Sectional steel pulling-out method for SMW construction method pile

A technology of construction method piles and I-shaped steel, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of stirring wall cracking and pulling up section steel efficiency, and achieve the effect of ensuring speed, improving work efficiency, and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] This embodiment further describes the present invention in detail in conjunction with the accompanying drawings.

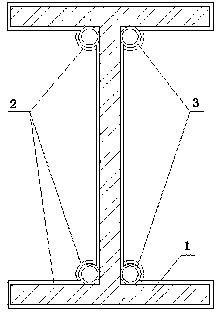

[0031] figure 1 It is a schematic diagram of PVC sleeve wrapping I-shaped steel. Among them, 1 is I-shaped steel; 2 is PVC sleeve; 3 is grouting pipe. Such as figure 1 As shown, grouting pipes with the same length as the I-shaped steel web are left at the four corners of the I-shaped steel web; the surface of the I-shaped steel is covered with a PVC sleeve with the same inner cavity shape as the outer surface of the I-shaped steel The unit length of the I-shaped steel is welded into a whole, and the PVC sleeve is connected by an adhesive to wrap the entire I-shaped steel and the grouting pipe. The I-shaped steel needs to be 20-30 cm higher than the PVC pipe.

[0032] figure 2 is a schematic diagram of a cement-soil mixing pile, wherein 4 is a cement-soil mixing pile.

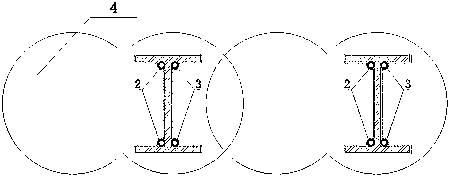

[0033] image 3 It is a schematic plan view of the I-shaped steel and PVC sleeve i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com