Fuel transferring and heating device

A heating device and transfer technology, which is applied in the direction of propulsion engine, transportation and packaging, ship propulsion, etc., can solve the problems of increasing the difficulty of ship construction by steam coil, regular maintenance of steam coil damage, and increasing the cost of ship maintenance, etc. Achieve the effect of improving heat utilization efficiency, stable installation, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

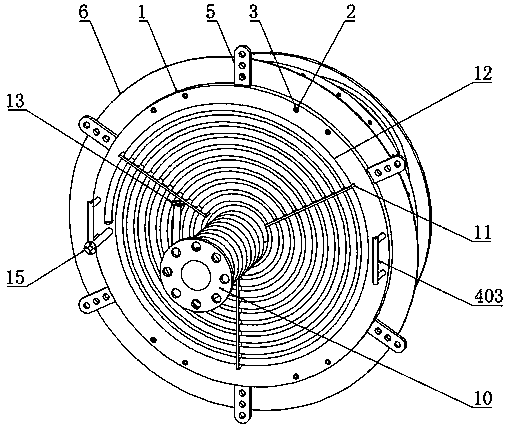

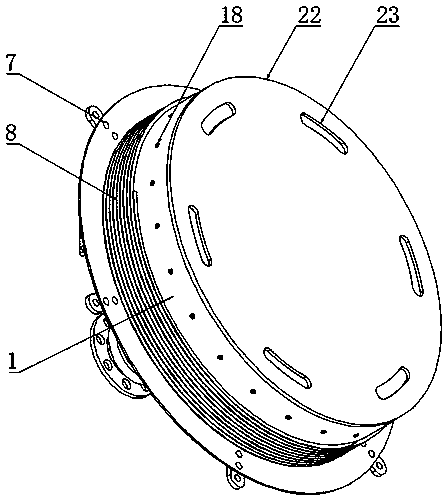

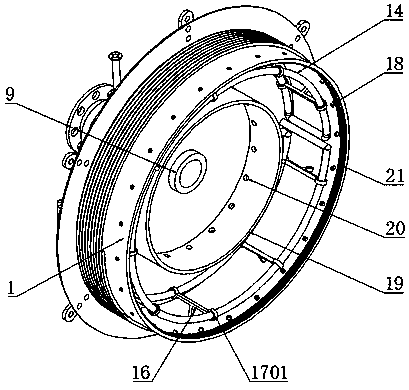

[0031] Example: such as Figure 1-6 As shown, the present invention provides a technical solution, a fuel oil transfer heating device, including a main housing 1, a fitting hole 2 is opened on the edge of the front end of the main housing 1, and a fixing hole 2 is installed at the inner bottom of the fitting hole 2. Column 3, the front end of the main housing 1 is equipped with a handle mechanism 4 through the fitting hole 2, the handle mechanism 4 includes a vertical rod 401, a mounting groove 402 and a handle rod 403, the bottom end of the vertical rod 401 is provided with a mounting groove 402, and the top end of the vertical rod 401 A handle rod 403 is installed. In order to ensure that when the handle rod 403 is pushed, the vertical rod 401 can effectively drive the main housing 1 to rotate, so as to realize the installation and disassembly of the main housing 1. The outer diameter of the vertical rod 401 and the inner diameter of the fitting hole 2 The inner diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com