A plasma processing device and its adjustment method

A plasma and processing device technology, applied in the field of plasma processing devices and its adjustment, can solve the problems of poor etching alignment in the edge area of the substrate to be processed, difficulty in adjusting the height of the focus ring, and etching alignment at the edge of the substrate to be processed. Difficult to adjust online and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

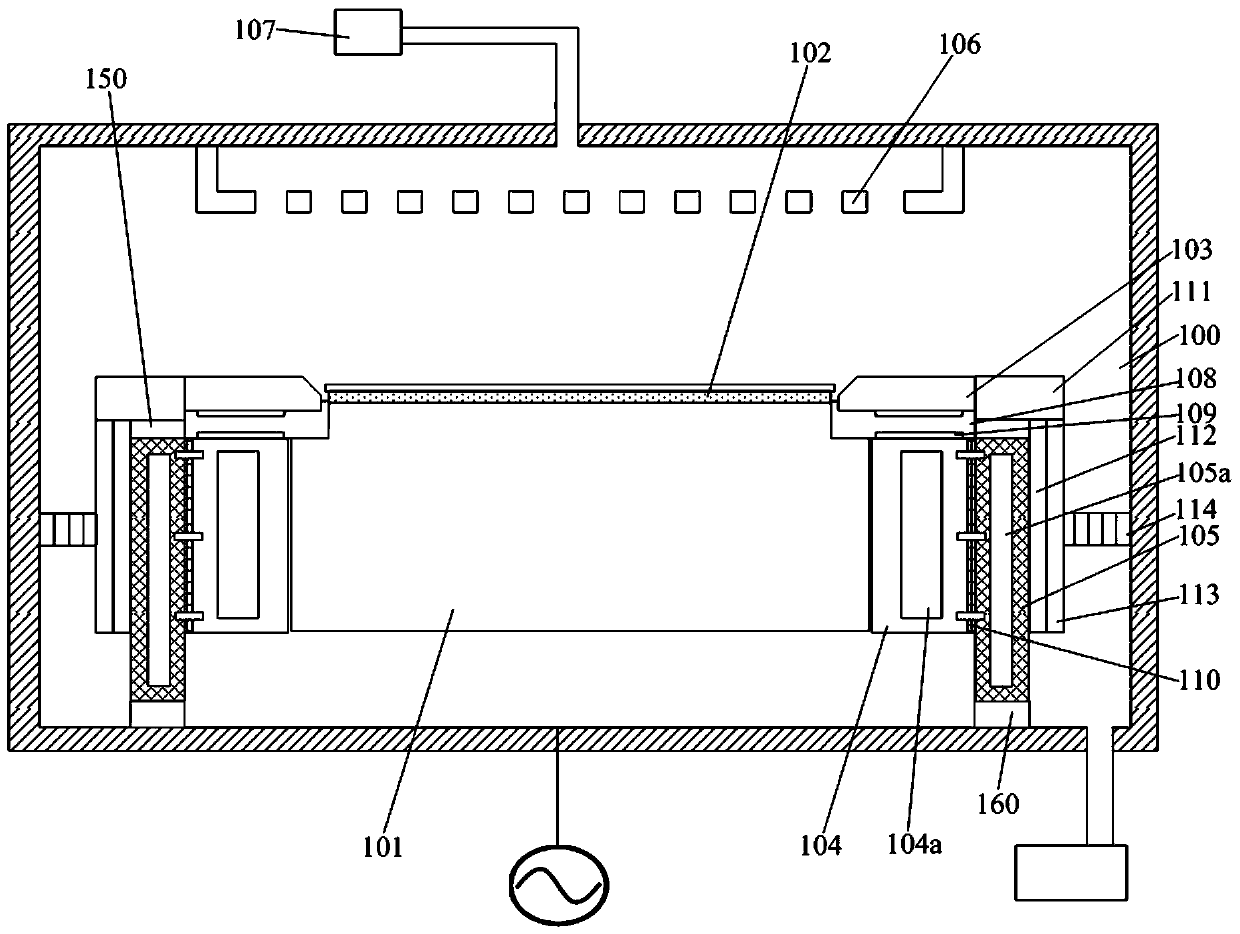

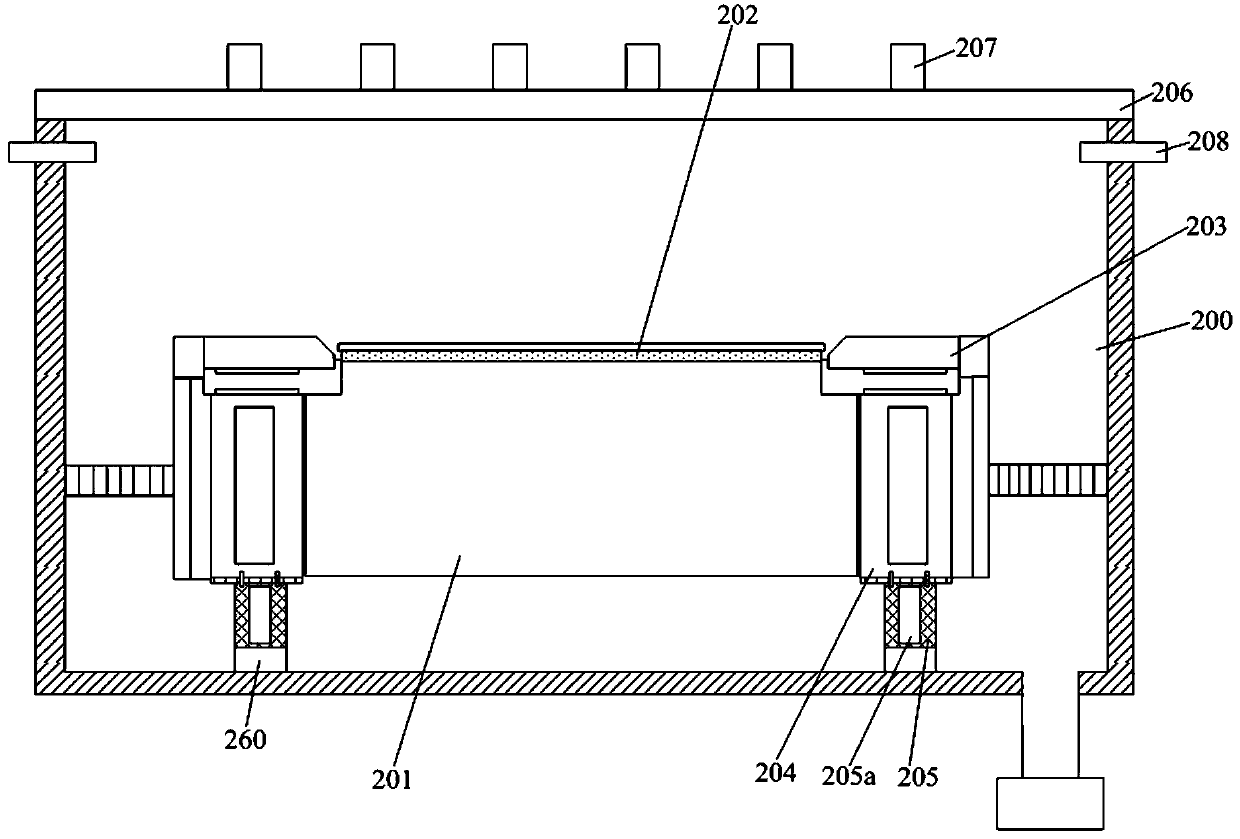

