An internal circulation grain drying tower

A technology of internal circulation and drying tower, which is applied in the direction of drying, drying machine, non-progressive drying machine, etc., can solve the problems of heat loss, less than 30%, and the overall efficiency reduction of equipment, so as to reduce the loss of tower temperature , reduce drying costs, and achieve the effect of repeated use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the technical solution of this embodiment will be described in detail below in conjunction with the accompanying drawings. The following embodiments are only used to illustrate the technical solution of this embodiment more clearly, so they are only examples, and should not be used to limit the protection scope of this embodiment.

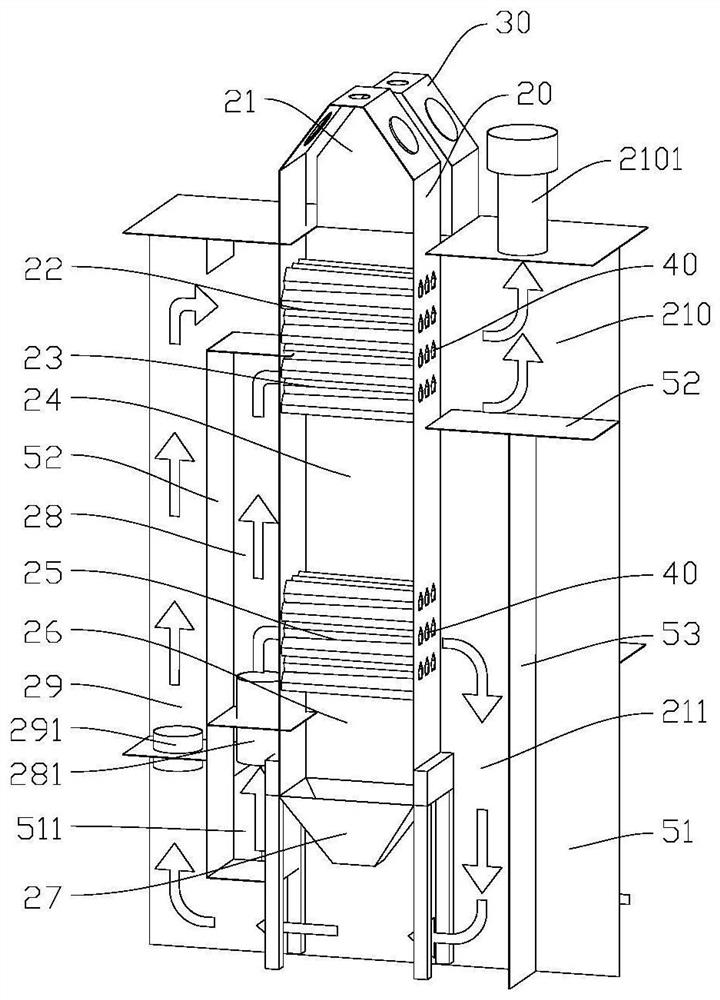

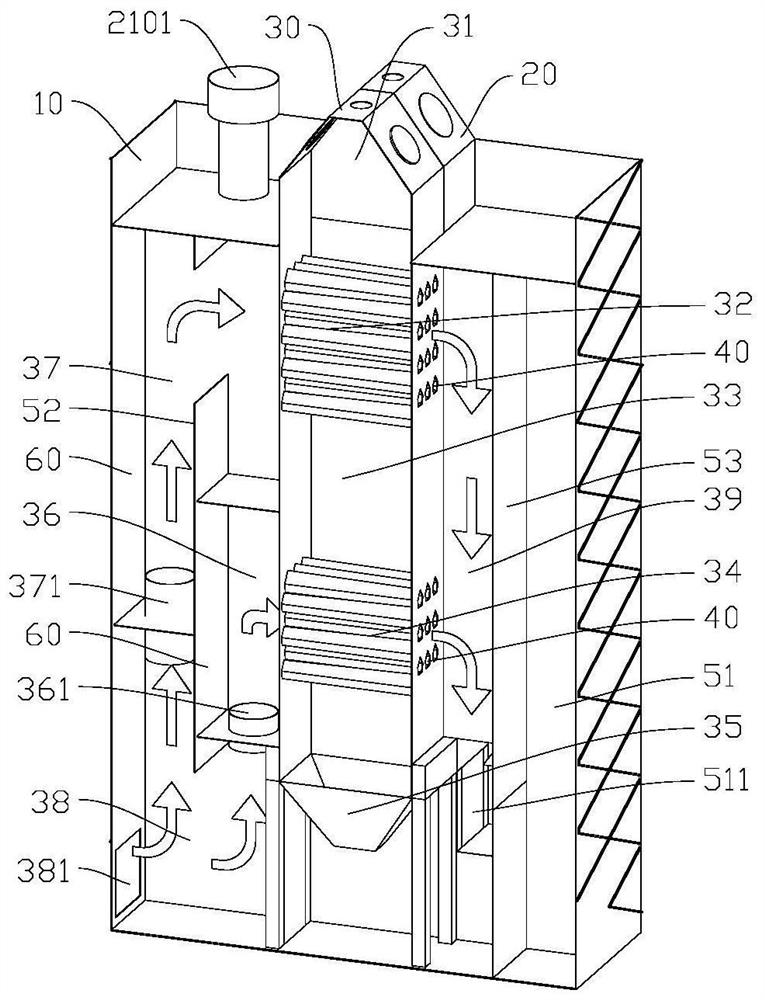

[0021] Such as Figure 1-Figure 5 As shown, the embodiment of the present invention provides an internal circulation grain drying tower, including a drying bin body 10, a first-stage drying bin 20 and a second-stage drying bin 30 disposed in the drying bin body 10, and an elevator (not shown in the figure).

[0022] refer to figure 1 , a section of drying bin 20 is provided with a section of grain inlet 21, a preheating section 22, a section of drying section 23, a section of slow drying section A24, a section of drying section 25, a section of slow drying section B26 and a section of grain output from top to bottom. Port 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com