Multi-spray-head pressing type 3D printer and printing method

A 3D printer, compact technology, applied in the direction of 3D object support structures, manufacturing tools, coating devices, etc., can solve the problem of items that are not suitable for printing powdery raw materials, not suitable for printing metal molds, and can not solve the problem of layer and layer. Combining problems and other problems to achieve the effect of improving printing efficiency, combining tightness and preventing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

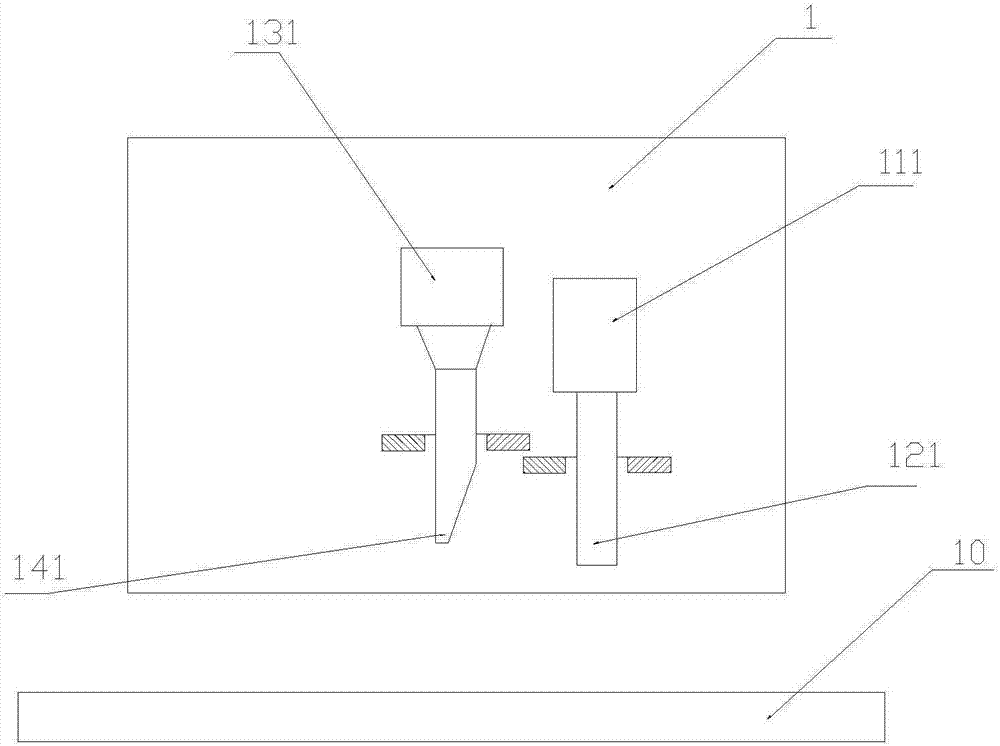

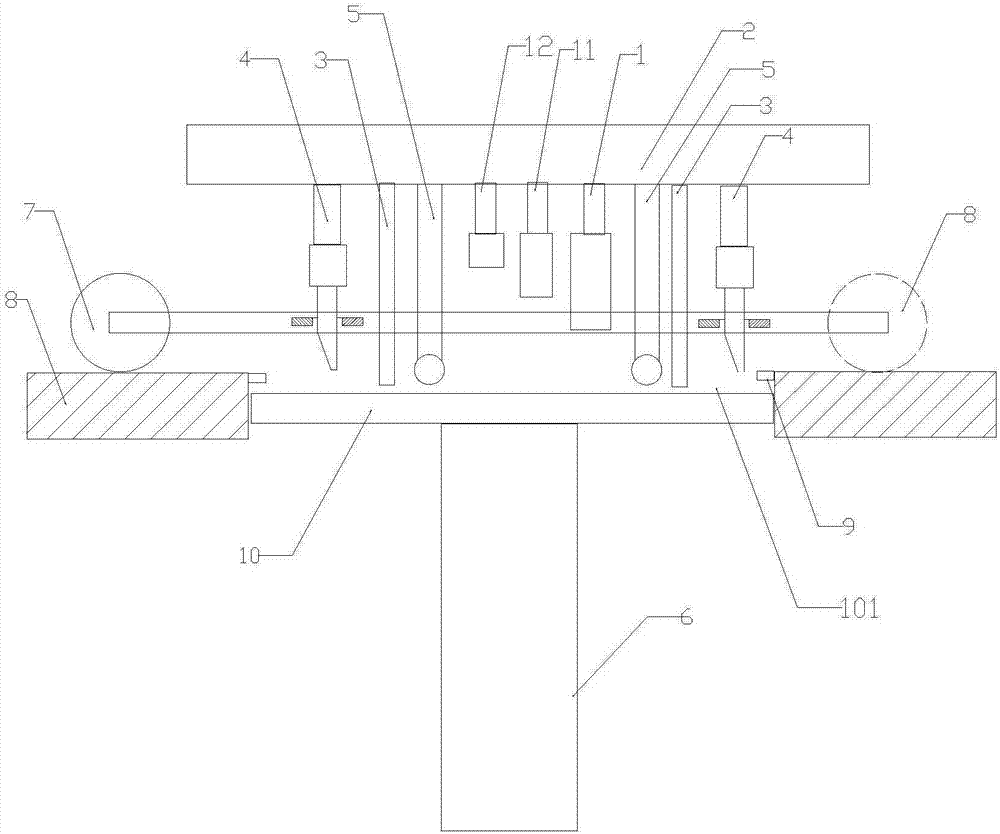

[0042] see Figure 1-3 , this embodiment discloses a multi-nozzle compact 3D printer, which includes a mobile platform 10, a vacuum chamber, and a plurality of printing modules 1, 11, 12, . . . , N. The plurality of printing modules are all arranged in a vacuum chamber, and are arranged sequentially above the mobile platform 10, the printing module 1 with the smallest distance from the moving platform 10 is the first printing module, and the printing module 1 next to the first printing module 1 The printing module is the second printing module 11, and so on, and the printing module with the largest distance from the mobile platform 10 is the Nth printing module. The above-mentioned mobile platform 10 is a horizontally arranged platform that can be raised and lowered. A plurality of the printing modules are sequentially arranged in a straight line above the mobile platform 10, and from the first printing module 1 to the Nth printing module, the distance between the moving The ...

Embodiment 2