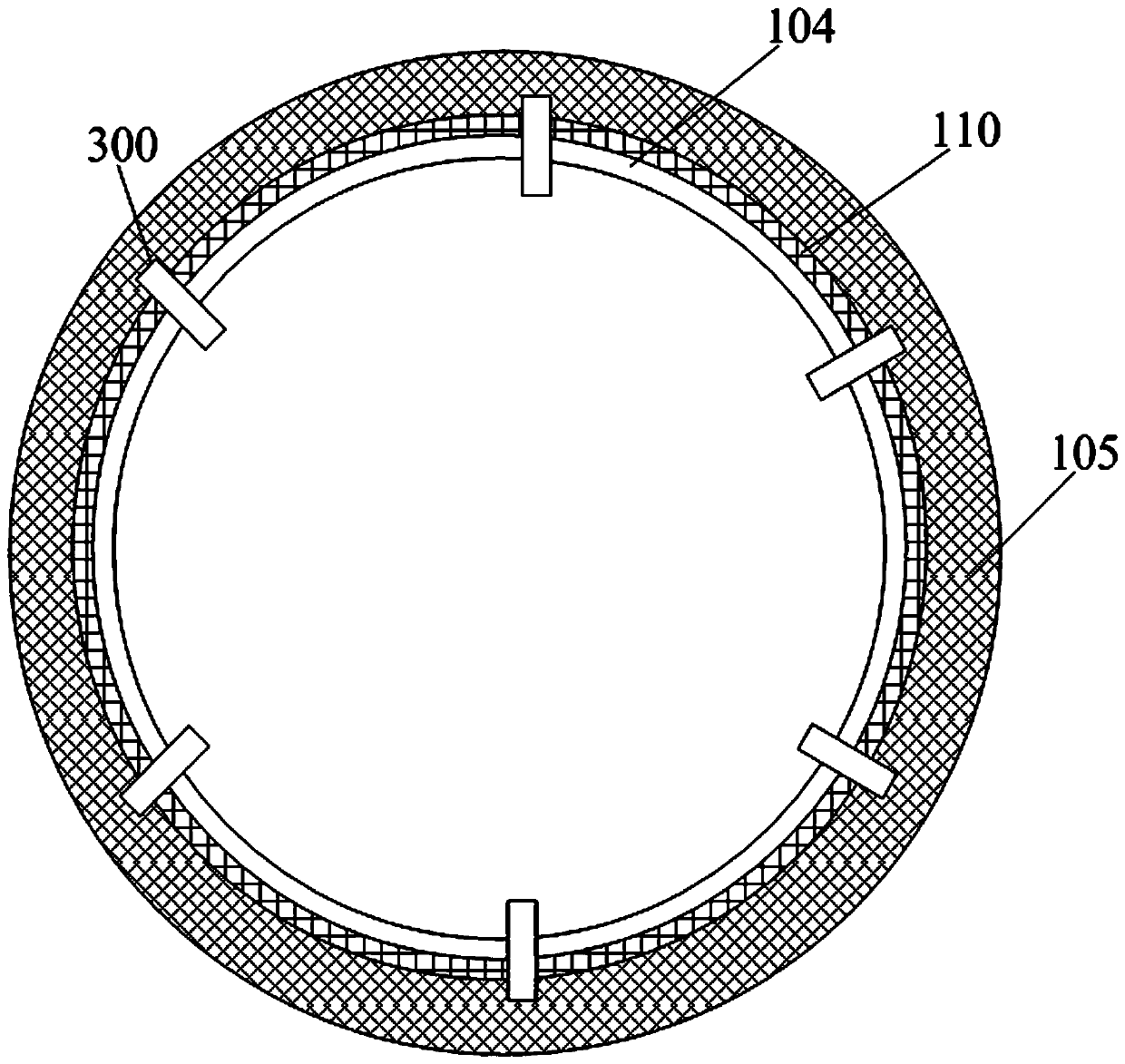

[0031] As described in the background art, it is difficult for the existing plasma processing device to adjust the alignment of the edge etching of the substrate to be processed. In order to solve the above technical problem, the technical solution of the present invention provides a plasma processing device, including: a processing chamber; The base is located at the bottom of the processing chamber; the electrostatic chuck is located on the base and is used to carry and adsorb the substrate to be processed; the focus ring surrounds the electrostatic chuck; the heat conduction ring is located at the focus Below the ring and surrounding the base; an expandable member connected to the heat conduction ring, the expandable member comprising a material with a high thermal expansion coefficient, a first fluid groove in the expandable member, the first fluid The groove is used to contain the first fluid. The plasma processing device can dynamically adjust the etching collimation of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com