A hot air drying device for non-woven fabric production

A technology of hot air drying and non-woven fabrics, applied in the directions of drying, drying machine, drying gas arrangement, etc., can solve the problems of low drying efficiency and low thermal conductivity, improve drying efficiency, and remove moisture. , the effect of preventing curling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

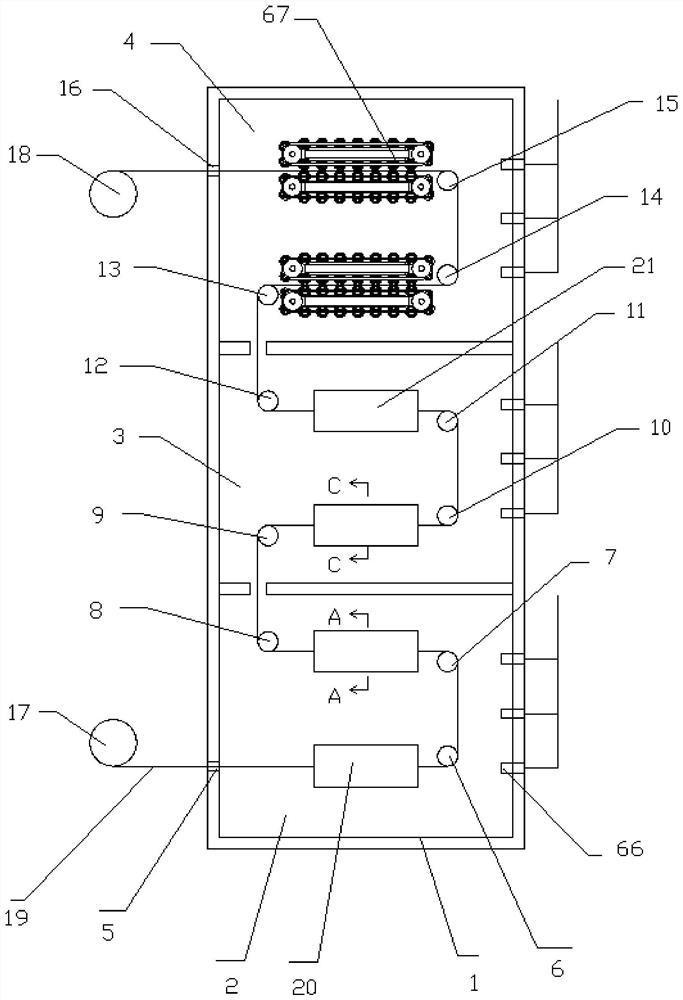

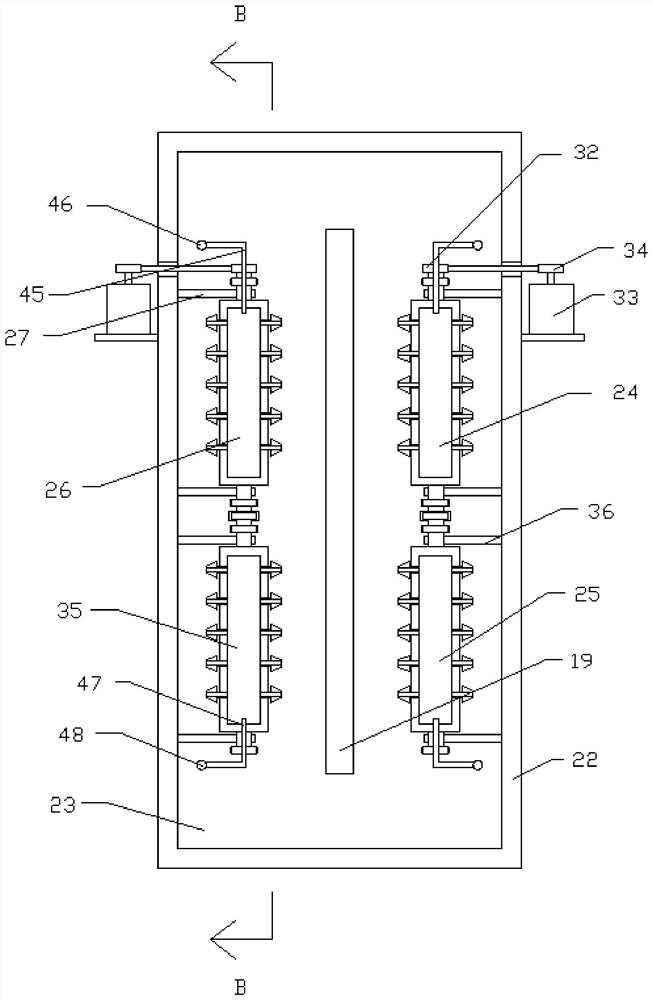

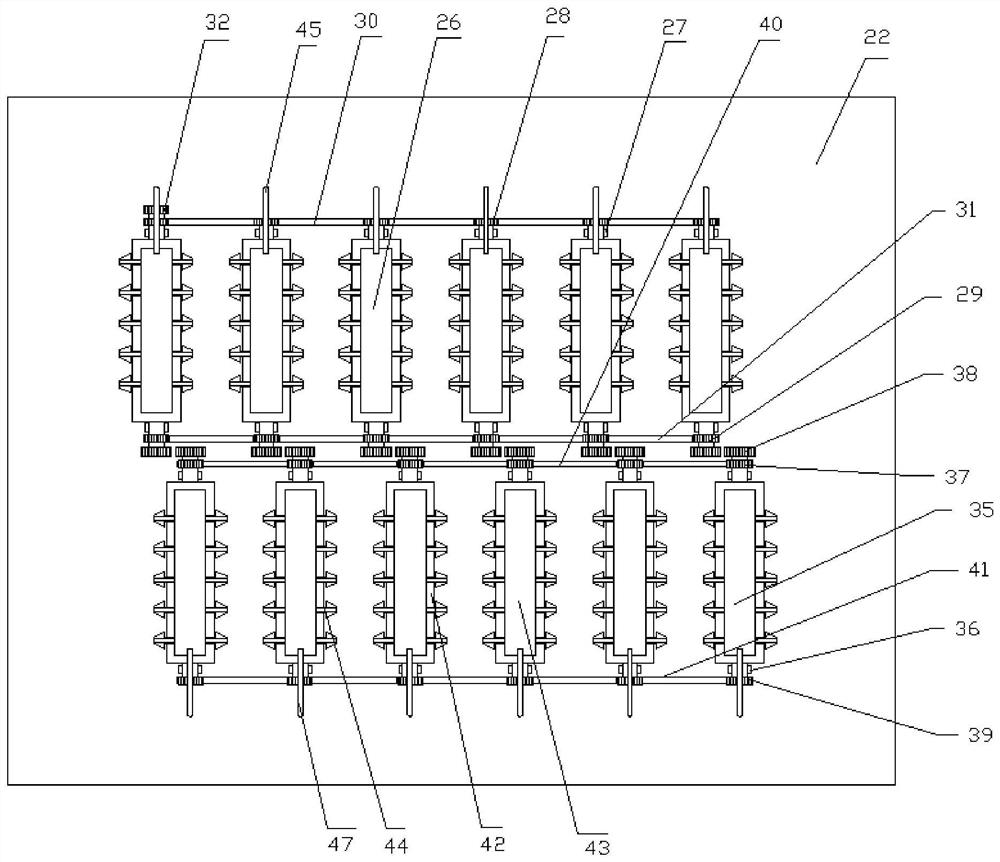

[0048] As shown in the figure, a hot air drying device for non-woven fabric production includes a casing 1, and the casing is provided with a first drying cavity 2, a second drying cavity 3 and a third drying cavity in sequence from the back to the front. 4;

[0049] There is a feeding port 5 on the left side wall of the first drying chamber, and a first turning roller 6, a second turning roller 7 and a third turning roller 8 are vertically and rotatably arranged in the first drying chamber; A turning roller is correspondingly arranged on the right side of the feeding port, the second turning roller is correspondingly arranged in front of the first turning roller, and the third turning roller is correspondingly arranged on the left side of the second turning roller;

[0050] The second drying cavity is vertically and rotatably provided with a fourth turning roll 9, a fifth turning roll 10, a sixth turning roll 11 and a seventh turning roll 12; the fourth turning roll is corres...

Embodiment 2

[0075] As shown in the figure, a hot air drying device for non-woven fabric production includes a shell, and the shell is provided with a first drying cavity, a second drying cavity and a third drying cavity in sequence from the back to the front;

[0076] A feeding port is provided on the left side wall of the first drying chamber, and a first turning roller, a second turning roller and a third turning roller are vertically and rotatably arranged in the first drying chamber; the first turning roller corresponds to It is arranged on the right side of the feeding port, the second steering roller is correspondingly arranged in front of the first steering roller, and the third steering roller is correspondingly arranged on the left side of the second steering roller;

[0077] The second drying cavity is vertically and rotatably provided with a fourth turning roll, a fifth turning roll, a sixth turning roll and a seventh turning roll; the fourth turning roll is correspondingly arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com