Multi-layer heating oil burning boiler

A technology for oil-fired boilers and boiler bodies, applied in the field of boilers, can solve the problems of inaccurate temperature control, low thermal energy utilization, energy waste, etc., and achieve the effects of making full use of full control, protecting the environment, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

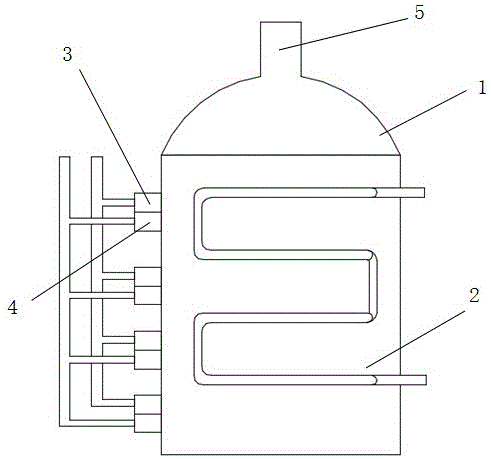

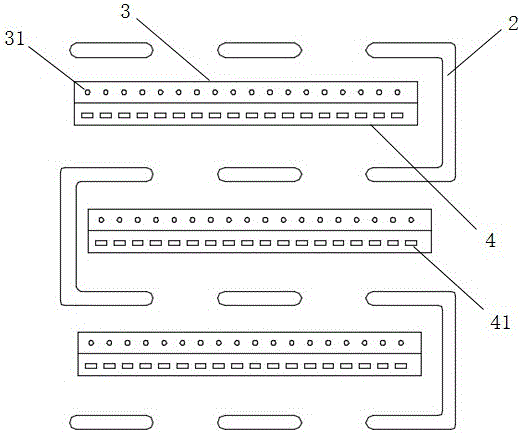

[0023] Embodiment 1: A multi-layer heating oil-fired boiler, including a boiler body 1, which is provided with at least two layers of heating coils 2; the outer wall of the boiler body 1 is located at a position below the heating coils 2 A combustion device 3 is provided, and the combustion device 3 is capable of spraying flames below the heating coil 2 .

Embodiment 2

[0024] Embodiment 2: A multi-layer heating oil-fired boiler, including a boiler body 1, and at least two layers of heating coils 2 are arranged inside the boiler body 1; the outer wall of the boiler body 1 is located below the heating coil 2 A combustion device 3 is provided, and the combustion device 3 can inject flames to the lower part of the heating coil 2, and the heating coil 2 is provided with four layers.

Embodiment 3

[0025] Embodiment 3: A multi-layer heating oil-fired boiler, including a boiler body 1, and at least two layers of heating coils 2 are arranged inside the boiler body 1; the outer wall of the boiler body 1 is located below the heating coil 2 A combustion device 3 is provided, and the combustion device 3 can spray flames to the bottom of the heating coil 2 , and an air blast device 4 is provided on the outer wall of the boiler body 1 below the combustion device 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com