[0051] Such as Figure 4As shown, the difference from Embodiment 1 is that a polygonal through hole is set in the middle of the fixed platform 8 of this embodiment, preferably a rectangular through hole, and the shape of the mobile platform 10 is the same as that of the through hole. 10 is placed in the through hole and clings to the inner wall of the through hole. A printing cavity 101 is formed between the moving platform 10 and the inner wall of the through hole, and the printing module realizes reciprocating layer-by-layer printing in the printing cavity 101 .

Embodiment 3

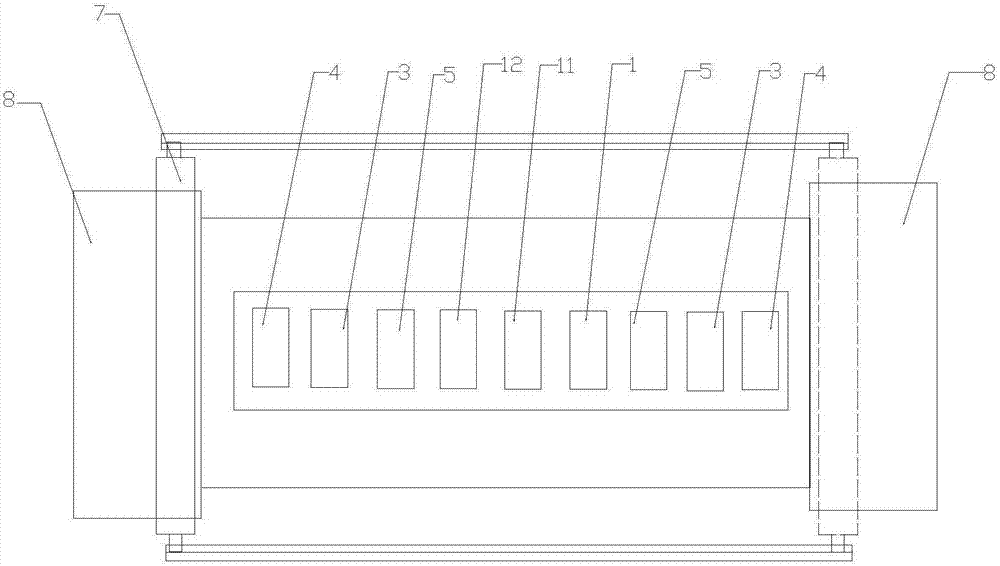

[0053] see Figure 5 and 6 , this embodiment discloses a multi-nozzle compact 3D printer, which includes a mobile platform 10, a vacuum chamber, and multiple printing modules 1, 11, 12...,N. The plurality of printing modules are all arranged in a vacuum chamber, and are arranged sequentially above the mobile platform 10, the printing module 1 with the smallest distance from the mobile platform 10 is the first printing module, and the distance between the mobile platform 10 and the printing module 1 is the first printing module. The printing module 11 with the next smallest distance is the second printing module, and so on, the printing module with the largest distance from the mobile platform 10 is the Nth printing module.

[0054] The difference from Embodiment 1 is that the mobile platform 10 of this embodiment is circular, and the fixed platform 8 is provided with a circular through hole, and the mobile platform 10 moves up and down in the circular through hole, and is in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com