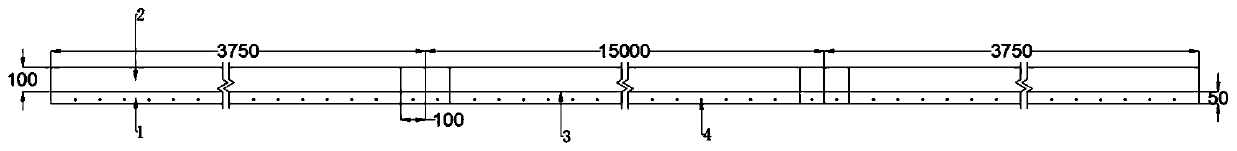

[0047] The double-layer laminated prefabricated pavement used in this embodiment includes a structural unit composed of a concrete base 1 and a modified asphalt panel 2 .

[0048] The concrete base 1 is arranged inside the road and has a square notch at the four corners of the edge, and is arranged on the outside of the road and has a square notch at two corners on one side of the longitudinal direction; Reserve the construction space and serve as the entrance for pouring the fast-setting self-compacting concrete 7 . In this embodiment, the size of the concrete base 1 is 4850mmL×3750mm W×100mm H, the gap of the base is 50mm in the longitudinal direction and 100mm in the transverse direction; the size of the modified asphalt panel 2 is 4950mmL×3750mm W×100mm H, the modified asphalt panel The gap of 2 is 100mm vertically and 100mm horizontally. The concrete base 1 is a s...

Embodiment 2

[0068] A highway adopts the double-layer laminated prefabricated pavement of the present invention, which includes a structural unit composed of a concrete base and a modified asphalt panel. The construction method at the bend is as follows.

[0069] The concrete base is arranged inside the road with square notches at the four corners of the edge, and at the outside of the road is provided with square notches at the two corners of the longitudinal side; the setting of the notch leaves room for the connection between the longitudinal dowel bar and the transverse tie rod. space and as an entrance for pouring fast-setting self-compacting concrete. In this embodiment, the size of the concrete base and the modified asphalt panel is calculated and adjusted according to the radius of curvature of the curve. The notch of the base is 50 mm in the longitudinal direction and 100 mm in the transverse direction, and the notch of the modified asphalt panel is 100 mm in the longitudinal dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com